Chapter 4 Maintenance Procedures

91

USG-CUS-059 Rev05

MassARRAY® Nanodispenser RS1000 v2.1 User Guide

For Research Use Only. Not for use in diagnostic procedures.

4.4 Daily maintenance

These maintenance procedures should be performed each day before starting

dispensing:

•

Clean the pins (below)

•

Drain and fill the ultrasonic wash supply bottle, page 94

•

Flush the calibrant reservoir, page 97

•

•

Drain the waste tank, page 102

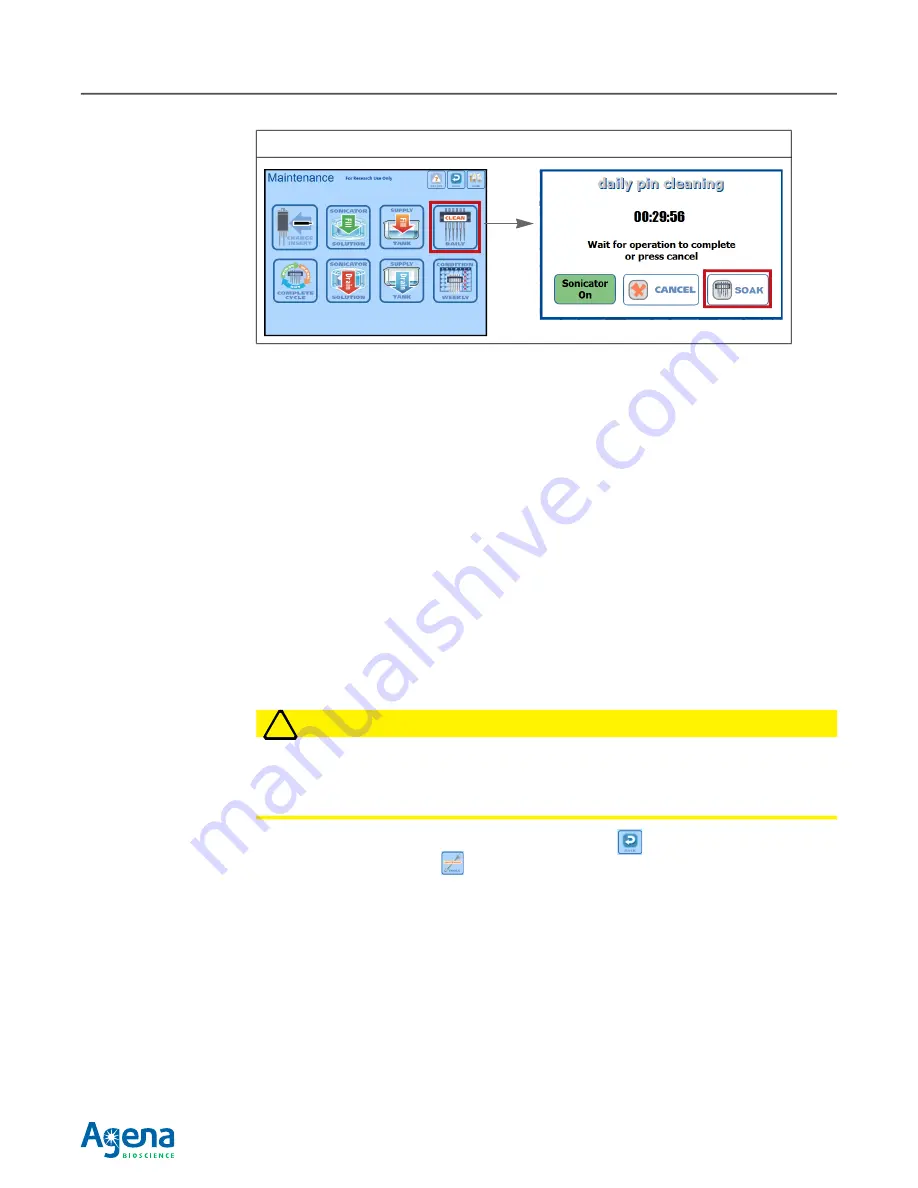

Clean the pins

Before dispensing to SpectroCHIP Arrays, the pins must be cleaned by soaking the pins

in 100% ethanol. Pin cleaning is usually required only once at the beginning of each day

of use. The cleaning process takes approximately 30 minutes.

To clean the pins:

WARNING

!

WARNING!

You will be handling ethanol in this procedure. For safe handling procedures, refer

to the MSDS provided by your ethanol supplier. At a minimum: 1) wear protective clothing

(laboratory gloves, eye protection, and laboratory coat), 2) have adequate laboratory ventilation,

3) keep away from ignition sources, 4) and have proper fire extinguishing devices/solutions readily

accessible.

1.

Go to the Maintenance screen (tap the Back button

on any screen and tap the

MAINTENANCE

button

on the Main Menu).

2.

Tap

SONICATOR SOLUTION Drain

The ultrasonic wash begins draining and an on-screen message displays the time

remaining for the operation. Wait for draining to finish.

Figure 4.1 Starting the Pin Soak