33

Adjusting Level Accuracy (Calibration)

Without moving your checking setup, make a mark on the 2 X $ halfway between A1 and A2

(call it C). The laser must be calibrated to bring the beam to the center mark C.

IMPORTANT: Before calibrating, ensure that the instrument housing is level by placing a

small carpenter’s level on top of the unit, parallel with the beam. Do not move the unit: only

adjust the single centerline leg or trivet point until the housing is level.

Do not enter calibration mode or attempt adjustment unless it is planned to change accuracy.

Accuracy adjustment should be performed carefully, by personnel who understand basic

adjustment principles.

If you’ve made changes you do not wish to save, turn the laser off.

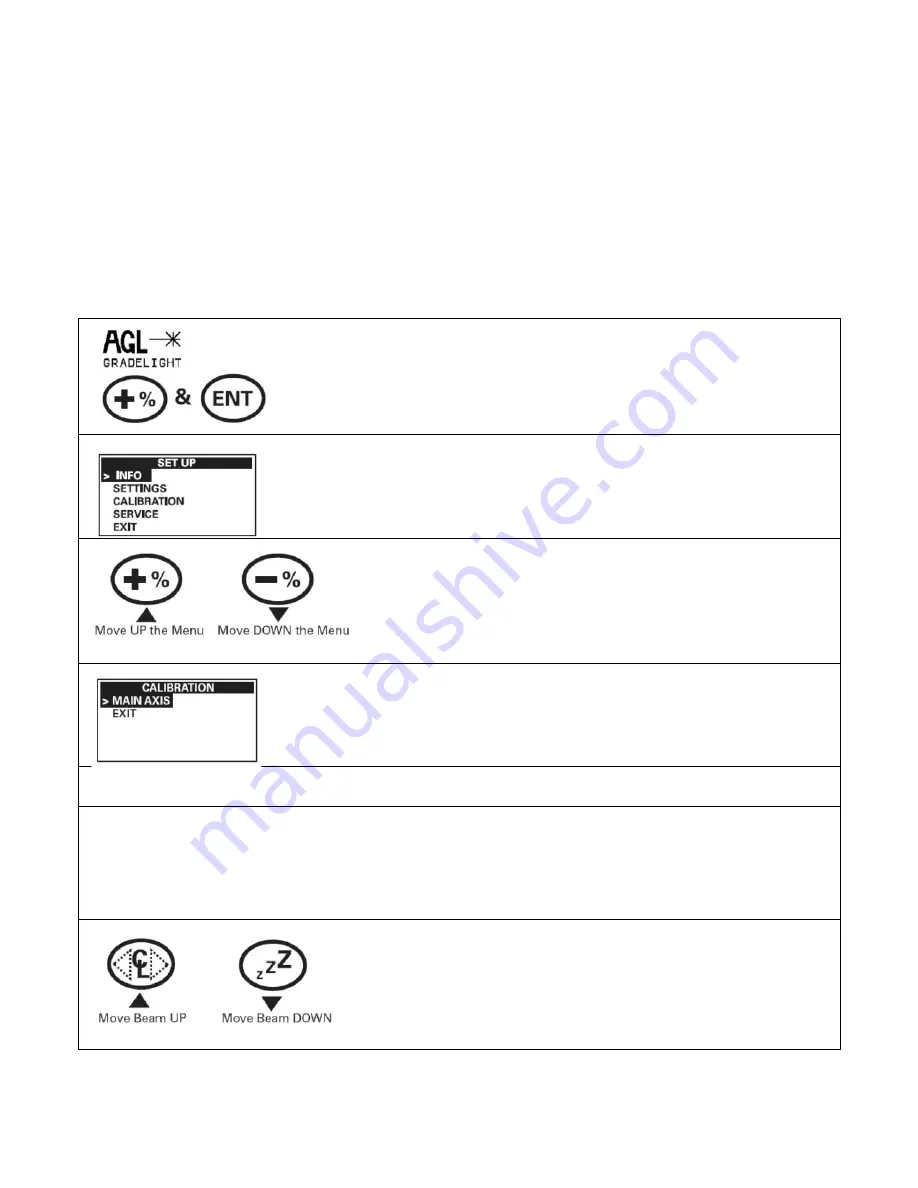

Accessing Calibration through the Set Up Menu

Turn the laser off, and the turn the laser on again.

When the AGL start-up screen is displayed, press the

+

and

ENT

buttons simultaneously. Hold until the Set Up

screen appears (after the Battery Check).

The cursor and highlighted text indicate the active menu

step.

Use the

+

or

–

buttons to move up or down the menu.

Move down to

CALIBRATION

and press

ENT

.

Confirm the step

MAIN AXIS

by pressing

ENT

.

WAIT

The screen will show

WAIT

.

SET

When SET appears, the height of the laser beam can be

adjusted to the center point C.

Do this by using the Remote, so the laser is not disturbed

during adjustment. It will also allow you to stand at stake

A and move the beam until it is at C.

Use the

Center Line

button on the remote to move the

beam up; use the

Standby (ZZZ)

button on the Remote

to move the beam down.

Summary of Contents for GradeLight 3000

Page 1: ...GradeLight 3000 Pipe Laser ...

Page 4: ...3 Laser Overview ...

Page 38: ...37 ...

Page 39: ...38 ...

Page 40: ...39 Printed in USA AM1145 3 10 Specifications subject to change without notice ...