Subject to change · 40719700 · 1217 · EN

Page 18

www.argo-hytos.com

10.1 Maintenance

10.2 Maintenance overview

Except from the fi lter element and the suction strainer, the fi lter unit is maintenance-free.

Maintenance work

Order No.

Maintenance interval

Checking / changing the fi lter element

V3.0510-53 (5 µm)

V3.0510-56 (10 µm)

V3.0510-58 (16 µm)

Once the clogging indicator changes to the

red range at a permissible viscosity

Checking / changing the suction strainer

40442600

Quarterly or with corresponding

problems (lower volume fl ow with clean fi lter

element, too loud noise level).

Table 6: Maintenance overview

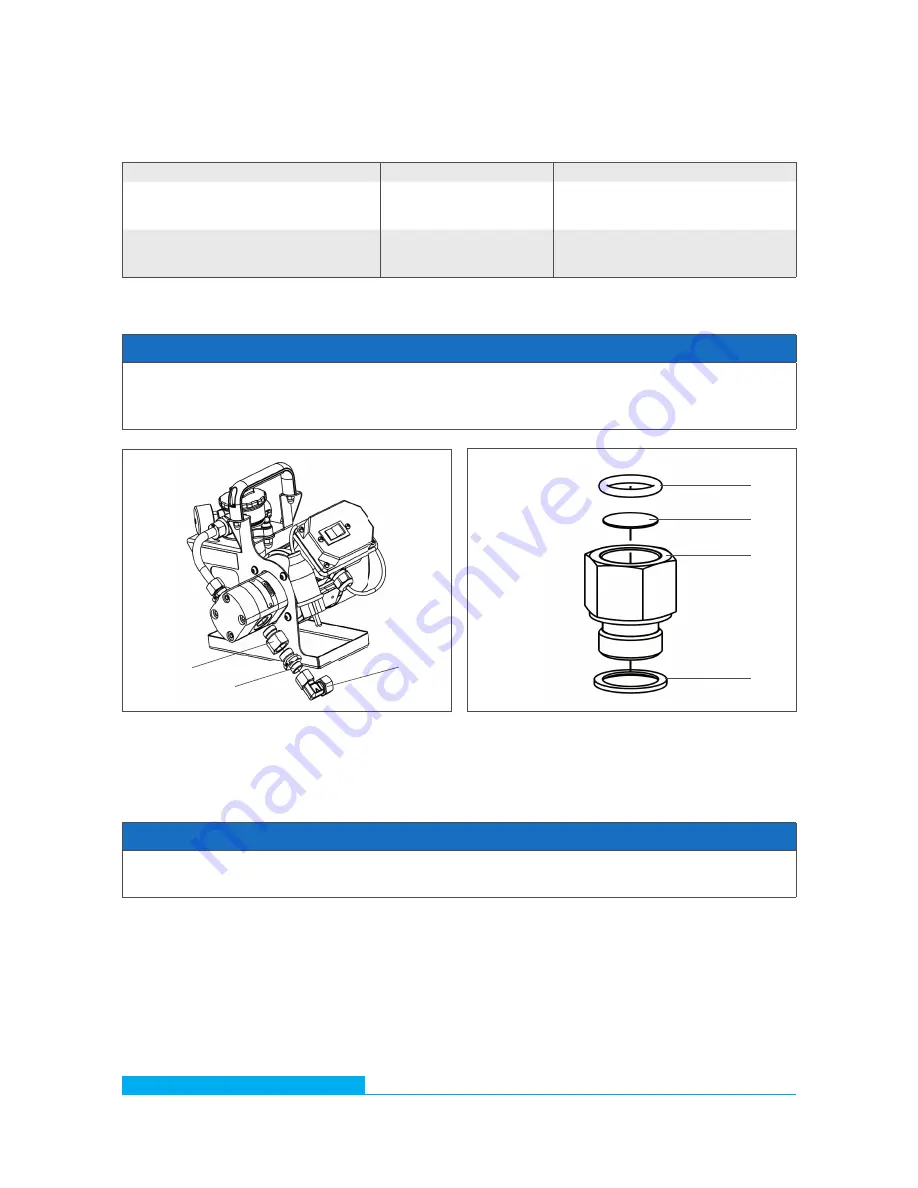

10.2.1 Cleaning / replacing the suction strainer

1. Loosen and unscrew the elbow fi tting (1).

2. Loosen and unscrew the straight nipple (2).

3. Unscrew the suction strainer set (3) from the inlet port of the pump.

4. Clean the suction strainer using cleaning agent (benzine or diesel fuel).

NOTE

›

In case of damage, replace the metal mesh, sealing, and / or O-ring installed inside of the strainer housing - Figure 7.

(Order No. - see spare part list).

5. Screw the suction strainer set (3) into the pump inlet port.

6. Screw the straight nipple (2).

7. Screw the elbow fi tting (1)

Fig. 9: Changing the suction strainer

Fig. 10: Components of suction strainer:

1

2

3

NOTE

Damage to the fi lter unit by missing or defective suction strainer.

Property damage

›

The suction strainer must be regularly checked, cleaned and replaced if necessary, according to the maintenance intervals.

O-ring

metal mesh

housing

fl at sealing

type ED