13

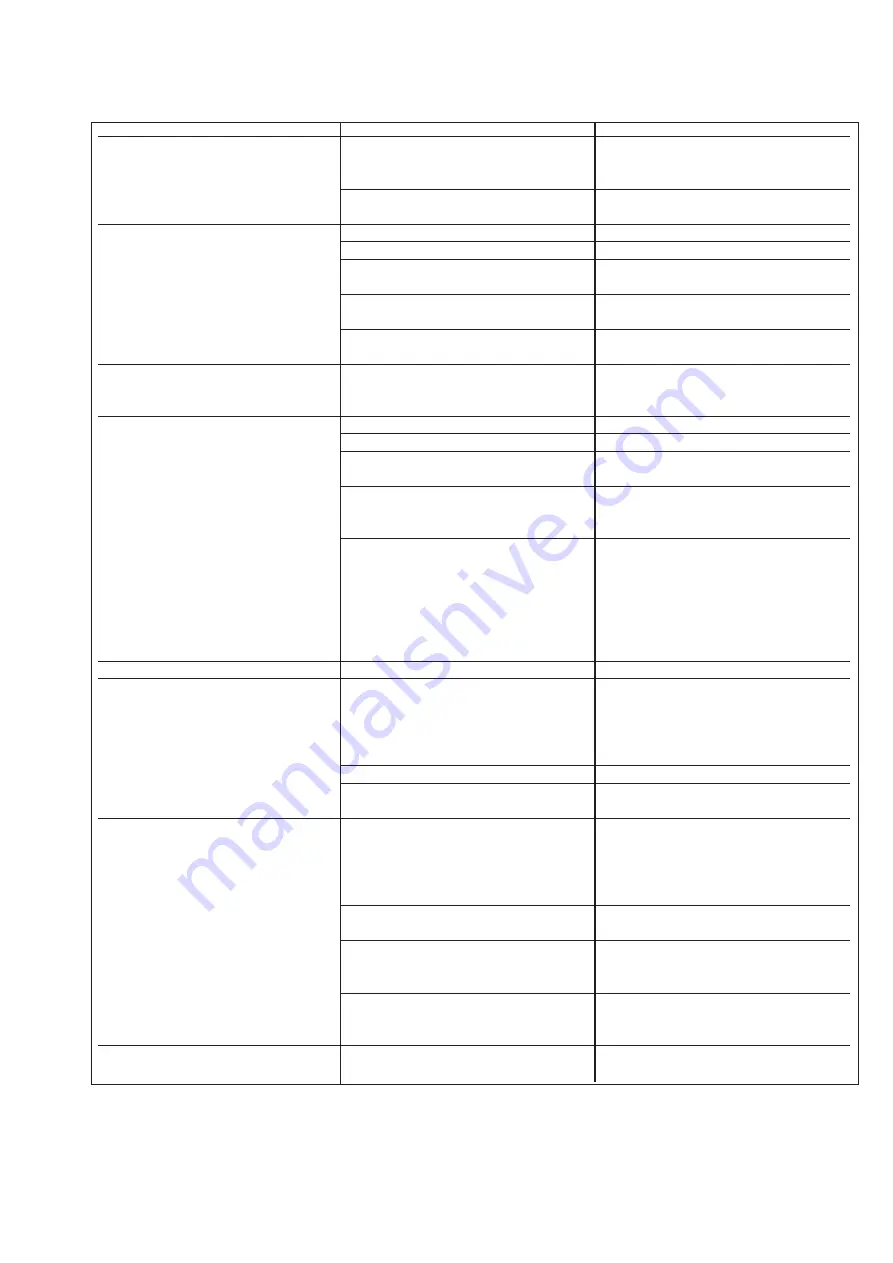

16 Trouble shooting checklist

Symptoms

Possible causes

Remedy

Burner will not start

Red ‘mains on’ does not illuminate.

External controls, thermostats, time switch etc.

Adjust controls.

not calling for heat.

Fuse blown.

Check for short circuit in wiring

or individual electrical components.

Red light illuminates.

Fan’s connector plug not fully engaged.

Engage securely.

Loose electrical connection.

Check all connections.

Fan seized or faulty motor.

Replace fan, recommission heater,

checking gas pressure settings.

Sequence controller relay failing

Check vacuum switch is satisfactory,

to pull in and/or hold in.

replace sequence controller.

Vacuum switch not returning to normal

Replace vacuum switch.

(switch off) position.

HB Herringbone system only.

Fan tripped out on overload.

Check overload setting: single phase 3 phase

0.8 amp. Reset button on in control panel.

Check for build up of condensate in fan casing.

Fan starts but burner does not attempt ignition. Insufficient vacuum generated by fan.

Clean fan blades with soft bristle.

Blocked emitter tube.

Clean emitter tube internally.

Combustion chamber cover permitting

Examine condition of sealing gasket, tighten

air leakage.

down lid securely.

Vacuum impulse line between combustion

Fix securely in place.

chamber and vacuum switch insecure

or defective.

Vacuum switch ‘pulls in’ but electronic sequence

Replace burner sequence controller unit but

controller does not proceed to programme

first check that the cause of failure is not a

ignition sequence.

short on output circuit, by measuring resistance

between pins 2 and 7 of burner control unit

plug. A reading of 10,000 ohms indicates short

circuit on gas valve burner indicator light or

associated wiring.

HB Herringbone system only.

Leaks in joint separation in manifold system.

Reseal or reconnect.

Burner proceeds to ignition stage (normally

No spark.

Check electrode for cracks – replace if necessary.

indicated by audible spark valve energised

Check high tension connections are secure.

and ‘burner on’ light illuminated) but burner

Check spark gap is 3.5 ± 0.5mm. If no high

does not light.

tension output from electronic controller,

replace controller.

Gas safety valve faulty or defective.

Replace solenoid operator section of gas valve.

Insufficient gas pressure.

Set burner pressure to that indicated on data

badge (see commissioning).

Burner lights but shuts down after

Inadequate flame signal. This can be verified

Replace electrode. Check connections to

a few seconds.

by connecting a sensitive micrometer in

electrodes and terminal 4 of electric sequence

series with the violet wire which passes through

controller plug. Replace the electronic

the combustion chamber bulkhead. The correct

sequence controller.

reading should be 6µA ± 1µA.

Flame unstable.

Check cleanliness of burner and set burner

pressure as indicated on data badge.

Inadequate gas supply. Observe burner

If gas pressure drops below that indicated on

gas pressure with all heaters operating.

the data badge, examine gas supply pipework

for excessive pressure loss.

Insufficient vacuum at combustion chamber

Clean fan blades with soft bristle brush.

causing vacuum switch to cut off.

Inspect tube internally and clean if necessary

(see servicing instructions).

Heater shuts down after operating

Refer to above.

If problem persists, replace vacuum switch.

for a period of time.