P1512137 R3

13

2.12.2 Electric Motor Safety

Power Source

• Electric motors and controls shall be installed and serviced by

a qualified electrician and must meet all local codes and

standards.

• A magnetic starter should be used to protect your motor.

• You must have a manual reset button.

• Reset and motor starting controls must be located so that the

operator has full view of the entire operation.

• Locate main power disconnect switch within reach from

ground level to permit ready access in case of an emergency.

• Motor must be properly grounded.

• Guards must be in place and secure.

• Ensure electrical wiring and cords remain in good condition;

replace if necessary.

• Use a totally enclosed electric motor if operating in

extremely dusty conditions.

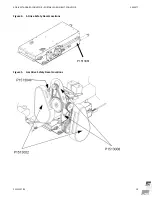

S E R V I C E D I S C O N N E C T

ON

OFF

Lockout

• The main power disconnect switch should be in the locked position during shutdown or

whenever maintenance is performed.

• If reset is required, disconnect all power

before

resetting motor.

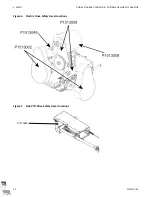

2.12.3 PTO Driveline Safety

Drive

• Keep body, hair, and clothing away from rotating PTO

driveline.

• Make certain the driveline shields telescope and rotate freely

on driveline before attaching.

• Make certain the driveline is securely attached at both ends.

• Do not operate conveyor unless all driveline, tractor, and

equipment shields are in place and in good working order.

• Do not exceed the specified operating speed.

• Keep universal joint angles small and equal. Do not exceed

maximum recommended length for PTO driveline.

• Engage tractor park brake and/or chock wheels.

Lockout

• Position all controls in neutral, shut off tractor’s engine, and remove key from tractor.

• If removing key is impossible, remove PTO driveline from tractor.

S-DRIVE STANDARD CONVEYOR – PORTABLE GRAIN BELT CONVEYOR