6. Bring together the blade shafts (B) and finish the

procedure by greasing the nipples (D) until

grease is coming out around the blade shafts

(B).

Cleaning the pressure plate

Check the status of the lubrication of the bearings.

Use the same grease as for the shafts.

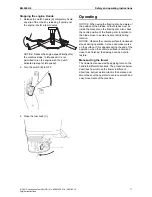

1. Loosen and remove the screw (A) and the

washer (B).

A

B

C

D

E

F

2. Dismount the spider assembly (C). Use a puller

if the blade cross is tight on the shaft.

3. Dismount the pressure plate (D), protection ring

(E) and the needle bearing (F).

4. Clean the surfaces and grease them carefully.

5. Assemble the parts.

NOTICE

The gearbox of the trowel is lubricated for

life. If the oil for some reason has to be changed,

use recommended oil quality. See section "Technical

data".

Troubleshooting

Solution

Cause

Problem

Turn the switch on.

Start switch in off

position.

The trowel does not

start.

Open the fuel cock.

Fuel cock off.

Fill up the tank.

Fuel tank empty.

Activate the choke.

Cold engine

See engine manual.

Engine faulty.

Replace the V-belt

The V-belt is

broken.

The blades do not

rotate or rotate too

slow, when the

clutch handle is

activated.

Adjust the

tensioning of the

clutch wire.

The V-belt is

slipping or does not

tension against the

pulleys.

Replace the clutch

wire.

The clutch wire is

broken.

Solution

Cause

Problem

Warm the engine up

at idle speed.

Cold engine.

The blade cross has

difficulty rotating.

Increase r.p.m.

To low r.p.m. when

activating the

clutch.

Wait until the

concrete has dried

a little.

Floating disc is

used and the

concrete is too

fresh.

See engine manual.

Engine faulty.

Repair or replace

the gearbox.

Gearbox faulty.

Replace the broken

units.

One or more blades

are bent or faulty.

The trowel is

shaking.

Disassemble the

blades and clean

the contact area.

Put new grease on

all contact areas.

One or more blades

are not moving in

the hub.

Replace the

pressure plate.

The pressure plate

is askew.

Replace the clutch

wire.

The clutch wire is

broken.

The blade

adjustment system

is out of order.

Disassemble the

blades and clean

the contact area.

Put new grease on

all contact areas.

One or more of the

blades are not

moving in the hub.

Disassemble the

blade cross and

clean all contact

areas.

The pressure plate

is not moving

vertically.

Check all involved

parts and replace if

necessary.

The blade

adjustment in the

operating handle is

faulty.

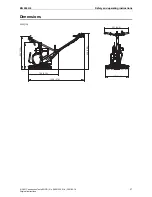

Storage

●

Clean the machine properly before storage, in

order to avoid hazardous substances. See “Dust

and fume hazard”.

●

If the machine is stored in the service position, the

fuel tank must not be filled more than half full.

Otherwise there is a risk that the fuel can come

out through the ventilation hole in the fuel tank

cap.

●

Always store the machine in a dry place.

Disposal

A used machine must be treated and disposed of in

such a way that the greatest possible portion of the

material can be recycled and any negative influence

on the environment is kept as low as possible, and

in accordance with local restrictions.

23

© 2051 Construction Tools EOOD | No. 9800 1224 01b | 2051-05-18

Original instructions

Safety and operating instructions

BG 240 H4