Calibration Procedure for the Pressure Display Module

Setup:

Connect the display PCB to a well calibrated Sensor module in a working frame and

power supply.

The calibration of the pressure module requires the following equipment:

- Source of known pressure with a reliable gauge or pressure measuring instrument.

Procedure:

1

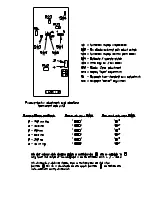

Set the jumper selections SW1, SW2, SW3 and SW5 according to the pressure

range to be calibrated.

2

Set the calibrate/operate switch (SW4) to the calibrate position.

3

Apply power to the module.

4

Disconnect the pressure sensor module and short terminals #1 and #4 of connector

J2 on the display module. Adjust R22 for zero numerical indication.

5

Reconnect the pressure sensor module and apply a known, measured pressure

(preferable at least 90% full scale) to the pressure transducer.

6

Adjust R25 for the appropriate numerical indication for the range and units of

display settings of SW1, SW2, SW3 and SW5. Repeat steps 4,5 and 6 until

satisfactory.

7

Apply an input for 50% of scale. Adjust R42 to place the bargraph display at

center.

8

Confirm that the decimal select jumper SW3 will turn on either the middle or

right hand decimal points.

9

Confirm that alarms are generated and that the "HI ALARM" and "LOW

ALARM" LED's flash and the "NORMAL" LED extinguishes, by changing the

pressure out of the safe area (+/- 20%), or by readjusting R42 to artificially move

the LED bar display.

10

Put the calibrate/operate switch (SW4) to the operate position.

The Pressure Display Module is factory calibrated for set points at 40 PSI (LOW)/60 PSI

(HIGH). If you wish to change the settings, you would adjust "R42" to move the whole

range up or down. DO NOT adjust "R22" and "R25", they are factory set at "0" and full

scale. Do not adjust the potentiometers on the sensor modules, they are also factory set at

"0" and full scale. To obtain a larger or smaller range you must change "SW2" and then

adjust "R6" to obtain the proper range. You would then adjust "R42" to obtain the desired

values.

Calibration Procedure for the Pressure Display Module

Setup:

Connect the display PCB to a well calibrated Sensor module in a working frame and

power supply.

The calibration of the pressure module requires the following equipment:

- Source of known pressure with a reliable gauge or pressure measuring instrument.

Procedure:

1 S e t the jumper selections SW1, SW2, SW3 and SW5 according to the pressure

range to be calibrated.

2 S e t the calibrate/operate switch (SW4) to the calibrate position.

3 A p p l y power to the module.

4 D i s c o n n e c t the pressure sensor module and short terminals #1 and #4 of connector

J2 on the display module. Adjust R22 for zero numerical indication.

5 R e c o n n e c t the pressure sensor module and apply a known, measured pressure

(preferable at least 90% full scale) to the pressure transducer.

6 A d j u s t R25 for the appropriate numerical indication for the range and units of

display settings of SW1, SW2, SW3 and SW5. Repeat steps 4,5 and 6 until

satisfactory.

7 A p p l y an input for 50% of scale. Adjust R42 to place the bargraph display at

center.

8 C o n f i r m that the decimal select jumper SW3 will turn on either the middle or

right hand decimal points.

9 C o n f i r m that alarms are generated and that the "HI ALARM" and "LOW

ALARM" LED's flash and the "NORMAL" LED extinguishes, by changing the

pressure out of the safe area (+/- 20%), or by readjusting R42 to artificially move

the LED bar display.

10 P u t the calibrate/operate switch (SW4) to the operate position.

The Pressure Display Module is factory calibrated for set points at 40 PSI (LOW)/60 PSI

(HIGH). If you wish to change the settings, you would adjust "R42" to move the whole

range up or down. DO NOT adjust "R22" and "R25", they are factory set at "0" and full

scale. Do not adjust the potentiometers on the sensor modules, they are also factory set at

"0" and full scale. To obtain a larger or smaller range you must change "SW2" and then

adjust "R6" to obtain the proper range. You would then adjust "R42" to obtain the desired

values.