Installation Manual

ASCO 3ATS, 3ADTS, 3NTS, 3NDTS

381333-404 B

ASCO Power Technologies

Page 3

left side of

transfer switch

maintenance

handle

clip

contact shaft hub

Figure 4. Maintenance handle on 3ATS & 3NTS

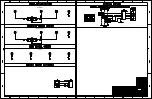

left side of

transfer switch

maintenance

handle

clip

Emergency source

contact shaft hub

Hubs shown with

Emergency source

contacts open and

Normal source contacts

closed. See Table B

on page 4.

Normal source

contact shaft hub

Figure 5. Maintenance handle on 3ADTS & 3NDTS

hub

frame

handle

UP closes the

Normal source

contacts (lower)

DOWN closes the

Emergency source

contacts (upper)

Functional Test

The functional test consists of three checks: manual

operation, voltage checks, and electrical operation.

Do these checks in the order presented to avoid

damaging the transfer switch.

1 – Manual Operation

A maintenance handle is provided on the transfer switch for

maintenance purposes only. Manual operation of the transfer

switch should be checked before it is energized (operated

electrically).

Do not manually operate the transfer switch until

both power sources are disconnected: open both

circuit breakers.

1.

After deenergizing both power sources, open the enclosure

door. Locate and remove the maintenance handle from the

clip on the left side of the transfer switch. See Figures 3, 4,

5, & 6. See Figure 2 for the contact position indicators.

2.

Install the handle into the hole in the molded hub. Move

the handle up or down as shown to manually operate the

transfer switch. It should operate smoothly without any

binding. If it does not, check for shipping damage or

construction debris.

3.

3ADTS and 3NDTS have two contact shaft hubs. See

Figures 5 and 6 and Table B.

4.

Return the transfer switch to the Normal position.

Note: If Normal and Emergency connections are reversed this

operation

is also

reversed.

Figure 3. Maintenance handle operation

on 3ATS & 3NTS.

Summary of Contents for 3ADTS

Page 2: ...ASCO ASCO ...

Page 3: ...ASCO ...

Page 4: ...ASCO ...

Page 5: ...ASCO ...

Page 6: ...ASCO ...

Page 7: ...ASCO ...