6

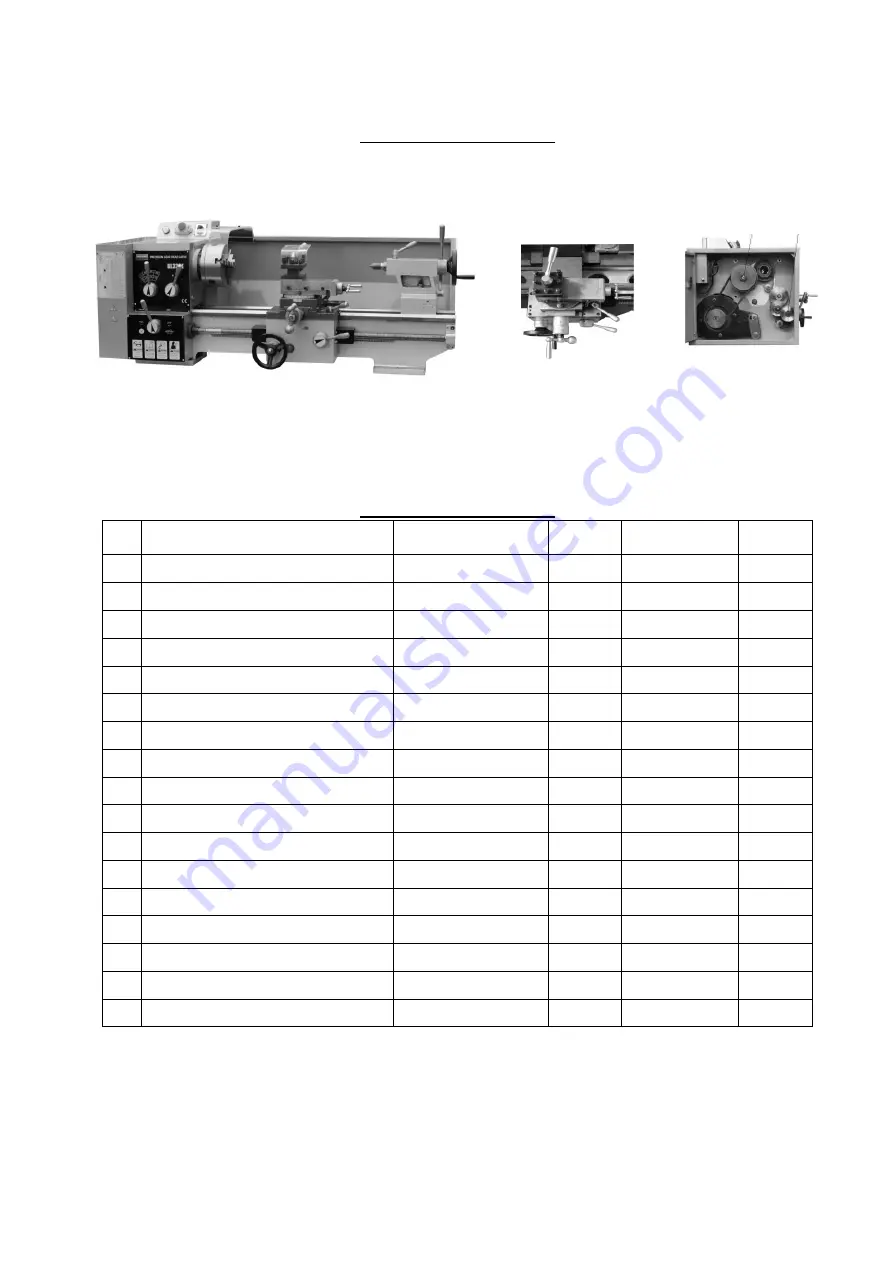

Lubrication Positions

Fig 4. Lubrication positions drawing.

Refer to the Lubrication chart on the following page in order to properly lubricate and maintain your

Lathe. Proper lubrication of any tools, especially Metal Lathes should not be ignored.

Lubrication Positions

No. Lubrication Position

Located part

Located Lubrication Oil

Period

1

Gears. bush bearing

Left trestle

Gun

Machine oil

0ne year

2

Spindle bearing

Lathe head

Greasing Grease

1/year

3

Thrust bull bearing

Left trestle

Greasing Grease

1/year

4

Slide way, lead screw, guide surface

Apron parts

Gun

Machine oil

2/days

5

Gears, racks

Apron parts

Greasing Grease

1month

6

Tool post lead screw, guide surface

Tool carriage

Gun

Machine oil

2/days

7

Longitudinal lead screw

Lead screw

Gun

Machine oil

2/days

8

Lathe bed guide

Lathe bed

Gun

Machine oil

2/days

9

Tail stock sleeve

Tailstock

Gun

Machine oil

2/days

10

Tailstock lead screw bush bearing

Tailstock

Gun

Machine oil

2/days

11

Bearing pedestal

Lathe bed

Gun

Machine oil

2/days

12

Cross nut lead screw

Small carriage

Gun

Machine oil

2/days

13

Bearing bush

Small carriage

Gun

Machine oil

2/days

14

Thrust bearing

Lead screw pedestal

Greasing Grease

6/s year

15

Tailstock lead screw bush bearing

Tailstock

Gun

Machine oil

2/days

16

Change gear shaft

Compound box

Gun

Machine oil

2/s year

17

Bearing

Input pulley

Greasing Grease

6/s year

Notes:

1. Recommend to fill 3# Ca grease 20# machine oil

2. The parts lubricated by grease should be cleaned and the machine oil in feed box should

be changed and renewed up to the center line of the oil indicator regularly.

Summary of Contents for BL330E

Page 1: ......

Page 10: ...10 ...

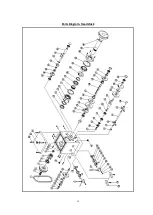

Page 14: ...14 Parts Diagram Headstock ...

Page 16: ...16 Parts Diagram Trestle ...

Page 18: ...18 Parts Diagram Bed ...

Page 20: ...20 Parts Diagram Apron ...

Page 22: ...22 Parts Diagram Tailstock ...