Page 33

aERO MODEL TyPE

Changing Servo End Point Percentage Values, Continued....

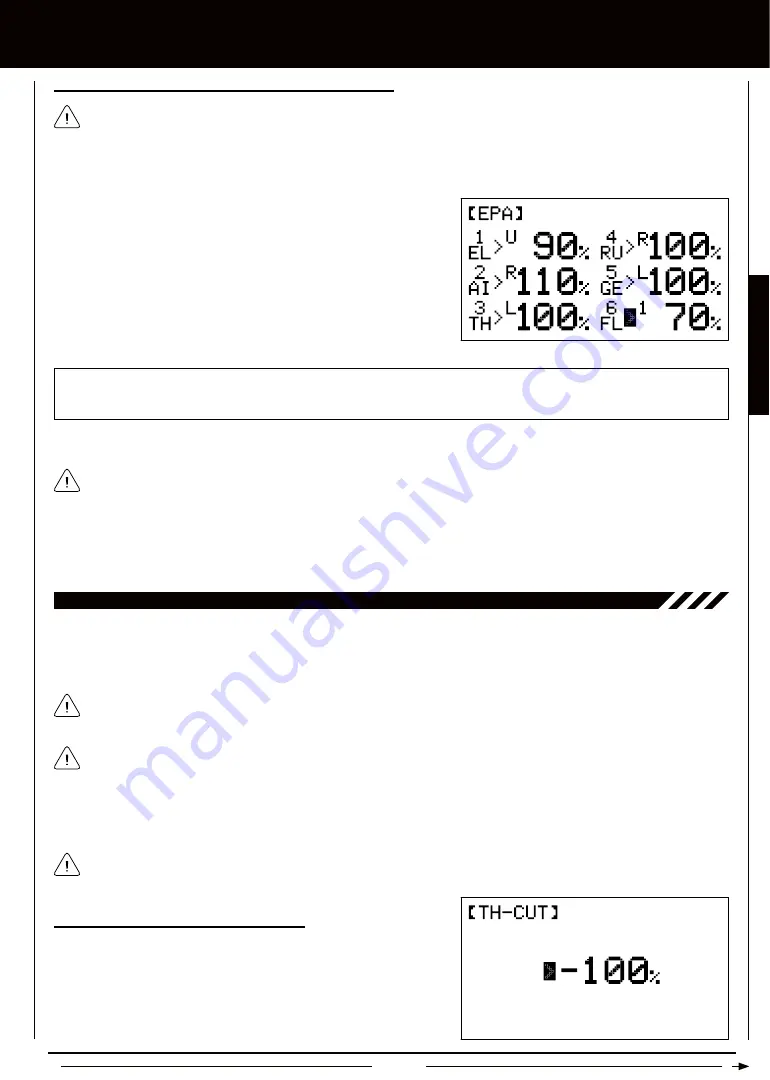

In front of each End Point Adjustment percentage value is a specific icon. To set the End Point Adjustment percentage

value for the desired direction of servo travel, the control stick or switch must be moved in the direction of servo travel you

want to change the End Point Adjustment percentage value for. For example, if you want to change the End Point Adjustment

percentage value for Down elevator, push the elevator control stick forward, then release it. 'D' will be displayed in front of the

Elevator End Point Adjustment percentage value.

3) Press the Navigation Pad

5634

to highlight the channel that you

would like to change the End Point Adjustment percentage value for.

4) Press the INC+/M1 or DEC-/M2 keys to change the End Point Adjust-

ment percentage value.

EPA setting range for the primary flight controls is 0% to 150%. The default setting is 100%. EPA setting range for Flaps is

-150% to 150%. Increasing the End Point Adjustment percentage value increases servo travel and decreasing the End Point

Adjustment percentage value decreases servo travel.

Although the End Point Adjustment function is used to balance and adjust maximum control surface deflection, we suggest

adjusting the control linkages first to try to achieve as close to the desired control surface deflection as possible, then use

the End Point Adjustment function to make final adjustments.

To increase control surface deflection, you can either move the pushrod further out on the servo arm or move the pushrod closer

to the control surface. To decrease control surface deflection, you can either move the pushrod closer to the center of the servo

arm or move the pushrod further away from the control surface.

11.Th-cUT (ThROTTLE cUT)

The Throttle Cut function allows you to set a specific position that the throttle servo will move to when you press the Throttle Cut

button. The Throttle Cut function is primarily used to shut down your engine after flight. You are able to adjust the Throttle

Cut percentage value to ensure that when you press the Throttle Cut button to shut down your engine, the carburetor will close

completely, yet not bind.

Changing the Throttle Cut Percentage Value

1) From the Display screen, press the ENTER key to display the Programming

Menus.

2) Press the Navigation Pad

56

to highlight TH-CUT, then press the

ENTER key to display the TH-CUT menu. The cursor will default to

>-100%.

Before using the Throttle Cut function, make sure that the idle stop screw on your carburetor (if featured) is adjusted to

allow the carburetor barrel to close completely.

When the Throttle Cut function is Activated, throttle control will be disabled.

There are several different methods that can be used to set up your throttle control linkage and the Throttle Cut function. To

prevent any chance of causing your throttle control linkage to bind, possibly resulting in damage to your throttle servo when

you use the Throttle Cut function, we first suggest adjusting the Throttle Low End Point Adjustment percentage value so that

when the throttle control stick is pulled all the way back the carburetor barrel closes completely without binding. Next, increase

the throttle trim (using the throttle trim switch) to adjust your engine's idle. Now change the Throttle Cut percentage value to close

the carburetor barrel without binding when you press the Throttle Cut button.

5) Repeat steps 3 and 4 to change the End Point Adjustment percentage values for the desired remaining channels.

AERO

MODEL

TYPE

Summary of Contents for SD-6G

Page 1: ...Page 1...