SFBTT20-IT BOBTAIL® Hydraulic Tool

(HK1121)

Alcoa Fastening Systems

9

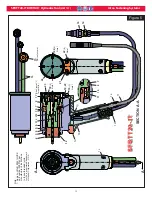

Figure 4

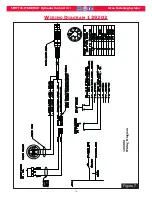

128441-3 C

128441-3 C

ONTROLLER

ONTROLLER

UL & Serial

No. Sticker

Instructions &

Wiring Diagram

Digital

Display

PLC

Arrow

Buttons

Command

Buttons

ESC - MENU - ENT

3-Position

Mode

Switch

A

S

S

HIPPED

:

Controller Pressure:

4200 psi.

Hold Timer:

500 (.50 seconds).

Eject Timer:

600 (.60 seconds).

1. Move the 3-Position Mode Switch on the PLC to

“STOP” (right-most position).

2. Press the

MENU

Command Button to enter the

“Monitor” menu.

3. Press the

ENT

Command Button to select “Data

Monitor”. Press

ENT

again to select “V” data type.

4. Enter the address button of the value you need to

alter. Use the left (◄ ) and right ( ►) buttons to

position the cursor. Use the up ( ▲ ) and down

( ▼ ) buttons to change individual digits. Press

the

ENT

Command Button when finished.

5. Press the

ENT

Command Button to enter the

“Change” menu.

6. Use the arrow buttons again to enter the new

value. Press

ENT

when finished.

7. Press the

ESC

Command Button 5 times to exit.

8. Move the Mode Switch back to “RUN” (left-most

position).

9. Check the continuously scrolling display for your

new value before using the Tool again.

“V“

ADDRESS

DESCRIPTION

RANGE

DEFAULT UNITS

07411

T1 Press. SetPt 1000-9999

4200

psi

07412

T2 Press. SetPt 1000-9999

4200

psi

07413

T3 Press. SetPt 1000-9999

4200

psi

07421

T1 Hold Timer

0-3000

500

msec

07422

T2 Hold Timer

0-3000

500

msec

07423

T3 Hold Timer

0-3000

500

msec

07431

T1 Eject Timer

250-3750

600

msec

07432

T2 Eject Timer

250-3750

600

msec

07433

T3 Eject Timer

250-3750

600

msec

SET POINT ADJUSTMENTS

The active set points are displayed continuously while the Controller is in RUN mode. Stopping the Controller (which

also stops Tool sequencing) allows the user to enter the Controller menu to make adjustments.

Do not begin this

procedure if any of the Tools are still in use.

M 3

:

D A T A

T Y P E

V

A D D R E S S

0 0 0 0 0

M 3

:

>

D A T A

M O N

I

T O R

> B

I

T

M O N

I

T O R

M 3

:

D A T A

V

0

C H G =

0

0 0 0

0 0 0 0