4.5 - SINGLE ACTION PID CONTROL (1.rEG)

All the parameters referring to PID control are contained in the

group

“

]

rEG”.

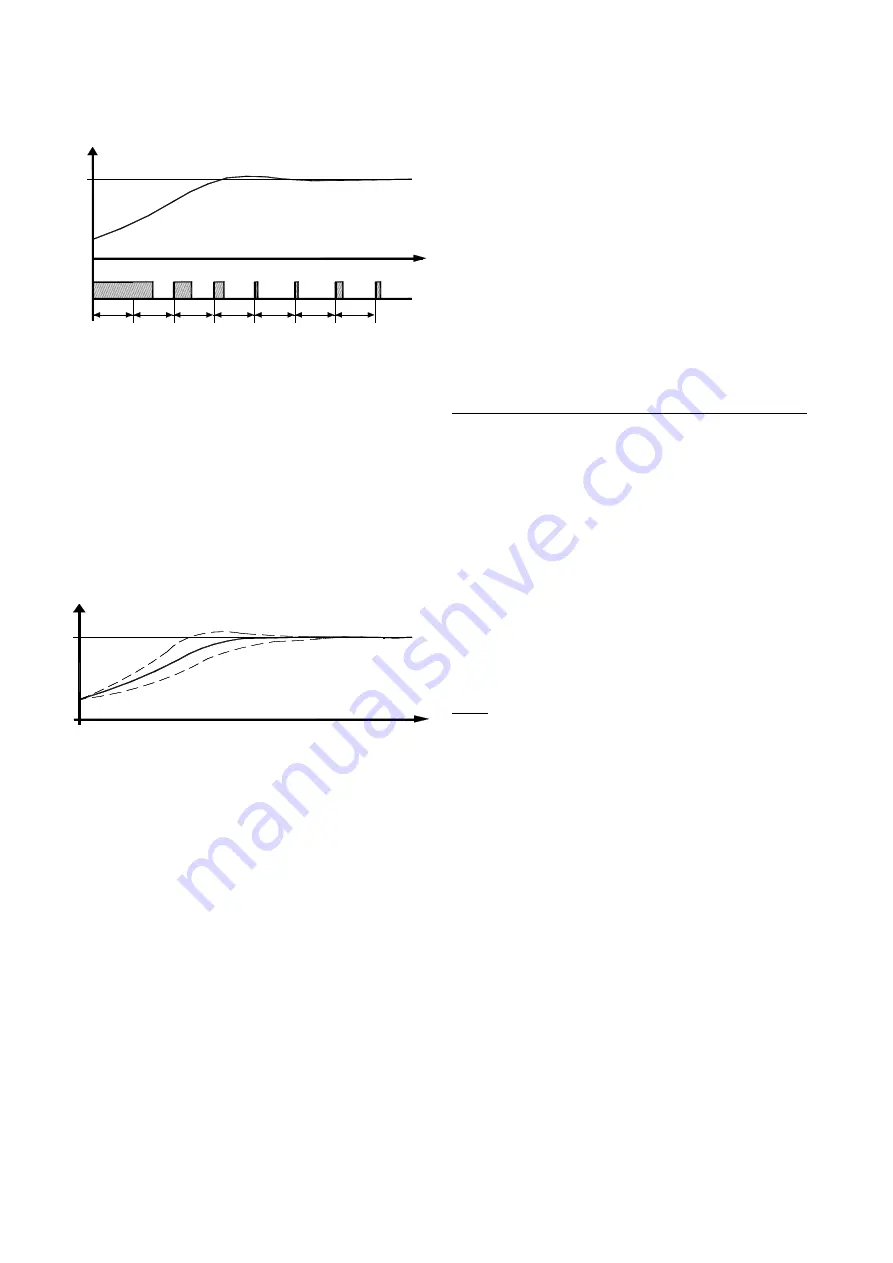

The Single Action PID control can be obtained by programming

par.

"Cont"

= Pid and works on the output 1.rEG depending on the

Set Point

“SP1”

, on the functioning mode

"Func”

and on the

instrument’s PID algorithm.

0 N

t c r 1

1 . r E G

( H E a t )

S P 1

P V

t c r 1

o f f

t c r 1

t c r 1

t c r 1

t c r 1

0 N

o f f

o f f

0 N

o f f

o f f

0 N

0 N

t c r 1

o f f

0 N

0 N

t i m e

O U T

In order to obtain good stability of the process variable, in the event

of fast processes, the cycle time “tcr1” has to have a low value with

a very frequent intervention of the control output.

In this case use of a solid state relay (SSR) is recommended for

driving the actuator.

The Single Action PID control algorithm foresees the setting of the

following parameters :

"Pb"

- Proportional Band

"tcr1"

- Cycle time of the output 1.rEG

"Int"

- Integral Time

"rS"

- Manual Reset (if “Int =0 only)

"dEr"

- Derivative Time

“FuOC” -

Fuzzy Overshoot Control

This last parameter allows the variable overshoots at the start up of

the process or at the changing of the Set Point to be avoided.

Please remember that a low value on this parameter reduces the

overshoot while a high value increase it.

2

1

3

S P 1

P V

t i m e

1: Value “FuOC” OK

2: Value “FuOC” too high

3: Value “FuOC” too low

4.6 - DOUBLE ACTION PID CONTROL (1.rEG - 2.rEG)

All the parameters referring to PID control are contained in the

group

“

]

rEG”.

The Double Action PID control is used to control plants where there

is an element which causes a positive increase (ex. Heating) and an

element which causes a negative increase (ex. Cooling).

This type of control can be obtained when 2 outputs are

programmed respectively as 1.rEG and 2.rEG and the par.

“Cont”

= Pid.

The element causing a positive increase has to be connected to the

output programmed as 1.rEG while the element causing a negative

increase has to be connected to the output programmed as 2.rEG.

The Double Action PID control works on the outputs 1.rEG and

2.rEG depending on the Set Point

“SP1”

and on the instrument’s

PID algorithm.

In order to obtain good stability of the process variable, in case of

fast processes, the cycle times “tcr1” and “tcr2” have to have a low

value with a very frequent intervention of the control outputs.

In this case use of solid state relays (SSR) to drive the actuators is

recommended.

The Double Action PID control algorithm needs the programming of

the following parameters :

"Pb"

- Proportional Band

"tcr1"

- Cycle time of the output 1.rEG

“tcr 2”

- Cycle time of the output 2.rEG

"Int"

- Integral Time

"rS"

- Manual Reset (if “Int =0 only)

"dEr"

- Derivative Time

“FuOC” -

Fuzzy Overshoot Control

"Prat"

- Power Ratio or relation between power of the element

controlled by output 2.rEG and power of the element controlled by

output 1.rEG.

4.7 - AUTOTUNING FUNCTION

All the parameters referring to the AUTOTUNING function are

contained in the group

“

]

rEG”.

The

AUTO-TUNING

function (

FAST

or

OSCILLATING

type)

permits the calculation of the PID parameters by means of a tuning

cycle and, at the end of this operation, the parameters are stored

into the instrument’s memory and remain constant during control.

Both modes calculate the following parameters automatically:

“Pb”

- Proportional band

“tcr1”

- output cycle time

“Int”

- integral time

“dEr”

- derivative time

“FuOC” -

Fuzzy Overshoot Control

To activate the AUTOTUNING function, proceed as follows:

1) Set the Set point

“SP1"

desired.

2) Set the parameter

"Cont" =Pid.

3) Program par. "Func" according to the process to be controlled

through output 1.rEG.

4) Program an output as 2.rEG if the instrument controls a plant with

double action

5) Set the parameter

"Auto"

as:

= 1

- if the autotuning is to be started automatically each time the

instrument is turned on.

= 2

- if the autotuning is to be started automatically when the

instrument is turned on the next time and, once tuning has been

completed, the parameter “Auto"=OFF is set automatically.

= 3

- if autotuning is started up manually, by the key U

= 4

- if autotuning is to be started automatically each time the

regulation set is changed.

6) Set the parameter

"SEL.A"

as:

= FASt

- for FAST mode autotuning

= OSC

- for OSCILLATING mode autotuning

Note: the Autotuning Fast type is particularly rapid and has no effect

on the control as it calculates the parameters during the Set Point

reaching phase.

In order to correctly perform the Autotuning Fast type it’s necessary

that at the start of the cycle there is a certain difference between the

process and the Set Point and for this reason the instrument

activates the Autotuning Fast type only when :

- For “Auto” = 1 or 2: the process value is lower (with “Func” =HEAt)

than [SP- |SP/2|] or higher (with “Func” =CooL) than [SP+ |SP/2|].

- For “Auto” = 3 or 4 : the process value is lower (with “Func”

=HEAt) than [SP- |SP/5|] or higher (with “Func” =CooL) than [SP+

|SP/5|].

The Autotuning Fast type is not advisable when the Set Point is next

to the initial reading or when the measured variable changes

irregularly during the tuning cycle (for reasons due to the process

the variable goes up or down).

In this cases we advice the Autotuning oscillatory type that activates

some ON-OFF control cycles permitting the oscillation of the

process value around the Se Point value and afterward the control

swap to the PID type with those values calculated by the

Autotuning.

7) Exit the parameter programming mode.

8) Connect the instrument to the controlled system.

9) Start up autotuning turning off and on the machine if “Auto" = 1 or

2, pressing the key U if “Auto" = 3, or by varying the Set value if

“Auto" = 4.

At this point, the Autotuning function is started up and is marked by

the turning on of the led AT/ST.

Ascon Tecnologic - TLK 72 B - OPERATING INSTRUCTIONS -

PAG. 5