ASCO 3ATS, 3ADTS, 3NTS, 3NDTS

Installation Manual

Page 4

ASCO Power Technologies

381333-404 B

LOWER SHAFT

Normal source

contacts

UP closes

the contacts

DOWN opens

the contacts

hub

hub

frame

handle

UPPER SHAFT

Emergency contacts

UP opens

The contacts

DOWN closes

The contacts

Figure 6. Maintenance handle operation on 3ADTS & 3NDTS

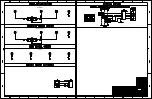

Table B.

3ADTS &

3NDTS

Table B. 3ADTS & 3NDTS Maintenance Handle positions.

ALL POWER MUST BE OFF !

Transfer Switch Position

Interlocked Shafts

Link between contact shafts prevents

closing both N & E contacts

Maintenance

Handle

Shaft Indicators

Normal

E = O

upper contacts open

N = C

lower contacts closed

Load

Disconnected

E = O

upper contacts open

N = O

lower contacts open

Emergency

E = O

upper contacts closed

N = C

lower contacts open

Note: The hub and contact shaft turn in opposite directions through a cam follower mechanism.

Note: If Normal and Emergency connections are reversed, this operation is also reversed.

up

down

up

up

down

down

hub

hub

contact shafts

Summary of Contents for 3ADTS

Page 2: ...ASCO ASCO ...

Page 3: ...ASCO ...

Page 4: ...ASCO ...

Page 5: ...ASCO ...

Page 6: ...ASCO ...

Page 7: ...ASCO ...