3) Check the gap between Ribbon Guide and Head Nose

again, by inserting above thickness gauge.

The gauge should be inserted smoothly. If not,

back to 2.

2. Adjustment & Replacement of Ribbon Gear Ass'y

2-1 Disassemble and assemble

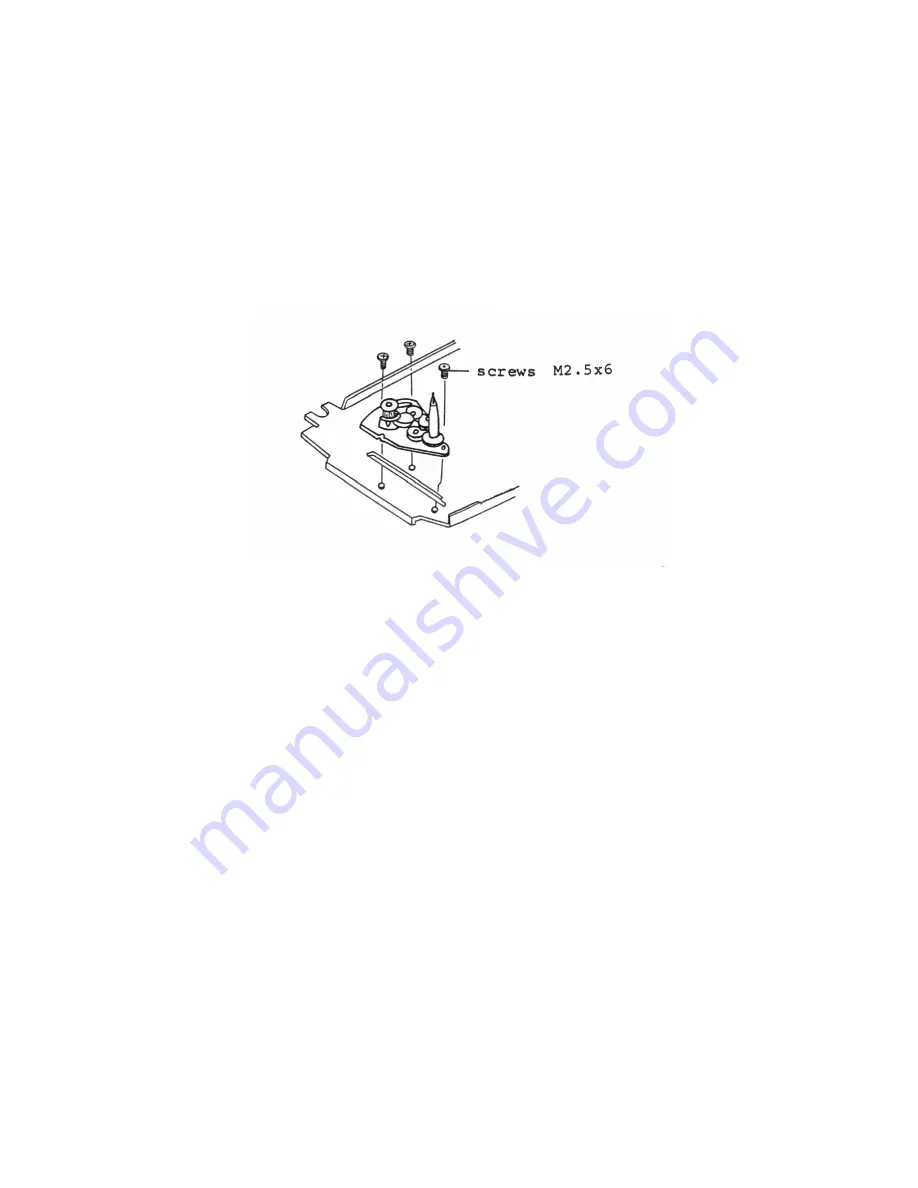

1) Remove three screws which fix the Ribbon Gear

Assy on the chassis as M2.5 x 6

2) Take out the synchronous belt from Ribbon Gear

Ass'y

3) In Case of Assembling, Do revese way of 2), 1)

But, Don't fix three screw completely, keep a

little bit loose for adjustment of tension of

synchronous Belt

2-2 Adjustment and Lubrication

2-2-1 Lubrication

•

Lubrication for Ribbon Gear Ass'y shuld be done

before assembling on the chassis.

•

Lubricate the grease (Beacon 325) to the

meshing part of the gears.

•

After lubricate, check the gears rotate smoothly

and no eccentricaly.

2-2-2 Adjustment of Tension of Synchronous Belt

• Move the Printer Head to the right end

print Head

-39-

Summary of Contents for XMM801

Page 1: ......

Page 2: ...SERVICE MANUAL PERIPHERAL PRINTER XMM 801...

Page 6: ...Figure 3 Internal Structure 2...

Page 11: ...8 XMM801 Timing chart at Power ON Figure 12 Timing Chart 7...

Page 14: ...Figure 18 Circuit Diagram 10...

Page 15: ...Figure 19 Parts Layout and Pattern Schematic 11...

Page 16: ...Figure 19 cont Parts Layout and Pattern Schematic 11a...

Page 18: ...5 Electric Circuit for Printer Mechanism Figure 22 Connection Diagram 13...

Page 20: ...Figure 23 TROUBLE 1 PRINTER IS TOTALLY OUT OF WORK 15...

Page 21: ...Figure 24 TROUBLE 2 INCORRECT FUNCTION OF PRINTER MECHANISM 16...

Page 23: ...Figure 26 TROUBLE 4 FEED MOTOR IS NOT WORKING 18...

Page 39: ...34...

Page 40: ...35...

Page 41: ...36...