-21-

TAMPER WARNING

This wood heater has a manufacturer-set minimum low burn rate that must not be altered. It is against federal

regulations to alter this setting or otherwise operate this wood heater in a manner inconsistent with operating

instructions in this manual.

VISIBLE SMOKE

The amount of visible smoke being produced can be an effective method of determining how efficiently the

combustion process is taking place at the given settings. Visible smoke consist of unburned fuel and moisture

leaving your stove. Learn to adjust the air settings of your specific unit to produce the smallest amount of visible

smoke. Wood that has not been seasoned properly and has a high wood moisture content will produce excess

visible smoke and burn poorly. Use the included moisture meter to insure your wood has a 20% or less moisture

content.

EFFICIENCY

Efficiencies can be based on either the lower heating value (LHV) or the higher heating value (HHV) of the fuel.

The lower heating value is when water leaves the combustion process as a vapor, in the case of wood stoves the

moisture in the wood being burned leaves the stove as a vapor. The higher heating value is when water leaves

the combustion process completely condensed. In the case of wood stoves this would assume the exhaust gases

are room temperature when leaving the system, and therefore calculations using this heating value consider

the heat going up the chimney as lost energy. Therefore, efficiency calculated using the lower heating value of

wood will be higher than efficiency calculated using the higher heating value. In the United States all wood stove

efficiencies should be calculated using the higher heating value. The best way to achieve optimum efficiencies

is to learn the burn characteristic of you appliance and burn well-seasoned wood. Higher burn rates are not

always the best heating burn rates; after a good fire is established a lower burn rate may be a better option for

efficient heating. A lower burn rate slows the flow of usable heat out of the home through the chimney, and it

also consumes less wood.

SMOKE AND CO MONITORS

Burning wood naturally produces smoke and carbon monoxide(CO) emissions. CO is a poisonous gas when

exposed to elevated concentrations for extended periods of time. While the modern combustion systems in

heaters drastically reduce the amount of CO emitted out the chimney, exposure to the gases in closed or confined

areas can be dangerous. Make sure you stove gaskets and chimney joints are in good working order and sealing

properly to ensure unintended exposure. It is recommended that you use both smoke and CO monitors in areas

having the potential to generate CO.

OVER FIRING

Attempts to achieve heat output rates that exceed heater design specifications can result in permanent

damage to the heater

POWER FAILURE INSTRUCTIONS

DO NOT add additional fuel after a power failure, remove all air filters and reduce combustion air to a minimum.

Observe furnace closely until power is restored.

OPERATIONAL TIPS

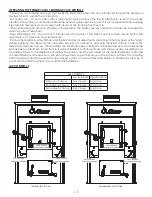

Operational Tips for Good, Efficient, and Clean Combustion

• Get the appliance hot and establish a good coal bed before adjusting to a low burn rate (this may take 30

minutes or more depending on your wood), for an optimal low burn rate, once there is a well established

fire in the furnace, close the damper on the door, and the rear pilot air damper completely, and open the

secondary air damper to its maximum setting

• Use smaller pieces of wood during start-up and a high burn rate to increase the stove temperature

• Be considerate of the environment and only burn dry wood

• Burn small, intense fires instead of large, slow burning fires when possible

• Learn your appliance’s operating characteristics to obtain optimum performance

• Burning unseasoned wet wood only hurts your stoves efficiency and leads to accelerated creosote buildup

in your chimney.

CAUTIONS:

• Ashes could contain hot embers even after two days without operating the furnace.

• The ash pan can become very hot. Wear gloves to prevent injury.

• Never burn the furnace with the ash trap open. This would result in over firing the furnace. Damage to the

furnace and even house fire may result.

Summary of Contents for 1440E

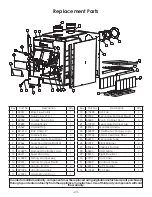

Page 9: ...9 CENTRAL INSTALLATION Air Filter Replacement...

Page 27: ...Notes...