28

IMPORTANT:

Tighten screws evenly and progressively. Never allow the sheave to be drawn in

contact with the flange of the bushing. This gap should measure from 1/8” to 1/4”.

Proper cap screw torque is 6 ft-lbs. (26.6 newtons), if greater tightening forces are

applied, excess pressures

will

be

created in the hub of the mounted sheave which may

cause it to crack.

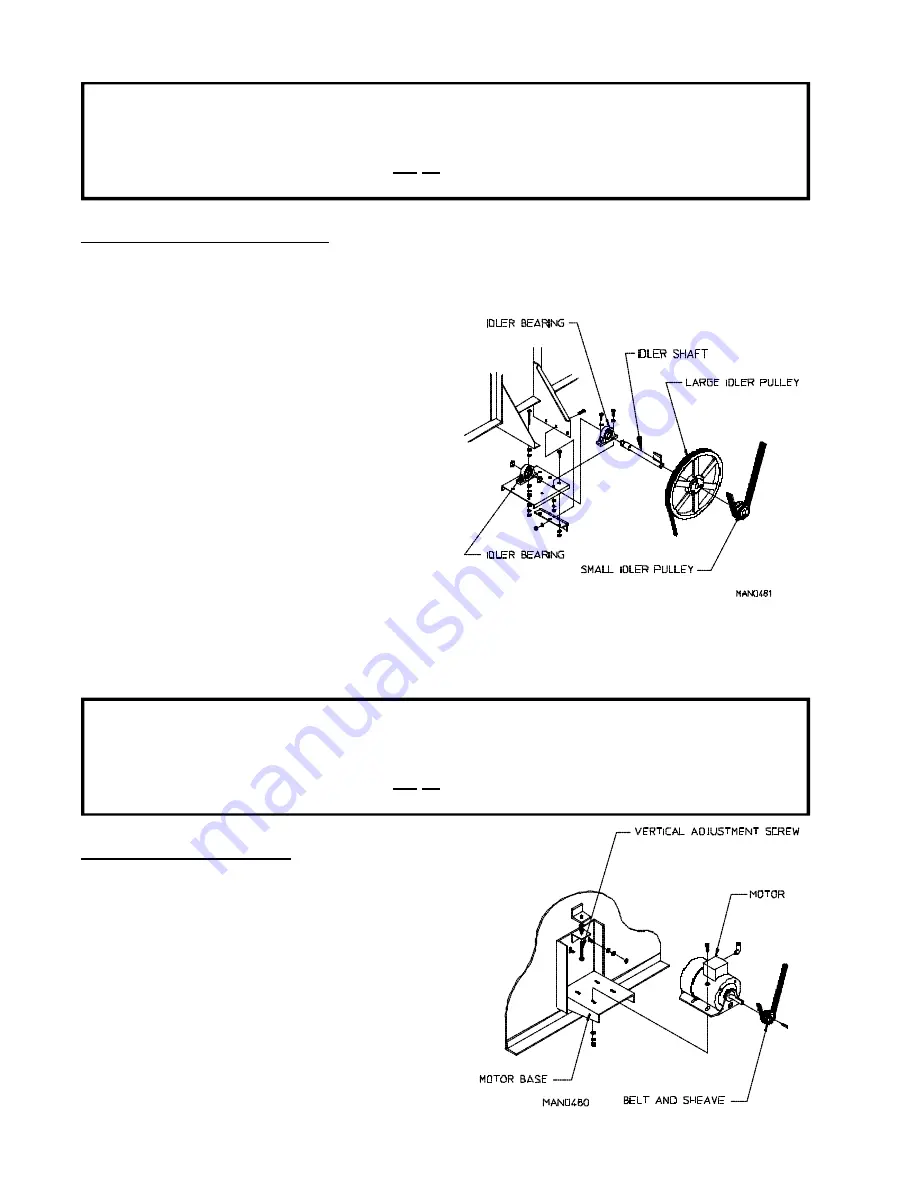

To Replace Large Idler Pulley

1. Loosen V-belts. Rotate pulley and roll V-belts out of grooves.

2. Remove cap screws from the bushing.

3. Insert cap screws in tapped removal holes and

tighten evenly until bushing becomes loose on

shaft. (Refer to figure “A” on the previous page.)

4. Remove bushing, pulley, and key.

5. Assemble bushing and sheave as shown in figure

“B” on the previous page. When cap screws

are loosely inserted, bushing remains fully

expanded to provide a sliding fit on the shaft.

6. Insert key on the shaft, then slide sheave to

desired position with cap screw heads to the

outside.

7. Tighten cap screws progressively. There should remain a gap between the sheave hub and the flange of

the bushing.

IMPORTANT:

Tighten screws evenly and progressively. Never allow the sheave to be drawn in

contact with the flange of the bushing. This gap should measure from 1/8” to 1/4”.

Proper cap screw torque is 15 ft-lbs (66.7 newtons). If greater tightening forces are

applied, excess pressures

will

be

created in the hub of the mounted sheave which may

cause it to crack.

To Replace Motor Pulley

1. Loosen V-belts. Rotate pulley and roll V-belts out

of grooves.

2. Remove cap screws from the bushing.

3. Insert cap screws in tapped removal holes and tighten

evenly until bushing becomes loose on shaft. (Refer

to figure “A” on the previous page.)

4. Remove bushing, pulley, and key.

Summary of Contents for AD-758

Page 61: ...ADC 450418 1 06 16 02 20 ...