17

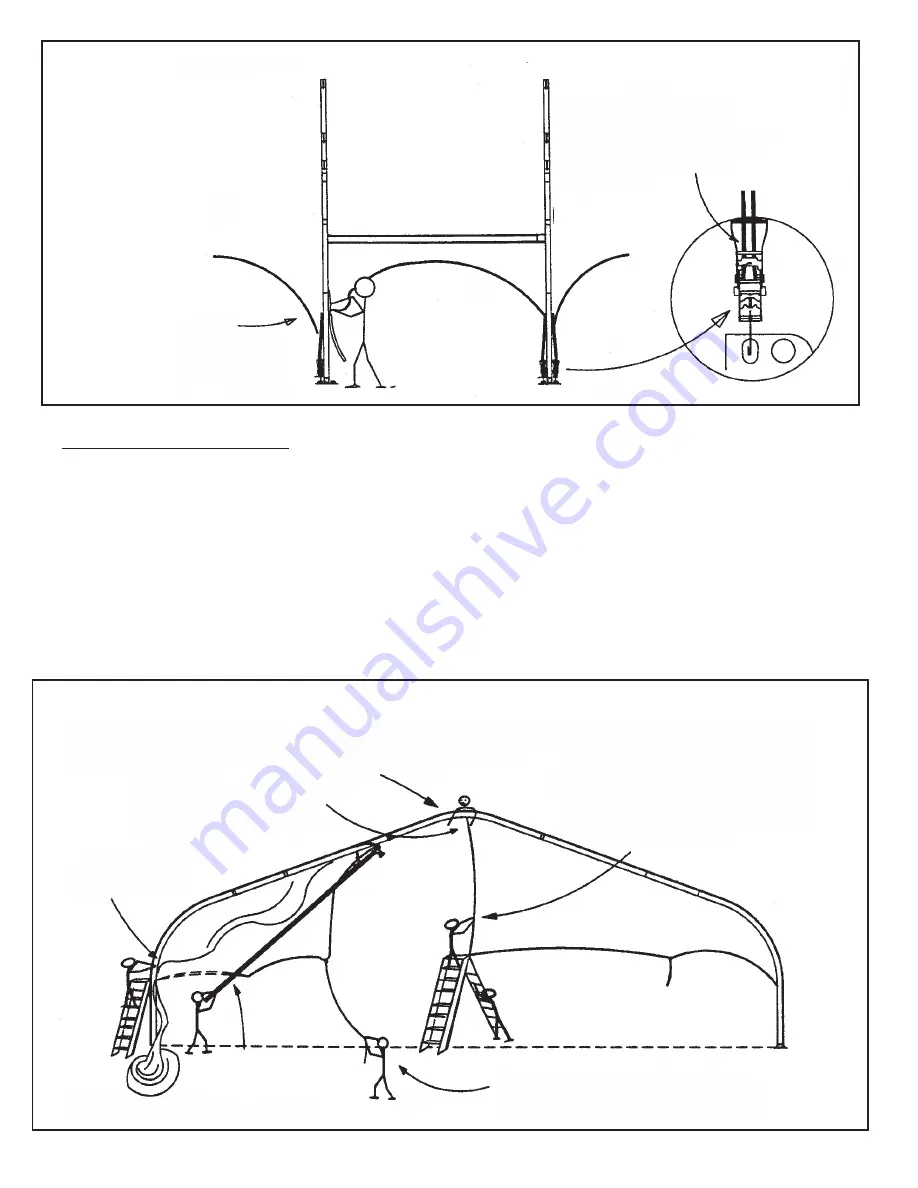

Tensioning of Middle Panels: (See Above)

1. Tuck the fabric tails of each panel downward into the beam channel flare until all

middle panel kedar rests within the outer beam channel.

2. Install (2) fabric tensioning winches with hooks into each baseplate, as shown.

3. Insert the tension webs of each middle panel through the slot in the spindle of each

fabric winch and pull all surplus webbing through the winch.

4. Crank the handle of the winch so that the webbing is wrapped around the spindle.

Install Gabled End Fabric Panel (See Top of Page 18)

5. Coordinate the tensioning of all four corners of each middle panel, so that tensioning

is equalized and wrinkles are avoided. Metal pull rings should be equal distance

above the baseplate at all four corners of the panel.

Insert web tail

through spindle.

Ratchet handle up

& down to tension

fabric

Tuck kedar tail

downward into

outer beam channel

Tensioning of Middle Panels

Using a safety line tied off to the frame system, a worker

lays on last middle panel and engages caribiner to join the 2

halves of the gabled end and lace down the first 3 or 4 loops.

2 piece end is joined by caribiners at

top and bottom of lace line.

Feed into Liner

Channel

Lacing is completed from ladder at

ground level. (Minimum 12’ ladder see

step #5, next page. For full lace, use

14’ ladder or taller.

In a strong breeze, attach safety rope to tail of end

panel to avoid “wind-whip” that could damage fabric

or injure workers.

Install Gabled End Fabric Panel (See top of page 18)

Push Purlin tool into metal

ring of fabric to slide panel

up and into Liner channel