5

–3

MAINTENANCE OF THE BATTERY AND

BATTERY CONNECTIONS

: Stop the generator before starting

any work on the battery. Ventilate the area

and around the area where the batteries are

placed in proper conditions. Always wear

safety goggles. Battery acid is very corrosive,

be very careful. Do not smoke while you are

working.

Take any equipment that generate flames,

sparks and arcs and all other flammable

sources away from these areas. Explosions,

fires and damages that may occur due to this

may cause serious injuries, and even lethal

accidents. Always disconnect the negative

(-) battery cable firstly, and re-connect the

negative (-) battery cable lastly to decrease

any arcs when you are disconnecting the

battery cables.

Follow the battery manufacturer’s instructions

first for the maintenance of batteries. (Page 5-1)

Check whether the battery connection points are

loose and check for any oxidation. Loose, worn

and oxidized connections cause high electrical

resistance that leads to rough running of the

engine. Before any operation, always:

1. Keep the battery and connection points

clean, dry and tight.

2. Always disconnect battery terminals on

the ends of battery cables using a proper

wrench.

3.

Make certain which terminal is (+) and

which is (-) before making the battery

connections, always disconnect the

negative (-) battery cable first, and re-

connect the negative (-) battery cable

last.

CHECKING ENGINE OIL LEVEL

: Engine oil contact may cause

intoxication. Avoid direct contact with engine

oil and inhale vapors in hot conditions. Use

gloves while you are working. Wash any

parts of your body that had contact with

engine oil.

: Low oil level may cause serious

engine damage. And excessive oil may cause

oil consumption. Always check oil level

before starting the engine.

Check the oil level in the engine with the

dipstick about 10 minutes after stopping the

generator. Add oil or drain oil according to

the required level.

REPLACEMENT OF ENGINE OIL AND FILTER

Refer to the periodical maintenance chart for

regular engine oil replacement. (Page 5-1)

Operate the generator set until it reaches the

proper operating temperature. Stop the

generator and remove the battery negative (-)

terminal.

: Inadvertent or remote operation

of the engine may cause personal injuries or

death. Always disconnect battery terminals

before working on the engine. Always

disconnect the negative (-) battery cable

firstly, and re-connect the negative (-) battery

cable lastly to reduce any arcs when you are

disconnecting the battery cables.

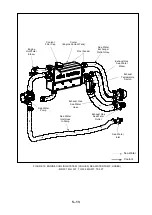

2.

Select a container suitable for the

capacity of the oil and open the manual

oil pump (Page 5-5, Page 5-6, Page 5-7,

Page 5-8 ) valve, and then drain the oil

by moving the pump up and down

manually.

3.

Close the pump valve. Separate old oil

filter with a filter wrench, and clean the

filter installation surface.

4. Apply a thin coat of oil to the gasket on

the new filter and fill the new filter with

some oil so that it can reach engine parts

more quickly.

5. Fill with engine oil of a suitable type and

amount for the engine. See ENGINE OIL

RECOMMENDATIONS (Page 4-2 ).

Check the oil level, and add or drain oil as

required. Operate the engine for a few

minutes, turn the engine off, and check

for proper oil level again.

6. Dispose used oil and oil filter as per the

local environmental legislation.

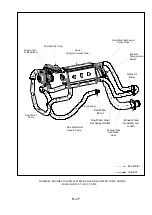

REPLACEMENT OF FUEL FILTER

: Diesel fuel is a flammable

substance. Uncontrolled ignition or

combustion of the fuel may cause material

damage, and the damages thus occurred may

cause serious injuries, and even lethal

accidents. Do not smoke near fuel tanks or

fuel combustion equipment or any area that

shares the ventilation system with this

equipment. Keep flames, sparks, pilot lights,

electrical arcs, and any other igniters like

switches operated electrically away from

these flammable sources and keep a multi-

class ABC extinguisher in a close place

where you can reach easily during all

maintenance and repair work.

Summary of Contents for MG 309

Page 4: ......