♦

To increase the blade angle, turn the twist pitch

knob clockwise.

♦

To decrease the blade angle, turn the twist pitch

knob counterclockwise.

When taking a break

♦

Stop the machine during breaks.

♦

During all breaks, put the machine away so that

there is no risk for unintentional start.

Maintenance

Regular maintenance is a basic requirement for the

continued safe and efficient use of the machine.

Follow the maintenance instructions carefully.

♦

Before starting maintenance on the machine, clean

it in order to avoid exposure to hazardous

substances. See “Dust and fume hazard”.

♦

Use only authorised parts. Any damage or

malfunction caused by the use of unauthorised

parts is not covered by warranty or product liability.

♦

When cleaning mechanical parts with solvent,

comply with appropriate health and safety

regulations and ensure there is satisfactory

ventilation.

♦

For major service of the machine, contact the

nearest authorised workshop.

♦

After each service, check that the machine's

vibration level is normal. If not, contact the nearest

authorised workshop.

NOTICE

Never aim a water jet directly at the fuel

filler cap. This is particularly important when using a

high-pressure cleaner.

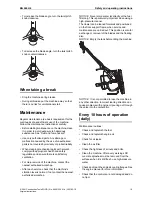

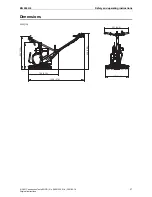

The trowel can be leaned forwards and positioned

on the front support frame, when service and

maintenance are carried out. This position is also for

exchange or removal of the blades and the floating

disc.

NOTICE

Empty the tank before tilting the machine.

NOTICE

It is not permitted to lean the machine in

any other direction. Incorrect leaning direction can

cause problems with engine oil pouring out through

the valve into the carburettor.

Every 10 hours of operation

(daily)

Maintenance routines:

♦

Check and replenish the fuel.

♦

Check and replenish engine oil.

♦

Check for oil leaks.

♦

Clean the air filter.

♦

Check the tightness of all nuts and bolts.

♦

Clean the machine. After every working shift

concrete splashes must be removed from the

surfaces when it is still fresh, use high-pressure

water.

♦

Check and clean the engine's cooling flanges. See

the engine manual for more information.

♦

Check that the controls are not damaged and do

not jam.

19

© 2051 Construction Tools EOOD | No. 9800 1224 01b | 2051-05-18

Original instructions

Safety and operating instructions

BG 240 H4