SFBTT20-IT BOBTAIL® Hydraulic Tool

(HK1121)

Alcoa Fastening Systems

7

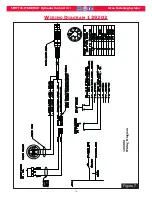

* Two digit number after dash indicates hose

length in feet. (Example: 118309-12 is 12 foot

hose assembly.)

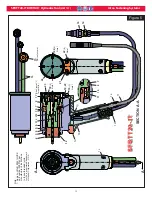

SFBTT20-IT

Nose

Assembly

918

Powerig

Shown

To primary power source

118308-*

Cord Assy

(2-Wire)

918

Powerig

128441-3

3-Tool Controller

115 VAC

15A Plug

128418-*

Cord Assy

128457-*

Cable Assy

(Pressure

Transmitter)

125926-*

Hose Assy

128415

Relief

Valve

Transducer

2

3

4

5

6

7

8

9

10

1

TOOL 1

TOOL 1

CAUTION

CAUTION

ON

O

FF

POWERIG HYDRAULIC UNIT

CAUTION

TOOL 2 15 VAC

24 VAC

TOOL 2

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

TOOL 1

Figure 3

T

T

OOL

OOL

TO

TO

P

P

OWERIG

OWERIG

S

S

ETUP

ETUP

NOTE: To decrease Relief Valve pressure, turn

the Relief Valve handle gradually counterclock-

wise; turn clockwise to increase pressure.

1. With the Nose Assembly in place on the

Installation Tool, begin setup.

2. Connect the Hydraulic Hoses to the Powerig.

3. Connect the Relief Valve to the other end of the

Powerig Hydraulic Hoses.

4. Connect Hose Assy to the Transducer (PULL

pressure) and Relief Valve (RETURN pressure).

5. Connect Cord Assy from the Controller to the

Powerig labeled TOOL 1.

6. Connect Cable Assy from the Controller to the

Transducer.

7. Connect the Hose Assy to the installation tool.

8. Connect the Cord Assy to the installation tool.

9. a. Connect the other end of Cord Assy to the

Controller at TOOL 1.

b.

Connect optional Hose/Cable Assy.

10. Connect the electrical plug from the Controller to a

120 VAC 15amp power.

continued

WARNING: To prevent tripping hazard, sus-

pend tools and route hoses off of floors.

WARNING: Only use compatible equipment

with this tool.