Heat recovery units with refrigeration circuit -

URX_CF

-

27

Selection and installation manual

GB

Maintenance of the unit

CAUTION!

During the maintenance phase, wear

proper individual protection devices

(IPD)

•

Before performing maintenance

and/or cleaning operations on

the unit, make sure the unit is

disconnected from the power supply

and that it can not be turned back

on without the knowledge of the

person performing maintenance, and

that the heat exchanger coils are not

working.

•

During maintenance the weight

of the inspection panelling could

hinder the work

The URX_CF series recovery units

have been designed to require

very little maintenance and to make

every operation easy. Some simple

pieces of advice follow for the proper

maintenance of the unit.

Filters

Filter cleaning is imperative to

maintain high air quality in the room.

The synthetic filters installed in the

URX_CF unit can be regenerated with

compressed air or can be washed with

cold water. To disassemble the filters:

• remove the inspection panel with

knobs;

• remove the filters;

• clean the filters;

• replace all parts in reverse order.

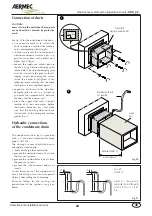

Condensate

drain pan

Dirt can hoard up in the condensate

d r a i n p a n . Yo u a r e t h e r e f o r e

recommended to clean the pan

regularly and check that the discharge

pipe is not clogged.

To remove the condensate drain pan of

the heat recovery unit:

• remove all bottom panels;

• disassemble the cross bar;

• disconnect the pan from the

condensate drain pipes;

• disassemble the pan supporting

brackets;

• clean the pan;

• replace all parts in reverse order.

In order to access the condensate drain

pan on the coil module, detach the

module from the unit and disassemble it.

Heat recovery

The heat recovery unit can be cleaned

with a jet of compressed air or cold

water. To disassemble the heat recovery

unit:

• remove the condensate drain pan;

• remove the heat recovery unit

supporting brackets;

• clean the heat recovery unit;

• replace all parts in reverse order.

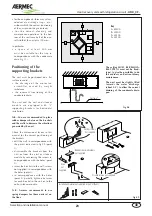

Motor ventilating assembly

The motor ventilating assembly needs to

be checked to see how clean the rotor

is, whether there is corrosion or damage,

and whether there are abnormal noises.

If necessary disassemble the motor fan

assembly as follows:

• remove all inspection panels;

• disconnect the power supply cable;

• unscrew the four screws that hold each

of the motor fan assemblies to the frame;

• check the motor fan assemblies and

replace them if necessary;

• replace all parts in reverse order.

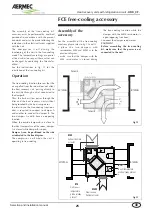

REFRIGERANT LOAD

SIZES URX_CF

07

10

15

21

33

kg

Consult AERMEC Technical Departiment

Checks during

operation

The air flow rate values must not be

lower than 15% of the nominal values

indicated in the technical specifications

table.

If an electrical resistance is present,

check the cut-in by measuring its

electrical absorption.

Requirements of gas

R410A

The circuit chillers that work on R410a

cooling gas require particular attention

during assembly and maintenance, to prevent

operating faults.

Therefore it is necessary to:

- Avoid refilling with oil different from

the one specified and already used in

the compressor.

- If there are gas leaks causing the unit

to be even partially empty, do not

refill with refrigerant, but empty the

unit completely and refill it with the

foreseen amount.

-

In the event of replacement of one of

the refrigerating circuit parts, do not

leave the circuit open for more than

15 minutes.

-

In particular, in the event of

replacing the compressor, complete

the installation within the above-

mentioned time after the rubber plugs

have been removed.

- When empty, do not switch on the

compressor; do not compress the air

within the compressor.

Summary of Contents for URX CF

Page 2: ......

Page 31: ...NOTE ...

Page 32: ...NOTE ...

Page 33: ...NOTE ...

Page 34: ...NOTE ...

Page 35: ......