9

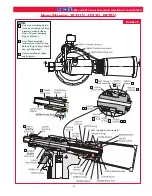

2022 and ERT9 series Pneudraulic Installation Tools (HK1021)

Disassembly

GEnERAl

This procedure is for complete disassembly of the

tool. Disassemble only those components necessary

to replace damaged O-rings, Quad-rings, Back-

up rings, and worn or damaged components. For

component identification, see Figures 1, 2, & 14.

1. Disconnect the tool from the air source.

2. Unscrew the retaining nut (2022 models only)

and remove the nose assembly. (Follow the

instructions on the

Nose Assembly Data Sheet

.)

3. Unscrew the bleed plug from top of the handle/

head. Turn over the tool and drain the fluid into

a container. (The tool can be cycled to clear

more completely.) Discard the fluid. (Figure 1)

4. Models 2022 & 2022l

: Pull the pintail deflector

off the end cap.

Models 2022V, 2022lV, & ERT9V: See

Pintail

Bottle/Vacuum System Disassembly

.

5. Remove the throttle arm pivot screw and lift out

the throttle arm. Disconnect the ball end of the

cable assembly from it. Remove the spring from

the throttle valve. (Figure 14)

6. Secure the tool upside-down in a soft-jaw vise;

use a 1/8” hex key to remove three button-head

screws from the muffler end cap. Remove the

muffler end cap and bottom exhaust gasket, and

remove the muffler from the end cap. (Figure 2)

7. Tap down the cylinder head with a soft mallet

(to take pressure off the ring), and remove the

retaining ring.

8. Screw the button-head screws into cylinder

head; (Figure 2) carefully pry on screws to

remove head.

9. Pull on lock nut with vise-grips to remove the air

piston from cylinder. Remove the piston

Quad-

ring.

nOTE:

Do NOT disassemble

the air piston and

rod assembly

. If the locknut loosens, apply

Loctite

®

271-05 and tighten to 25–30 ft.-lbs.

10. Remove the bumper from the gland assembly.

Unscrew the gland assembly with a 1-3/8” socket

wrench and extension.

11. Remove the retaining ring from the gland, and

then pull out the spacer and Polyseal. Remove

the O-rings,

Quad-ring

, and Back-up ring. lift

the cylinder assembly from the handle/head.

(Figure 2)

12.

Turn over the tool and drain the fluid into a

container; discard the fluid. Remove the throttle

valve from the air cylinder, and remove the

O-rings. (Figure 2)

Figure 1

CONTAINER

(Discard Fluid)

111795

Retaining Nut

104293

Bleed

Plug Assembly

Remove the Bleed Plug Assembly,

turn the tool on its side, and

drain the hydraulic fluid.

504127

Button

Head Screw (4)

128792

Bottom Plate

507445

Retaining

Ring

126941-1

Gasket

115554-1

Muffler

O-ring

Timing Pin

125747

Cylinder Head

126221

Handle

Assembly

500871

Cylinder

Head O-ring

130729

Piston

505420

Locknut

116408

Bumper

125753

Piston

Rod

125150

End Cap

124210

Pintail

Deflector

500903

O-ring

125733 Cylinder

Assy.

(Figure 14)

(Figure 14)

125742 Gland

Assy.

Figure 2

WARnInG: Disconnect the air hose from the

tool before performing any maintenance.

Serious personal injury could result if the air

hose is connected.

CAUTIOn: Always use a soft-jaw vise to

avoid damaging the tool.

CAUTIOn: Take care to not scratch the

piston rod or cylinder when removing.