8

Operating pressures and current draw can also be com-

pared with the data given in the “Specification Sheet”. If

the system is performing properly, reinstall the service port

caps and the valve bonnets. With the valve opened, the

valve bonnet is the primary seal against refrigerant leaks.

See the table below for the torque required for an effective

seal on the valve bonnet (1/6 turn past finger tight).

Tubing Size

Torque (Foot-Pounds)

3/8

10

1/2, 5/8, 3/4

14

7/8, 1 1/8

16

After closing the valve bonnet, perform a final refrigerant

leak test on the valves and sweat connections. Return the

room thermostat to the desired settings.

TROUBLESHOOTING

(QUALIFIED SERVICE TECHNICIAN ONLY)

When troubleshooting, the first step should always be to

check for clean coils, clean filter(s), and proper airflow.

Indoor airflow should be 350 to 450 CFM per ton of cooling,

based on the size of the outdoor unit. The most common

way of establishing indoor airflow is heating temperature

rise. Indoor airflow will then be (Heating output of equip-

ment) / (1.1 x temp. rise). In other cases, measurement of

external static pressure is helpful. For details, see the

Installation Manual for your indoor equipment.

If further information is needed, see the Remote Heat

Pump Service Manual.

V. Defrost System

The RHA**B2A models are equipped with a time tempera-

ture type defrost board. Defrosting of the OD coil is

determined by both coil temperature and compressor run

time. See the “Specification Sheet” for factory settings.

Adjustment can be changed as required. There are 30, 60,

and 90 minute settings available. Adjust only if geographi-

cal conditions, outdoor humidity, or other adverse condi-

tions make it necessary.

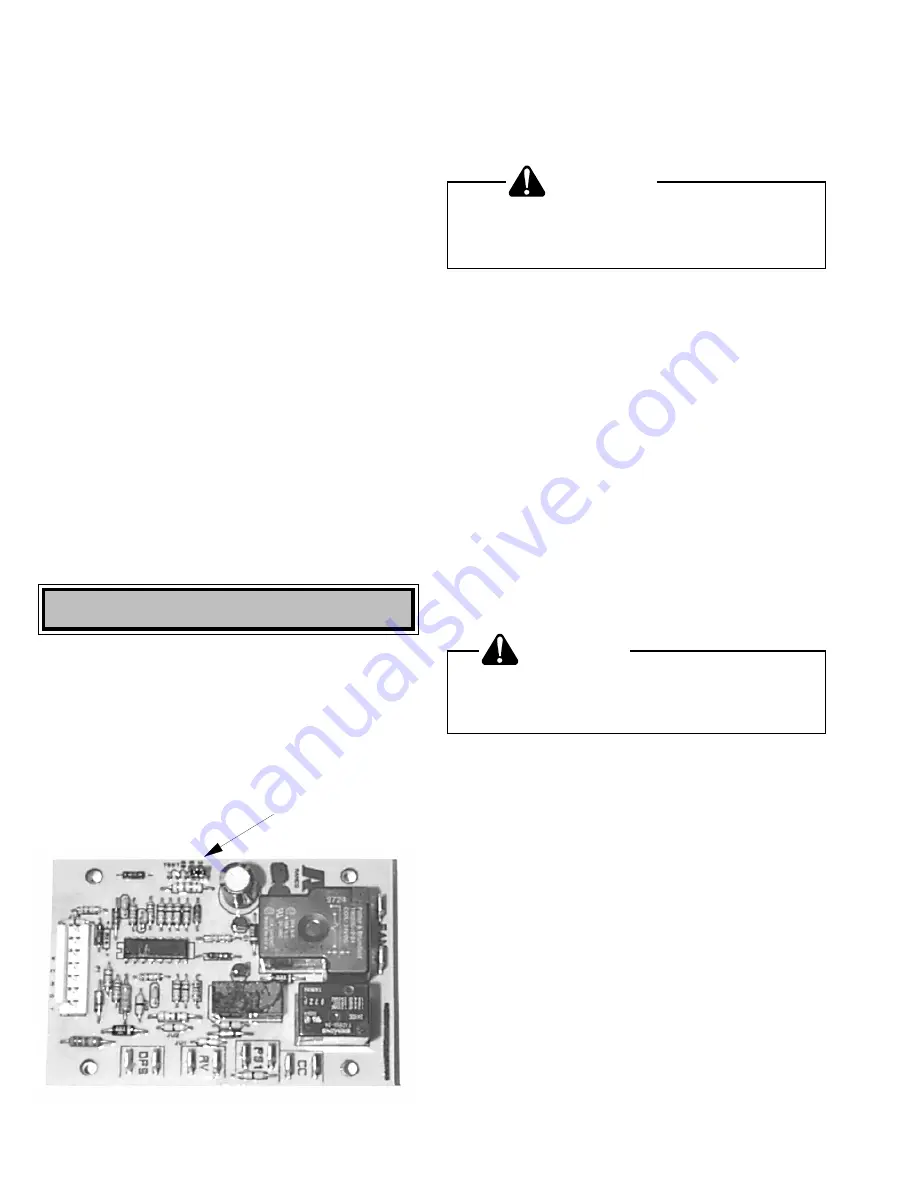

DEFROST TIME ADJUSTMENT PIN

Figure 5

NOTE: If the time select pin remains in test position for 5

minutes, the control will ignore test mode and assume a

normal 90 minute defrost cycle. To over ride this time out,

remove the select pin briefly and replace back on test.

WARNING

To avoid electrical shock or death,

disconnect the power before changing the

defrost time cycle.

If adjustment of the run time appears advisable:

1. Disconnect power to OD unit.

2. Move the defrost time adjustment pin from 90 minutes

to 60 minutes or 30 minutes as required (refer to

Figure 5).

3. Reconnect the electrical power.

The maximum defrost time is 14 minutes. Most defrost

cycles are shorter.

SERVICING: When servicing, it may be necessary to

rapidly advance the system through a defrost cycle. To do

this:

Place the defrost time adjustment pin on Test. When the

unit starts the defrost cycle, quickly remove the time select

pin to allow normal defrosting and defrost termination to

proceed. The select pin may be reconnected to test or

repeat the defrost cycle, or the pin may be placed in the

desired time setting. (Jumping both test pins with a small

insulated screw driver will also work.)

WARNING

To avoid electrical shock or death,

disconnect the electrical power before

servicing.