11/23

ALFA IN a.s. ©

www.alfain.eu

3. If there is a suitable groove on the roll, rotate the roll and place it back on

the shaft and secure it by screwing the element

E5

.

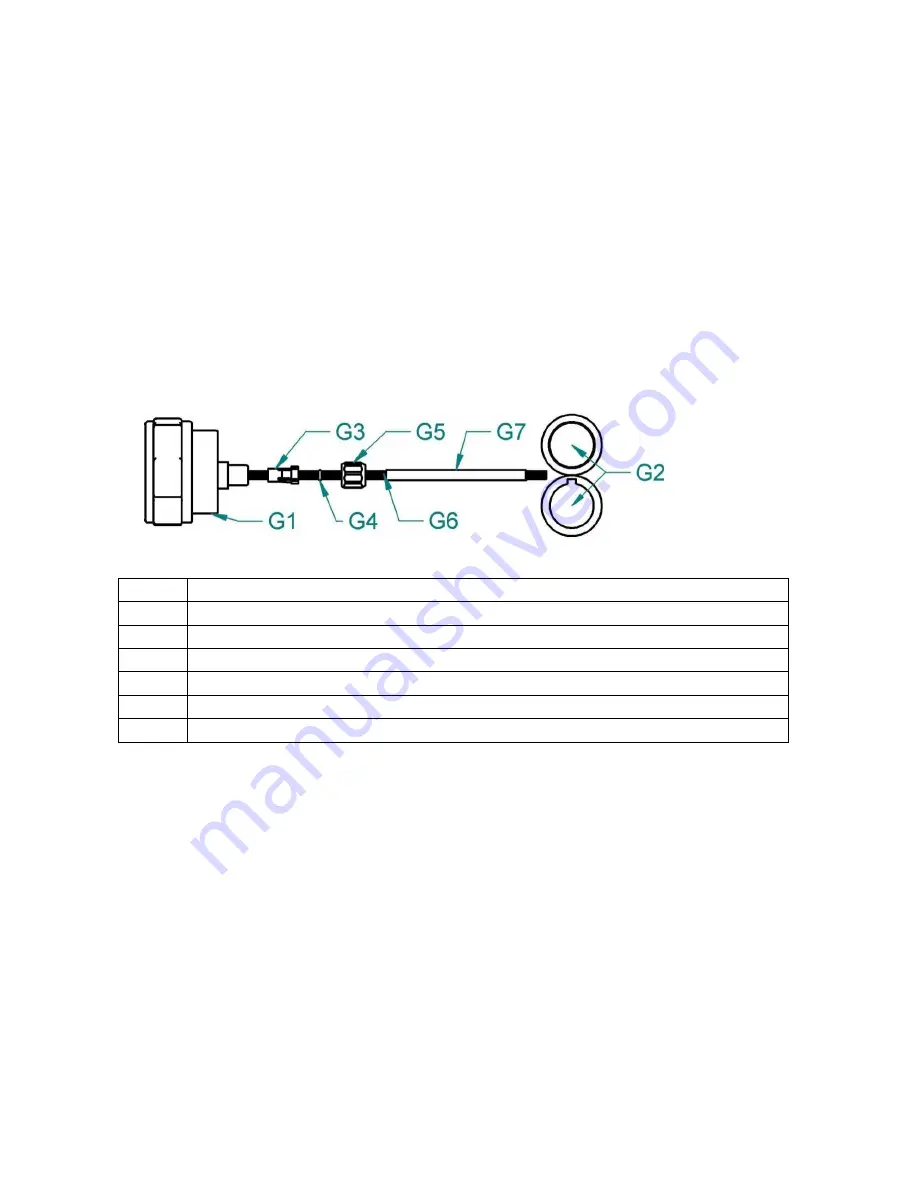

ADJUSTING THE MACHINE FOR WELDING OF ALUMINIUM

For feeding the AL wire it is necessary to use roll with the “U” profile - see

paragraph OVERVIEW ROLLS WIRE FEED. To prevent problems with feeding

use wires with diameter. 1.0 mm of AIMg3 or AlMg. Wire of alloy Al99, 5 or AlSi5

are too soft and easily will cause problems with movement.

For the aluminum welding it is also necessary to provide the torch tefl. liner and

special current nipple. We do not recommend you to use the torch longer than 3

m. Great attention must be paid to adjust the contact power of rolls – it must not

be too high, otherwise there is a deformation of the wire.

As a protective atmosphere is necessary to use argon.

Picture

4

– Customization of the feed for the aluminium wire

G1

EURO connector

G2

Rolls

G3

Liner terminal for 4,0mm, 4,7mm outer diameter

G4

O-ring 3,5 x1, 5mm to prevent escape of gas

G5

Nut

G6

Liner tefl.

G7

Sustain pipe for teflon and plastic liner

INSERTING THE WIRE

1. Open the side cover of the wire feeder space

2. Put the wire spool on the wire spool holder

D1

and fix it with the fixing nut

D2

. If a spool (size of 15 or 18 kg) is used, put on each side of the spool

adapter

D3

. The hole in the back of the adapter must fit into the pin on the

wire spool holder!

3. Cut off the curved or damaged end of welding wire and lead it through the

inlet liner

E3,

and the roll into the liner inside the EURO torch connector

(about 5 cm). Make sure, that you use the suitable groove.

4. Put the pressure arm

E2

down in that way, that the teeth or the gear fit and

fix it by setting the lever

E1

into vertical position.

5. Adjust the pressure nut that way that it provides constant movement of

wire but it does not deform wire. The adjusting screw is located under the

plastic screw

E1

.