Installation and Upgrading

17

NI-2100, NI-3100, NI-4100 Hardware Reference Guide

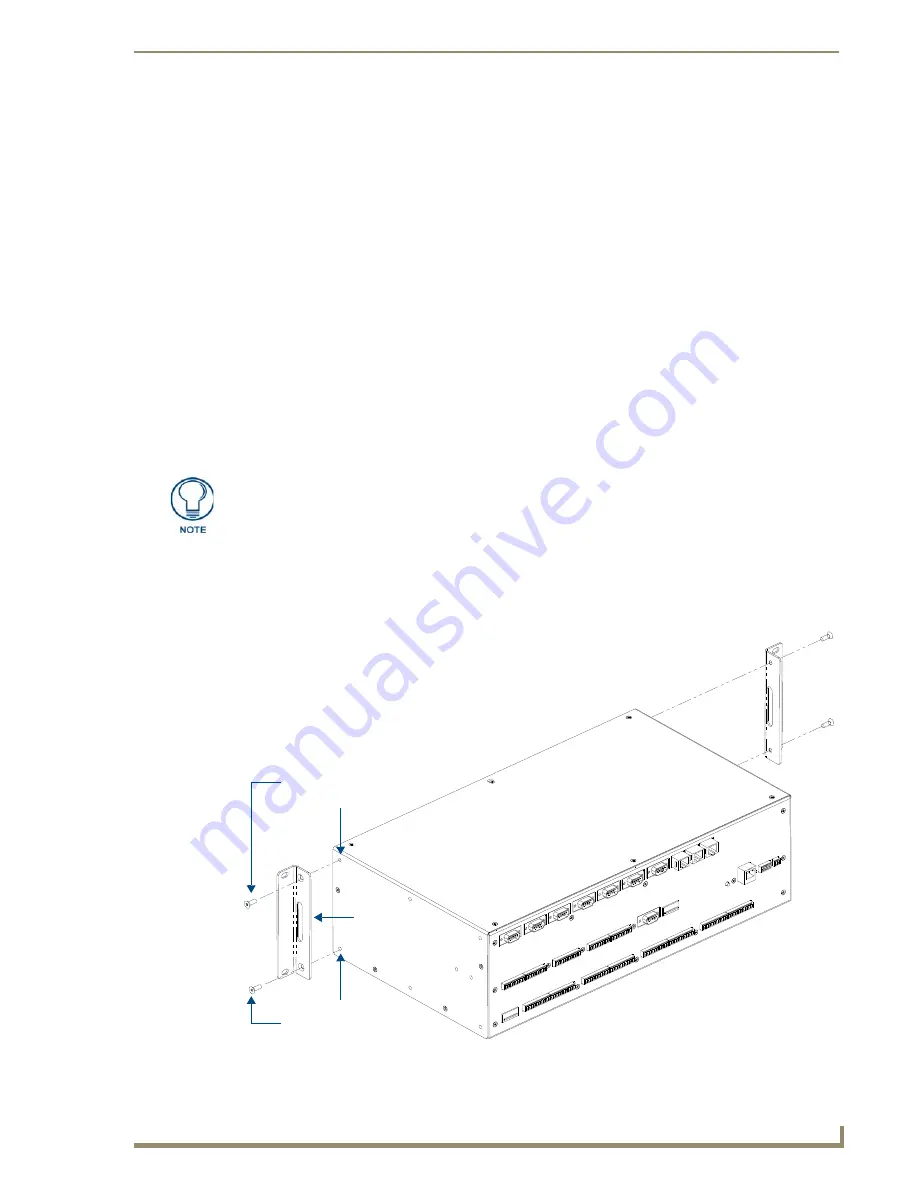

Installing Into An Equipment Rack

Use the rack-mounting brackets (supplied) for equipment rack installations.

Remove the mounting brackets for flat surface installations.

Rack Mount Safety Instructions

If installed in a closed or multi-unit rack assembly, the operating ambient temperature of the rack

environment may be greater than room ambient. Therefore, consideration should be given to

installing the equipment in an environment compatible with the maximum ambient temperature

50°C.

Installation of the equipment in a rack should be such that the amount of air flow required for safe

operation of the equipment is not compromised.

Mounting of the equipment in the rack should be such that a hazardous condition is not achieved

due to uneven mechanical loading.

Consideration should be given to the connection of the equipment to the supply circuit and the

effect that overloading of the circuits might have on over current protection and supply wiring.

Appropriate consideration of equipment nameplate ratings should be used when addressing this

concern.

Reliable earthing of rack-mounted equipment should be maintained. Particular attention should be

given to supply connections other than direct connections to the branch circuit (e.g. use of power

strips).

1.

Discharge the static electricity from your body by touching a grounded object.

2.

Position and install the mounting brackets, as shown in FIG. 7, using the screws supplied with the unit.

The mounting brackets can be rotated to accommodate your mounting needs.

Before completing the install process, it is recommended that you complete any

firmware upgrade of the NetLinx Control Cards. This upgrade involves physically

cycling power to the unit and can become cumbersome if the unit is already installed

into a rack. Refer to the NI Series NetLinx Integrated Controllers WebConsole &

Programming Guide (available online at www.amx.com) for detailed instructions.

FIG. 7

Mounting Integrated Controller into an equipment rack

Install screws

Bracket

Rack Mounting Holes

Rack Mounting Holes

Install screws