-

14

-

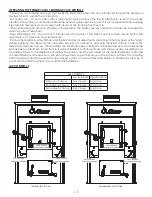

COMBUSTIBLE WALL CHIMNEY CONNECTOR PASS-THROUGHS

Method A. 12” (304.8 mm) Clearance to Combustible Wall

Member: Using a minimum thickness 3.5” (89 mm) brick

and a 5/8” (15.9 mm) minimum wall thickness clay liner,

construct a wall pass-through. The clay liner must conform

to ASTM C315 (Standard Specification for Clay Fire Linings)

or its equivalent. Keep a minimum of 12” (304.8 mm) of brick

masonry between the clay liner and wall combustibles. The

clay liner shall run from the brick masonry outer surface to

the inner surface of the chimney flue liner but not past the

inner surface. Firmly grout or cement the clay liner in place

to the chimney flue liner.

Method B. 9” (228.6 mm) Clearance to Combustible Wall

Member: Using a 6” (152.4 mm) inside diameter, listed,

factory-built Solid-Pak chimney section with insulation

of 1” (25.4 mm) or more, build a wall pass-through with a

minimum 9” (228.6 mm) air space between the outer wall of

the chimney length and wall combustibles. Use sheet metal

supports fastened securely to wall surfaces on all sides, to

maintain the 9” (228.6 mm) air space. When fastening

supports to chimney length, do not penetrate the chimney

liner (the inside wall of the Solid-Pak chimney). The inner end

of the Solid-Pak chimney section shall be flush with the inside

of the masonry chimney flue, and sealed with a non-water

soluble refractory cement. Use this cement to also seal to

the brick masonry penetration.

Method C. 6” (152.4 mm) Clearance to Combustible Wall

Member: Starting with a minimum 24 gauge (.024” [.61 mm])

6” (152.4 mm) metal chimney connector, and a minimum 24

gauge ventilated wall thimble which has two air channels of

1” (25.4 mm) each, construct a wall pass-through. There shall

be a minimum 6” (152.4) mm separation area containing

fiberglass insulation, from the outer surface of the wall thimble

to wall combustibles. Support the wall thimble, and cover

its opening with a 24-gauge minimum sheet metal support.

Maintain the 6” (152.4 mm) space. There should also be a

support sized to fit and hold the metal chimney connector.

See that the supports are fastened securely to wall surfaces

on all sides. Make sure fasteners used to secure the metal

chimney connector do not penetrate chimney flue liner.

Method D. 2” (50.8 mm) Clearance to Combustible Wall

Member: Start with a solid-pak listed factory built chimney

section at least 12” (304 mm) long, with insulation of 1” (25.4

mm) or more, and an inside diameter of 8” (2 inches [51 mm]

larger than the 6” [152.4 mm] chimney connector). Use this

as a pass-through for a minimum 24-gauge single wall steel

chimney connector. Keep solid-pak section concentric with

and spaced 1” (25.4 mm) off the chimney connector by

way of sheet metal support plates at both ends of chimney

section. Cover opening with and support chimney section

on both sides with 24 gauge minimum sheet metal supports.

See that the supports are fastened securely to wall surfaces

on all sides. Make sure fasteners used to secure chimney flue

do not penetrate flue liner.

NOTES:

Connectors to a masonry chimney, excepting method B, shall extend in one continuous section through the

wall pass-through system and the chimney wall, to but not past the inner flue liner face. A chimney connector

shall not pass through an attic or roof space, closet or similar concealed space, or a floor, or ceiling.

Summary of Contents for 1440E

Page 9: ...9 CENTRAL INSTALLATION Air Filter Replacement...

Page 27: ...Notes...