42

Front panel

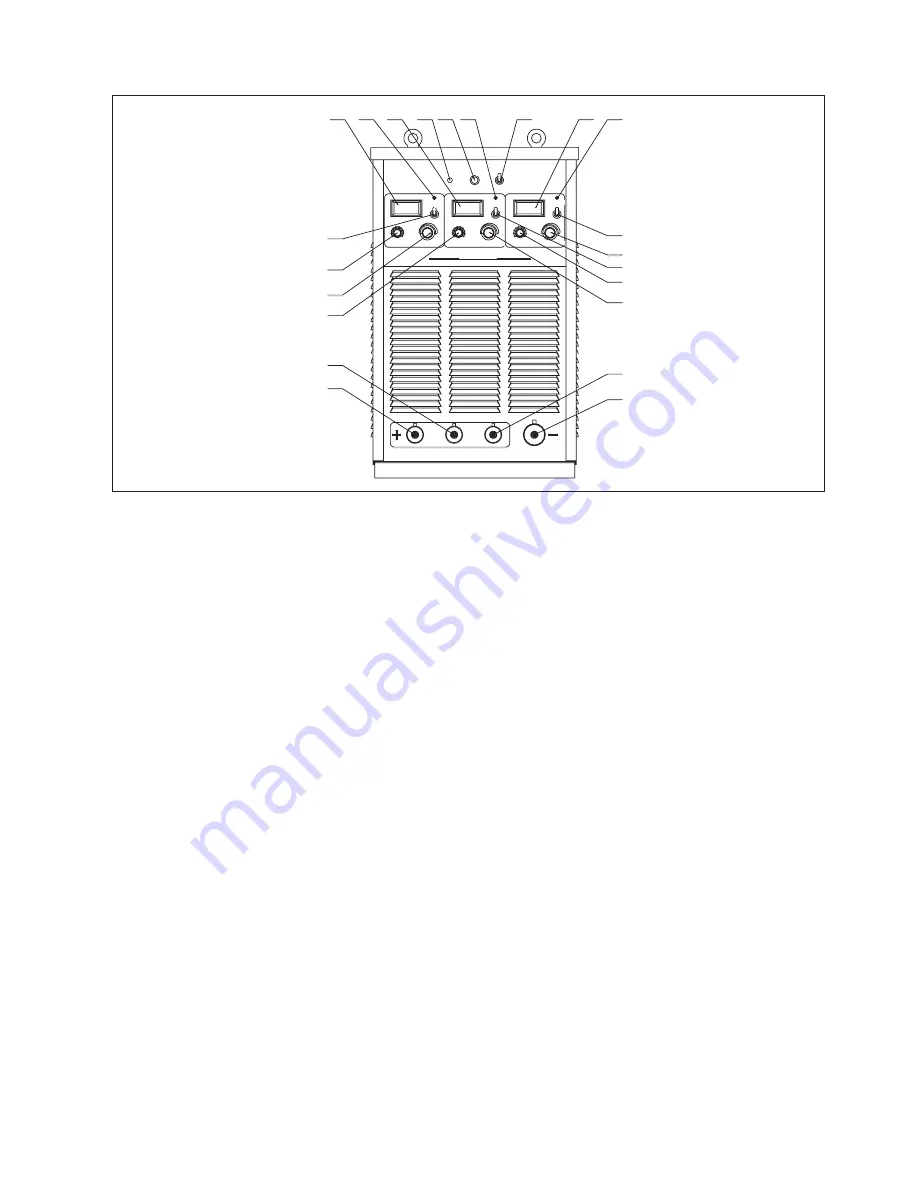

Fig. 7-3-1: Front panel

1-3.“Amp/Volt” displayer

When display mode switch indicates to “Amp”:

- LCD displays preset current value, Min. current is 20A;

- LCD displays real welding current during working.

When display mode switch indicates to “Volt”, LCD displays voltage between output terminals of welding machine.

4-6.Protection indicator

Welding machine will automatically stop working when it is overheat, and the indicator will light up.

7.Default phase indicator

Indicator indicates when power source is default phase.

8.Fan indicator

Indicator indicates whether Fan is on or not.

9.Fan control

Choose Fan on “ON” or “OFF” position. When choose ON, fan runs, choose off, fan stops running. Keep fan running for 20

minutes after finishing welding.

10-12.Amp/Volt displayer mode selection switch

13-15. Start current regulation knob

It is used to adjust arc starting current under SMAW mode.

Before start arc, work piece is on cold state, increase arc start current so as to improve heat input, which makes the arc start

easier.

16-18. “Welding current” regulation knob

It is used to adjust welding current on panel control mode.

Preset proper welding current according to work piece thickness, groove shapes, welding position, wire diameter, etc.

Welding current decides welding seam depth and wire molten rates.

19-21. Positive output terminal (+)

Connect with electrode holder via welding cable.

22. Negative output terminal (-)

Connect with work piece via ground cable.

Ⅱ

I

Ⅱ

Ⅲ

I

Ⅲ

A

A

A

1

2

3

4

5

6

7

8

9

10

A

/

V

A

/

V

1

2

3

4

5

6

7

8

9

10

2

1

3

4

5

6

7

8

9

10

A

/

V

V

V

V

Inverter DCAr c We lding Ma c hine

ARC400

-

3T

START CURR E NT

START C U RRENT

Default p h ase

WELDING CU RRENT

WELDING C U RRENT

START CUR R ENT

WELDING CURR E NT

Protection

Protection

Protection

OFF

ON

FAN CO NTROL

FAN I N DICATOR

1

22

21

20

19

18

11

17

16

15

14

13

12

10

9

8

5

4

2

7

6

3