20

Alpha E-Tec 25R - Installation

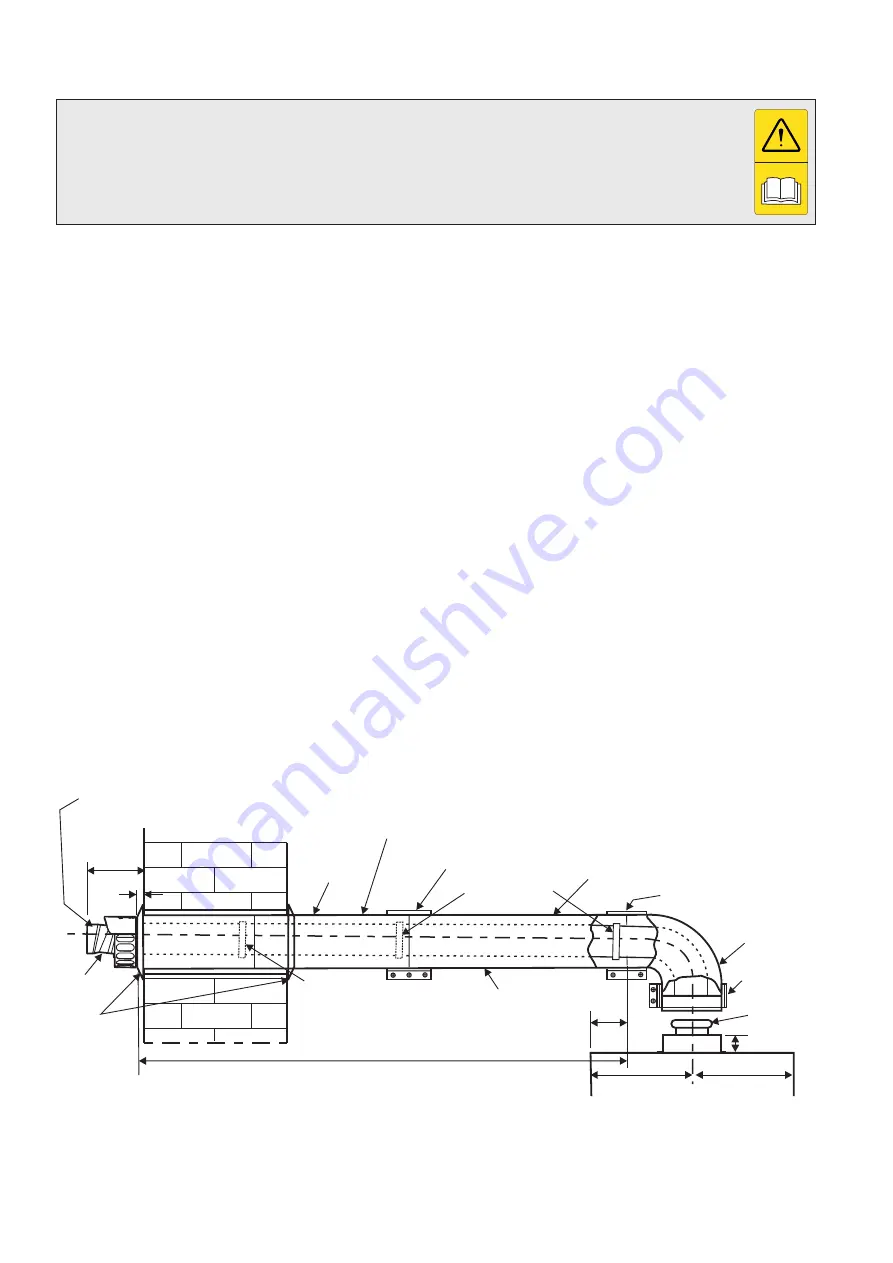

Easy-Flue 45 mm clamp

Easy-Flue

40 mm clamp

and seal

45

Front of boiler

Extension clamp

Inner seal joint

Inner seal joint

Flue length (L)

90° bend

Seal joint

CD Easy-Flue

Ensure outer flue duct of Easy-Flue is horizontal

Ensure the flue extension slopes

downwards towards the boiler by a

minimum of 25 - 30 mm per metre

CD Flue extension

Flue sealing

collar

Ensure the inner duct within the terminal is at the top.

The inner duct must be positioned to slope towards the boiler

Note:

120

Terminal

20

115

180

210

Fig. 5.11 - Side flue

5.8 EXTENDING THE FLUE - Fig. 5.11

Note:

The flue assembly length must not exceed the maximum length stated, including the equivalent lengths

of any extensions, bends etc. used for plume management components.

E-Tec boilers must not exceed the

maximum of an equivalent horizontal flue length of 12 m.

1. When the flue length required is more than the maximum stated in Section 5.6, paragraph 1, refer to the table below

and Figs 5.5 and 5.6.

Alpha CD 750 mm flue extension (Part No. 6.2000750) or 1000 mm extension (Part No. 6.2001050) is

required to extend the range of telescopic flue.

Refer to Section 5.8 for instructions on how to extend the flue.

Note:

A 130 mm flue hole (127 mm core drill) may be required in the wall. This is when the extended flue is passed through the

wall.

Additional support brackets are required when extending the flue. These are available from Alpha, Part No. 6.1000355.

2.

Use the template (supplied with the boiler) to mark the required flue position, ensure the slope towards the boiler is correct.

3. Determine the overall flue length as described in Section 5.6, paragraph 2 to determine the number of Alpha CD 750 or

1000 mm flue extensions required.

4. Assemble the flue extensions together by locating the inner duct into the seal joint and secure each extension together

with the extension clamps supplied (three screws). Ensure that the clamps are positioned centrally over the joints.

Note:

If it is required to cut an extension,

DO NOT

cut the end of the inner duct that incorporates the seal joint. Ensure

the inner duct end without the seal joint is cut so that it is 20 mm longer than the outer duct.

Ensure that all cuts are square and free from burrs.

Once assembled with the components pushed home, the flue is fully sealed.

5. Adjust the telescopic section of the Easy-Flue to the required length and secure the Easy-Flue with the sealing tape

supplied. Fit the Easy-Flue to the extensions by locating the inner duct into the seal joint and secure with the clamp

(three screws), ensuring it is located centrally over the joint.

6. Mark the end of the flue assembly 'TOP' where it is connected to the boiler, so that the 'TOP' of the flue terminal is

aligned with the 'TOP' at the boiler end of the flue assembly.

7. Pass the complete flue assembly through the wall.

8. Position the smaller Easy-Flue 40 mm clamp (with seal) supplied, over the bend. Fit the bend to the boiler and rotate to

the correct position and secure in position. Ensure the seal is located centrally over both the bend and boiler adaptor. If

the inside sealing collar (white) is being used to make good the inside wall, then it will need to be fitted before assembling

the flue.

9. Slide the larger Easy-Flue 45 mm clamp (two screws) over the outer duct and pull the flue assembly towards the bend,

locating the inner duct into the seal joint on the bend.