-22-

Your wood furnace is a high efficiency furnace and therefore requires little maintenance. It is important to

perform a visual inspection of the furnace every time it is emptied, in order to insure that no parts have been

damaged, in which case repairs must be performed immediately. Inspect and clean the chimney and connector

pipe periodically for creosote buildup or obstructions.

GASKET

It is recommended that you change the door gasket (which makes your furnace door air tight) once a year, in

order to insure good control over the combustion, maximum efficiency and security. To change the door gasket,

simply remove the damaged one. Carefully clean the available gasket groove, apply a high temperature silicone

sold for this purpose and install the new gasket. You may light up your furnace again approximately 24 hours after

having completed this operation. This unit’s feed door uses a 3/4” diameter rope gasket. This unit’s ash door uses

a 1/2” diameter rope gasket.

PAINT

Only clean your furnace with a dry soft cloth that will not harm the paint finish. If the paint becomes scratched or

damaged, it is possible to give your wood furnace a brand new look by repainting it with a 1200° F heat resistant

paint. For this purpose, simply scrub the surface to be repainted with fine sand paper, clean it properly, and apply

thin coats (2) of paint successively.

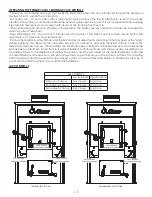

AIR TUBES

The air tubes assembled in this unit are designed to provide an accurate mix of secondary air to insure the

highest efficiency. Any damage or deterioration of these tubes may reduce the efficiency of combustion. The

air tubes are held in position by either screws or snap pins. Locate these to either side of the tube and remove to

allow the tube to be removed and replaced.

WARNING:

Never operate the furnace without a gasket or with a broken one. Damage to the furnace or

even house fire may result.

Maintenance

ATTENTION:

This wood heater needs periodic inspection and repair for proper operation. It is against federal

regulations to operate this wood heater in a manner inconsistent with operating instructions in this manual.

Summary of Contents for 1440E

Page 9: ...9 CENTRAL INSTALLATION Air Filter Replacement...

Page 27: ...Notes...