Technical Reference Manual for

OMNI-A0092

Author

C. Vale

Creation Date

2010-04-29

Product

OMNI-A0092

Revision Date

Name:OMNI-A0092_TRM.doc

Company Confidential

Version 1.0

Page 8 of 55

2.1.1.2

Fasteners

M8 Stainless steel bolts are recommended for bolting down the unit. The length is to be

determined by the nature of the mounting platform, so the fasteners have not been provided

with the antenna. Mild steel bolts are not recommended due to the high likelihood of

corrosion.

2.1.1.3

Location and Orientation

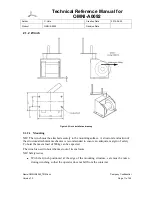

The „back‟ of the main antenna assembly is defined as the end whose face has the antenna

nameplate and hazard stickers

located. On a vehicle, this typically corresponds to the back

of the vehicle. The front of the main antenna assembly corresponds to the end closest to which

the winch must be located.

When selection a mounting location, it is therefore necessary to ensure there will be sufficient

space at the front of the main antenna assembly to find a place to mount the winch. As shown

in Figure 3, the back of the main antenna assembly can be mounted flush with the back of the

mounting platform.

Also take note that space (no less than 0.5m is recommended) to the sides of the main antenna

assembly is necessary, to provide a location for the guy rope anchoring brackets.

2.1.1.4

Lifting of the main antenna assembly

The main antenna assembly is a large and heavy unit that needs special care when being

handled. The unit is 4114mm long, 614mm wide and 500mm high. The unit weighs 350kg.

The unit must under no circumstances be mechanically hoisted by its

handles. The handles are not rugged enough for mechanised

hoisting. (See 2.1.1.4.1 for lifting by hand)

2.1.1.4.1

Lifting the unit by hand

Lifting the unit by hand is only recommended to a maximum of table height, for short

distances and manoeuvring the unit in place.

A total of 8 handles are provided (4 on each side of the unit). The unit must under no

circumstances be mechanically hoisted by its handles. The handles are not rugged enough for

mechanised hoisting.

Moving the unit by hand requires a minimum of 8 able bodied individuals.

For lifting by hand the weight of the unit must be distributed across the 8 handles. This means

that 8 people must carry the unit with each person taking his share of the weight at each

handle.