41

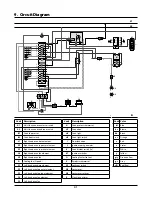

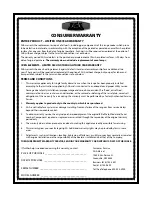

9. Circuit Diagram

6

P6

5 P5

4

P4

7 P7

8 P8

2

P2

1

P1

3 P3

a

b

e

f

c

d

1

2

v

32

31

21

22

24

14

12

1 2

1

2

P2

P1

A1

A2/B1 B2

6

P6

5 P5

4

P4

7 P7

8 P8

2

P2

1

P1

3 P3

11

or

gy

b

gy

w

y

or

r

br

w

b

gy

w

y

or

r

r

r

br

br

b

v

bk

b

r

bk

v

br

v

bk

r

r

or

w

bk

br

w

or

v gy

gy w r

r

or

or

v

r

v

br

br

v

br

or

or

or

v

v

v

b

w

w

r

v

r

br

bk

bk

r

bk bk

bk

w

b

bk

bk

br

v

br

br

br

N

L1

L2

A1

A2

B1

B2

K

G

H3

H2

H2

J

M

O

P

D

Q2

R

I

Q1

H1

Q3

C1

C2

C3

C4

C5

F1

F2

F3

F4

F5

Code Description

A1

Multi-function oven master switch

A2

Multi-function oven drone switch

B1

Oven thermostat

B2

Oven front switch

C1

Right-hand oven base element

C2

Right-hand oven top outer element

C3

Right-hand oven top inner element

C4

Right-hand oven fan element

C5

Right-hand oven fan

D

Cooling fan (2 speed)

F1

Left-hand oven base element

F2

Left-hand oven top outer element

F3

Left-hand oven top inner element

F4

Left-hand oven fan element

F5

Left-hand oven fan

Code Color

bl

Blue

br

Brown

bk

Black

or

Orange

r

Red

v

Violet

w

White

y

Yellow

g/y

Green/yellow

gr

Grey

r(f)

Red (flag)

Code Description

G

Oven protect thermostat

H1

Oven neon

H2

Oven light

H3

Oven light switch

I

Door lock neon

J

Ignition spark generator

K

Oven divider switch (In)

M

Ignition switches

O

Cooling fan fail cut-out

P

Pyrolytic thermostat

Q1

Lock cam switch

Q2

Lock motor

Q3

Lock motor resistor

R

Clock / oven timer

Summary of Contents for Professional 90 Dual Fuel

Page 1: ...90 Dual Fuel User Guide Installation Service Instructions U110246 01 Professional ...

Page 45: ...43 ...

Page 46: ...44 ...