16

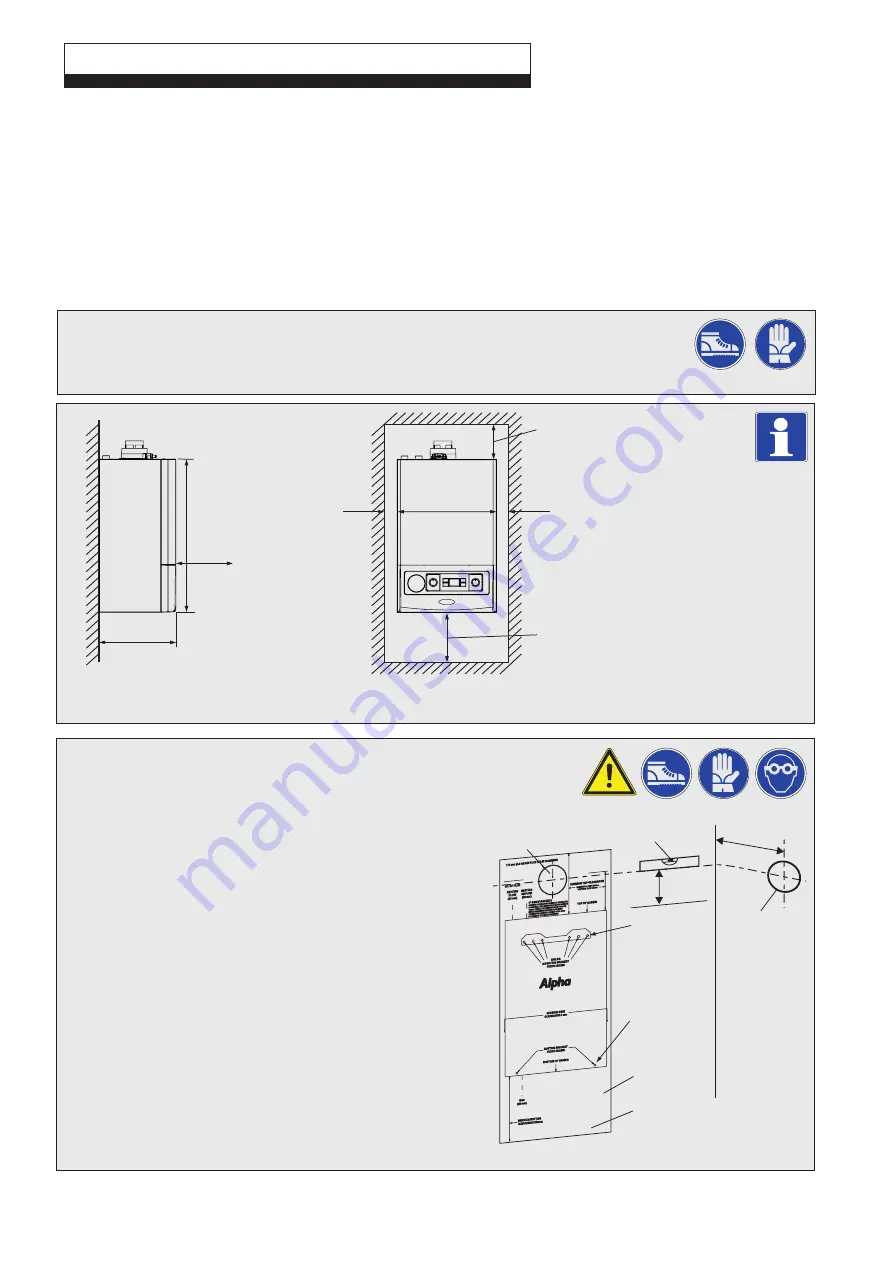

5.3 PREPARE THE WALL - Fig. 5.2

1.

Decide upon the position of the boiler taking into account the clearances required

for servicing and the flue terminal position.

2.

Tape the template to the wall (ensure it is level and the right way

up) and mark the position of the holes for the boiler mounting

bracket. If rear exit flue is used, mark the position of the hole for

the flue.

3.

Side exit flue -

Continue the horizontal centre line of the flue

across the wall to the side wall, then along the side wall 138 mm

(ensure the lines are horizontal). This will give the position of the

centre of the hole for the flue.

4. Cut the 110 mm diameter hole (or use a 107 mm core drill) in

the wall for the flue.

Notes: 1.

Ensure the hole is horizontal.

2. For internal fitting

of the flue, using the flue sealing

collar supplied, cut a 130 mm dia. flue hole using a 127

mm core drill.

5. Drill the fixing holes (10 mm dia.) to accept the No.10 plugs

supplied. Using the screws supplied, fit the mounting bracket.

5 INSTALLATION

Fig. 5.1

Alpha E-Tec 25R - Installation

5.1 UNPACKING

1. The boiler carton also contains the following:-

Connection kit (union bends, washers and gas service cock)

Mounting bracket plus screws and wall plugs

Condensate discharge pipe

Literature pack and Wall template

A suitable Alpha flue system must be selected to use with the boiler.

Notes:

a. All flues must be suitable for Alpha condensing boilers.

b. CD 750 mm and 1000 mm flue extensions are available, if required.

Damaged products must not be used.

2. Unpack boiler and remove the loose items, packs and mounting bracket.

Note:

The boiler can be stood in an upright position (only while the valves and union bends are not

fitted).

It is recommended that two persons lift the boiler.

5.2 CLEARANCES REQUIRED - Fig. 5.1

Fig. 5.2

Minimum clearances

5 mm

5 mm

250 mm

390 mm

235 mm - Can be reduced to

150 mm when using a

vertical flue

600 mm

Minimum

clearance

of 450 mm

from front

of boiler

300 mm

Template

Outline of

boiler

138 mm

Ensure line is level

Rear exit hole

110 mm dia.

Position of

110 mm hole

to be cut for

side exit flue

141 mm

Boiler bottom

fixing holes

Fixing holes

for mounting

bracket

HEATING

FLOW

(22 mm)

HEATING

RETURN

(22 mm)

IF SIDE FL

UE EXIT:

110 mm (4

.3 in) MIN

FLUE HOL

E DIAMET

ER

C/L OF FL

UE

MINIMUM

TOP CLEA

RANCE

TOP OF C

ASING

MINIMUM

SIDE

CLEARAN

CE 5 mm

BOILER

MOUNTIN

G BRACKE

T

FIXING HO

LES

BOTTOM

BRACKET

FIXING HO

LES

BOTTOM

OF CASIN

G

GAS

(22 mm)

MINIMUM

BOTTOM

CLEARAN

CE 250mm

CONTINUE C

ENTRE LINE

HORIZONTA

LLY ACROSS

WALL

TO SIDE WA

LL. THEN HO

RIZONTALLY

ALONG SIDE

WALL

138 mm. THIS

WILL GIVE

CENTRE OF

HOLE FOR

FLUE.

ENSURE TH

E FLUE EXT

ENSION(S) S

LOPE DOWN

TOWARDS T

HE BOILER

BY A MINIMU

M OF 25 - 30

mm

PER METRE

OF FLUE EX

TENSION(S)

USED.

HORIZON

TAL FLUE

235mm

VERTICAL

FLUE 150m

m