8

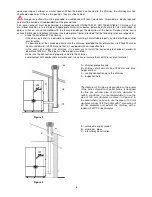

Figure 8 – End of the chimney

Maximum allowed length of 80 mm diameter flue gas pipe to its point of entering the chimney is 6 m. After that the

diameter of a flue gas pipe must be increased to 110 – 120 mm. In that case, each elbow accounts for 1 m length.

For example, if there are three bends of 80 mm diameter, the length of the flue gas pipes of 80 mm diameter is

thus changed by 3 m. Just another 3 m of a straight pipe may be placed to the entrance of the chimney, in order to

get 6 m length of the flue gas pipes of 80 mm diameter. After that, the bend must be enlarged, led back to flue gas

pipes or should enter the chimney of a greater diameter, 110 – 120 mm.

Care should be taken not to use bends of a sharp angle of 90°. They must be of a certain radius or made in

segments. Sharp angle bend increases resistance to flow of the smoke through the bend.

-

Each bend must be equipped with the cleaning door.

-

Joints between the connection pipes must be tightened.

-

For greater spacing, use 100 mm diameter connector. In that case, length of up to 8 m is allowed.

Note:

The chimney shall be adapted or constructed in accordance with the instructions indicated. Each boiler must be

adapted and parameters must be adjusted according to the chimney to which they are connected. This

adjustment, i.e. putting into operation, is done by a competent person – service personnel.

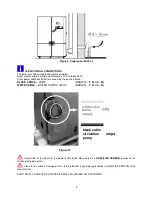

3.3 INSULATION AND ROOF OPENING DIAMETER

When position of instalation of the boiler is known, it is necessary to make a hole/opening allowing flue gas flow.

This position is changed depending on the type of installation, diameter of flue gas uptake and the type of the walls

or the roof through which it will pass. Insulation must be mineral type insulation (rock wool) of 80 kg/m

2

nominal

density. Draft of the chimney depends mainly on the chimney itself, which must be free from obstacles, such as

bottlenecks or various angle connections. It is recommended that the bends of a chimney should not be larger

than 45°.

Proper exhaust of flue gases requires installation of a vertical straight pipe of minimum length of 1.5 m.

3.4 COMBUSTION AIR

The air needed for proper combustion, which comes from the area, must be made up by new batch of air through

the openings running on the wall, on the door of the boiler room, or simply by opening the window. This allows

better boiler operation, lower ash consumption and prevents shutting down of the boiler.

Opening for fresh air supply must be placed on the outer wall and protected by a mesh against the entry of insects

and other animals, and located so that it prevents the entry of water into the boiler area.

Standard UNI 10683 prohibits supply of fresh air required for combustion from the storage of

flammable material or areas where there is a possibility of ignition.

In the case that in the area containing the boiler pellet there are other devices that need air for

combustion, it is necessary to identify that and bring a sufficient quantity of air required for combustion.

Y

N