Arconic Inc. (NYSE: ARNC) creates breakthrough products that

shape industries. Working in close partnership with our customers,

we solve complex engineering challenges to transform the way

we fly, drive, build and power.

Through the ingenuity of our people and cutting-edge advanced

manufacturing, we deliver these products at a quality and

efficiency that ensures customer success and shareholder value.

CERTIFIED

MANAGEMENT

SYSTEM

ISO 9001-2015

ISO 14001-2015

© 2018 Huck International, Inc.

Arconic Fastening Systems

Kingston Operations

1 Corporate Drive, Kingston, NY 12401

Tel: 800-431-3091 • Fax: 845-334-7333

www.afshuck.net/us

InDUSTRIAl nORTH AMERICA

Kingston Operations

1 Corporate Drive

Kingston, NY 12401

Tel: +1-800-278-4825

Fax: +1-845-334-7333

Tracy Operations (IDG)

1925 North MacArthur Drive

Tracy, CA 95376

Tel: +1-800-826-2884

Fax: +1-800-573-2645

Waco Operations

PO Box 8117

8001 Imperial Drive

Waco, TX 76714-8117

Tel: +1-800-388-4825

Fax: +1-800-798-4825

InDUSTRIAl GlOBAl

Kolkata Operations

Unit No. 28, 2nd Floor,

55/1, Chowringhee Road,

Kolkata 700071, West Bengal, India

Tel: +91-33-40699170

Tel: +91-33-40699180

Fax +91-33-40699184

Melbourne Operations

1508 Centre Road

Clayton, Victoria

Australia 3168

Tel: +613-8545-3333

Fax: +613-8545-3390

São Paulo Operations

Rodovia Anhanguera, s/n, KM 17

Parque São Domingos - Complexo

Anhanguera - Galpão 1 Seção III

(Módulo III) Box 11

CEP 05112-000 São Paulo – SP Brazil

Tel: +55-11-3583-7061

Suzhou Operations

58 Yinsheng Road,

SIP Suzhou, Jiangsu

215126 China

Tel: +86-512-62863800-8888

Telford Operations

Unit C, Stafford Park 7

Telford, Shropshire

England TF3 3BQ

Tel: +44-(0)-1952-290011

Fax: +44-(0)-1952-207701

Tokyo Operations

(Japan and Korea)

1013 Hibiya U-1 Bldg.

Uchisaiwai-cho 1-1-7

Chiyoda-ku, Tokyo

100-0011 Japan

Tel: +81-3-3539-6594

Fax: +81-3-3539-6585

AEROSPACE nORTH AMERICA

Kingston Operations

1 Corporate Drive

Kingston, NY 12401

Tel: +1-800-278-4825

Fax: +1-845-334-7333

Simi Valley Operations

3990A Heritage Oak Court

Simi Valley, CA 93063

Tel: +1-805-527-3600

Fax: +1-805-527-0900

www.afs-simivalley.com

AEROSPACE GlOBAl

Aichach Operations

Robert-Bosch Str. 4

Aichach 86551

Germany

Tel: +49-8251-8757-0

Cergy Operations

15 Rue du Petit Albi

F-95611 Cergy Pontoise

France

Tel: +33-1-34-33-98-00

Fax: +33-1-34-33-97-77

Hong Kong Operations

27th Floor, 88 Hing Fat Street

Causeway Bay

Hong Kong, China

Tel: +852-2864-2012

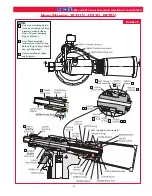

Arconic Fastening Systems Tooling Support locations

Huck provides technical assistance

regarding the use and application of

Huck fasteners and tooling.

NOTICE:

The

information contained in this publication

is only for general guidance with regard

to properties of the products shown and/

or the means for selecting such products,

and is not intended to create any warranty,

express, implied, or statutory; all warranties are contained

only in Huck’s written quotations, acknowledgments,

and/or purchase orders. It is recommended that the

user secure specific, up-to-date data and information

regarding each application and/or use of such products.