22 - FORM NO. 56041667

American-Lincoln Technology

7765 / 7760

P4134/0001

SIDE AISLES

MAIN AISLE

SIDE AISLES

P-4134

FIGURE

23

HELPFUL HINTS FOR CLEANING OPERATION

WARNING

Do not turn the steering wheel sharply when the machine is in motion. The sweeper is very

responsive to movement of the steering wheel. Do not make sudden turns.

Scrub in straight paths. Do not bump posts. Do not scrape the sides of the machine.

When the machine is in motion, do not push the directional/speed control pedal all the way forward.

This is the same as starting in “High” and will put a strain on the motor and drive system.

1. Plan your sweeping and scrubbing in advance. Try to arrange long runs with minimum stopping and

starting.

Sweep debris from narrow aisles out into main aisle ahead of time. Do an entire fl oor, or section at one

time.

2. Pick up oversize debris before sweeping.

3. Allow a few inches overlap of sweep and scrub paths. This will eliminate leaving dirty patches.

4. Don’t turn steering wheel too sharply when machine is in motion. The machine is very responsive to

movement of the steering wheel - so avoid sudden turns.

5. Try to follow as straight a path as possible. Avoid bumping into posts or scraping the sides of the

machine.

6. When placing the machine in motion, avoid slamming the directional control pedal all the way forward

quickly. This is equivalent to starting out in “HIGH” and puts needless strain on the engine and drive

system.

7. Always allow the machine to warm up before operating in cold temperatures.

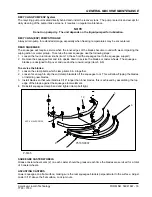

8. Periodically turn sweeping (main) broom end for end to prevent the bristles from “setting” in one direction.

NOTE

Replace sweeping broom when bristles are worn to 3-inch (8-cm.) length. Replace disc brushes when

bristles are reduced to 1/2 inch (1.3 cm) in length. Replace squeegee rubbers when all usable edges

have become rounded with wear, impairing the wiping action.