78

Rockwell Automation Publication 842E-UM001C-EN-P - September 2016

Appendix B

RSLogix 5000® Sample Code

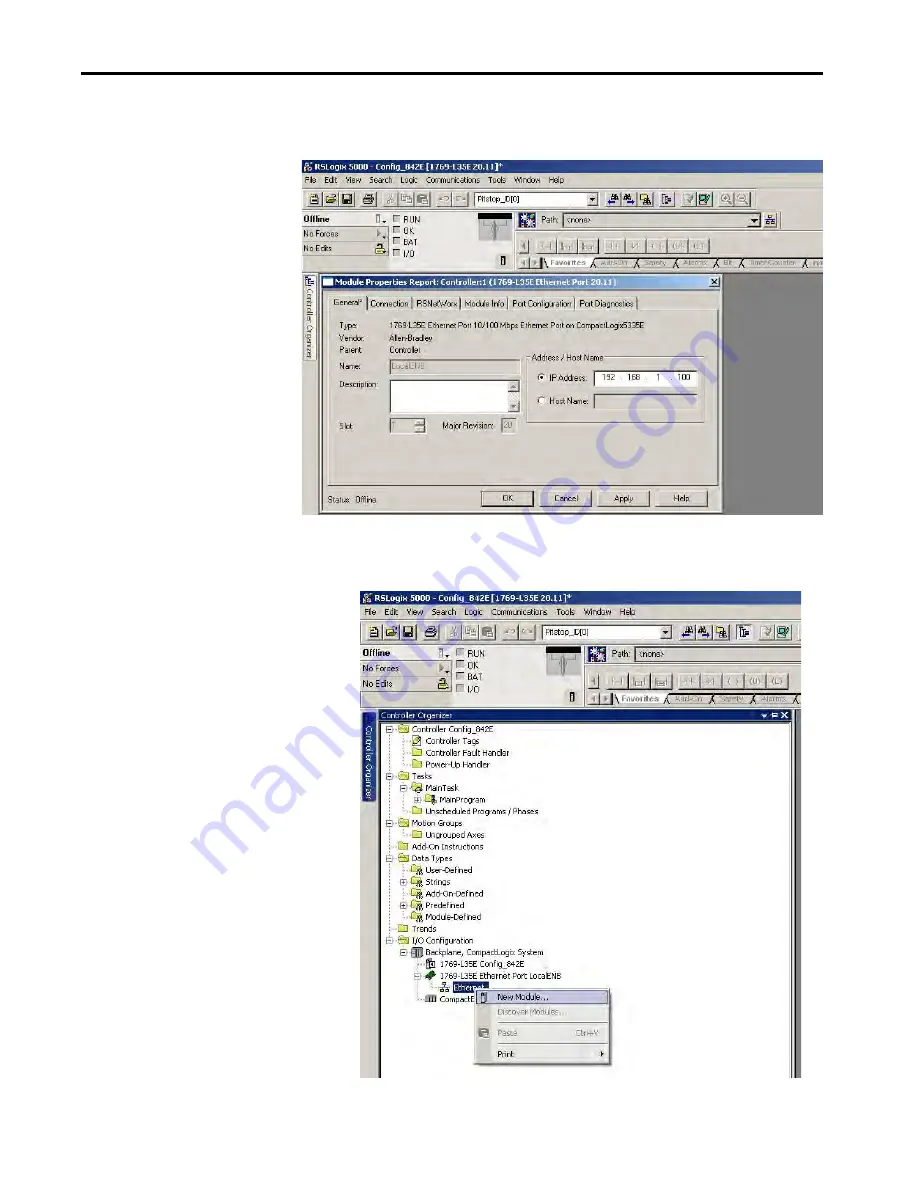

3. Configure the controller IP address, this example uses 192.168.1.100.

Click

Apply

, then

OK

.

Figure 3

4. Right-click

Ethernet Network

and select

New Module

.

Figure 4