SFBTT20-IT BOBTAIL® Hydraulic Tool

(HK1121)

Alcoa Fastening Systems

6

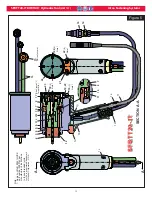

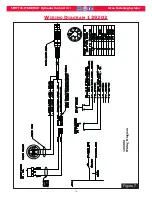

POWER SOURCE CONNECTIONS

Coat hose fitting threads with a non-hardening

Teflon

TM

thread compound such as Slic-tite.

TM

(Slic-tite is available from Huck as part number

503237.)

2. Use only a Huck POWERIG 918, 940, or equiva-

lent that has been prepared for operation per

applicable instruction manual. Cheek both PULL

and RETURN pressures and adjust as necessary

to match installation tool. Gage part number T-

124833(new), for checking POWERIG pressures

is available from Huck.

3. Turn POWERIG to “OFF” and couple tool hoses

to POWERIG hoses.

5. Turn POWERIG to “ON” and depress and release

trigger a few times to circulate hydraulic fluid.

Observe action of tool. Check for fluid leaks.

6. Attach the proper Nose Assembly to the tool.

P

P

REPARATION

REPARATION

FOR

FOR

U

U

SE

SE

CAUTION: Do not let disconnected hoses

and couplers contact a dirty floor. Keep

harmful material out of hydraulic fluid. Dirt

in hydraulic fluid causes valve failure In Tool

and In POWERIG Hydraulic Unit.

WARNINGS:

Read full manual before using tool.

A half-hour training session with qualified

personnel is recommended before using

Huck equipment.

When operating Huck installation equip-

ment, always wear approved eye protection.

Be sure there is adequate clearance for the

operator’s hands before proceeding.

CAUTION: Do not use TEFLON

®

* tape on pipe

threads. Pipe threads may cause tape to shred

resulting in tool malfunction. (Slic-Tite is avail-

able in stick form as Huck P/N 503237.)

WARNING: Correct PULL and RETURN pres-

sures are required for operator’s safety and

for Installation TooI’s function. Gauge Set-Up,

T-124833 and T-124833CE, Is available for

checking pressures. See Tool S

PECIFICATIONS

and Gauge Instruction Manual. Failure to ver-

ify pressures may result in severe personal

injury.

WARNING: Be sure to connect Tool’s

hydraulic hoses to POWERIG Hydraulic Unit

before connecting Tool’s switch control cord

to unit. If not connected in this order, severe

personal Injury may occur.

CAUTION: Hose couplers must be completely

screwed together to insure that ball checks

in both nipple and body are completely open.

Improperly assembled couplers will cause

overheating and malfunctions in both tool

and Powerig. Hand tighten couplers. Do NOT

use a pipe wrench.