American-Lincoln Technology

FORM NO. 56041667 - 17

7765 / 7760

RECOVERY

TANK

RECOVERY

TANK

RECOVERY

TANK

RECOVERY

TANK

SOLUTION

TANK

SOLUTION

TANK

SOLUTION

TANK

DETERGENT

TANK

DETERGENT

TANK

BAFFLE

NON-RECYCLING

NON-RECYCLING

RECYCLING

RECYCLING

SOLUTION

TANK

RECOVERY

TANK

FILTER

FLOW

VALVE

ORIFICE

AUTOFIL

VALVE

CHECK

VALVE

SCRUB

BRUSH

SQUEEGEE

FILL

COUPLING

FLOOR

CONTACT

FILTER

SOLUTION

PUMP

SEPARATOR

DETERGENT

PUMP

DETERGENT

TANK

P4759a

P-4795

FIGURE

13

P-4759a FIGURE 14

SOLUTION

LINE

SOLUTION

LINE

SOLTUION

TANK

SOLTUION

TANK

RECOVERY

TANK

RECOVERY

TANK

VACUUM

VACUUM

SCRUBBING

BRUSHES

SCRUBBING

BRUSHES

P-5103 FIGURE 15

SCRUBBING SYSTEM OPERATING INSTRUCTIONS

THE SCRUBBING SYSTEM - HOW IT WORKS

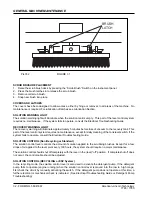

There are two scrubbing systems available for the 7765/7760 machine, the non-recycling or standard scrubbing system and the recycling

or ESP scrubbing system.

THE NON-RECYCLING OR STANDARD SCRUBBING SYSTEM - HOW IT WORKS

During the scrubbing process (shown in Figure 14), detergent solution water from the solution tank is fed to the solution line. There it is

fed to the fl oor where three disc scrubbing brushes work to dislodge soil.

After scrubbing, the dirty solution is vacuumed from the fl oor and discharged into the containment chamber in the forward portion of the

recovery tank, where a system of baffl es helps to clarify the solution. Sensors in each tank will indicate by lights on the control panel

when the water in the solution tank is too low or when the water in the recovery tank is too high.