INDOOR DOME INSTALLATION

SPEEDDOME ULTRA

2-21

Attaching the Skirt to the Indoor

SpeedDome Housing (No Bubble

Used)

The following procedure explains how to attach a

skirt to an indoor SpeedDome housing.

Install Kit Required

RHSDA Adapter Bracket*

Skirt assembly w/o bubble

1

0400-0866-01

* Only part used in this procedure is listed.

Procedure

Referring to Figure 2-23:

1. Insert the skirt’s T-lanyard into the slot in

the adapter bracket until both ends of the

“T” catch securely.

2. Push pins of the skirt into their respective

receptacles and snap the skirt into place.

Figure 2-23. Attaching the skirt to the indoor

SpeedDome housing

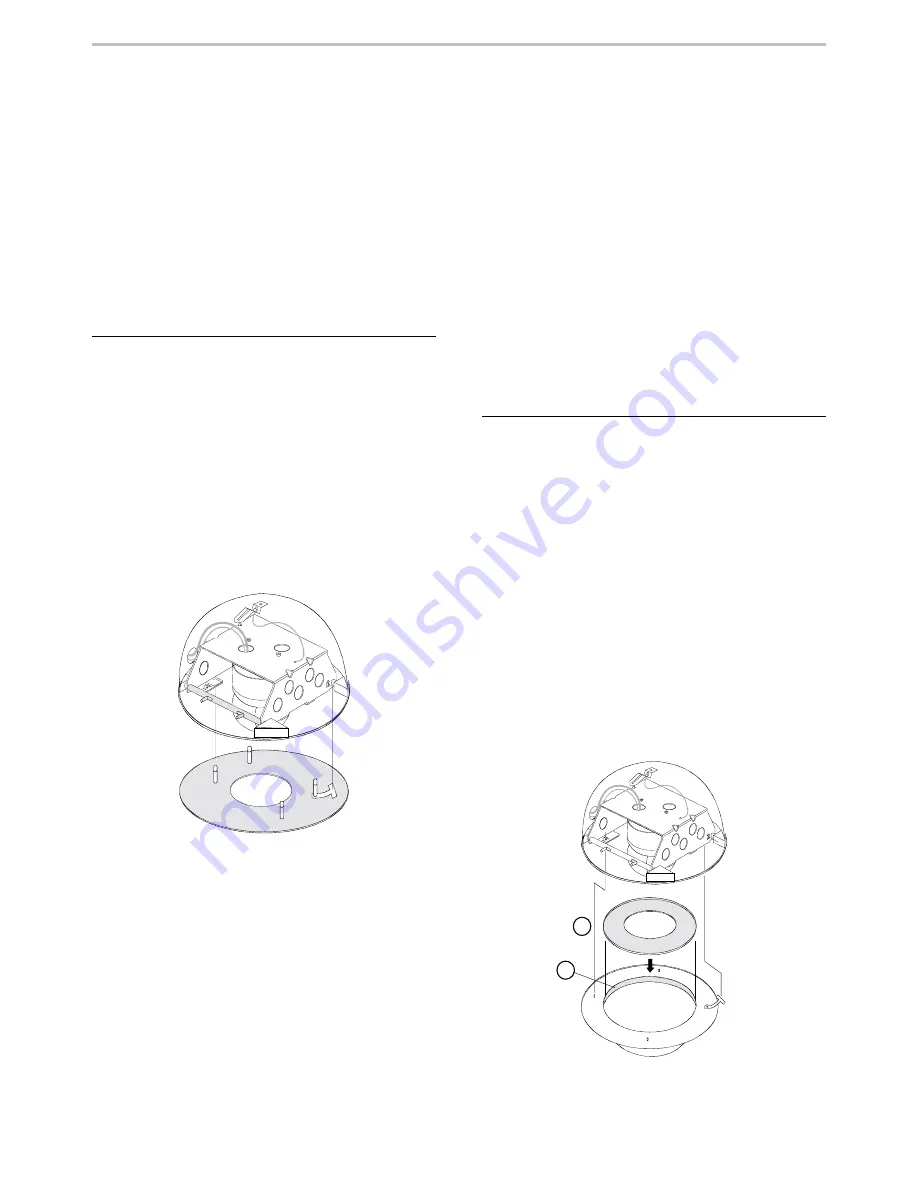

Attaching the Bubble to the Indoor

SpeedDome Housing

The following procedure explains how to attach a

bubble to an indoor SpeedDome housing.

Install Kits Required

RHSDA Adapter Bracket*

a. Skirt, inside bubble

1

0500-7411-01

b. Tape, foam, Vinyl, .062”x.5”

2.5ft

3200-0214-01

* Only parts used in this procedure are listed.

Pick Kit A, B, C, or D:

A) 0351-0386-01 Clear Bubble

B) 0351-0386-02 Silver Bubble

C) 0351-0386-03 Smoked Bubble

D) 0351-0386-04 Gold Bubble

Procedure

Referring to Figure 2-24:

1. Insert the skirt [a] into the bubble assembly.

A layer of foam tape [b] holds the skirt in place.

If the skirt drops below the tape, use the foam

tape supplied to apply an additional layer.

2. Insert the skirt’s T-lanyard into the slot in

the adapter bracket until both ends of the

“T” catch securely.

3. Push pins of the bubble into their respective

receptacles and snap the bubble into place.

Figure 2-24. Attaching the bubble to the indoor

SpeedDome housing

a

b