K65C/K75C/K95C

4-5

K65C/K75C/K95C

4-5

Fuel supply system

The fuel tank is located on the right-

hand side of the loader rear. An

electrical fuel gauge (4-13/7) in the

operator’s cabin monitors the fuel

level in the tank. The filler neck

(4-6/arrow) is located on the right

side in the cabin access area.

Air filter device

Dry air filter device with safety

cartridge and dust discharge valve.

Lift and tip devices

- Two lift cylinders and

- one tip cylinder

are fed by a double-acting gear-

type pump via a control valve.

All movements of the bucket arm,

the bucket, the attachments and the

quick-change device are controlled

from the operator’s seat by pilot

valves.

The pilot valves provide continuous

speed control from “slow” to “fast”.

Float position

The loader is equipped with a

floating position function which

allows work such as levelling

(grading) to be carried out in a

rough terrain. To use this function,

the hand lever for the working

h y d r a u l i c s ( 4 - 1 2 / 5 ) m u s t b e

pressed beyond its pressure point

into the forward position. The hand

lever remains in this position until

the bucket arm is to be lifted again

by moving the hand lever into the

opposite direction.

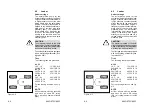

Figure 4-6

Fuel supply system

The fuel tank is located on the right-

hand side of the loader rear. An

electrical fuel gauge (4-13/7) in the

operator’s cabin monitors the fuel

level in the tank. The filler neck

(4-6/arrow) is located on the right

side in the cabin access area.

Air filter device

Dry air filter device with safety

cartridge and dust discharge valve.

Lift and tip devices

- Two lift cylinders and

- one tip cylinder

are fed by a double-acting gear-

type pump via a control valve.

All movements of the bucket arm,

the bucket, the attachments and the

quick-change device are controlled

from the operator’s seat by pilot

valves.

The pilot valves provide continuous

speed control from “slow” to “fast”.

Float position

The loader is equipped with a

floating position function which

allows work such as levelling

(grading) to be carried out in a

rough terrain. To use this function,

the hand lever for the working

h y d r a u l i c s ( 4 - 1 2 / 5 ) m u s t b e

pressed beyond its pressure point

into the forward position. The hand

lever remains in this position until

the bucket arm is to be lifted again

by moving the hand lever into the

opposite direction.

Figure 4-6

Summary of Contents for AL 65

Page 8: ...Safety regulations...

Page 29: ...Signs...

Page 38: ...Technical data...

Page 60: ...Description...

Page 72: ...Operation...

Page 83: ...Attachments...

Page 91: ...Rescue towing lashing lifting by crane...

Page 100: ...Maintenance...

Page 120: ...Malfunctions causes and remedies...

Page 123: ...Protection against theft...

Page 126: ...Appendices...

Page 127: ......

Page 128: ......

Page 131: ......

Page 134: ...K65C K75C K95C K65C K75C K95C B B...

Page 135: ...K65C K75C K95C K65C K75C K95C C C...

Page 136: ...K65C K75C K95C K65C K75C K95C D D...

Page 137: ...K65C K75C K95C K65C K75C K95C E E...

Page 138: ...K65C K75C K95C K65C K75C K95C F F...