22. HYDRAULIC

CIRCUIT

The NRL consists ofTWO CIRCUITS both

fitted with:

−

Evaporators 1 x circuit

−

Water filter 1 per circuit (supplied)

supplied with log and victaulic gaskets

−

Desuperheaters

(2 per circuit in parallel mode)

without filter

−

Water inlet probe SIW

−

Water outlet probe SUW

NB:

The water outlet probe (WOP) with its

trap is free, near the electrical box,

remember to insert it in the collector

of the outlet hydraulic parallel, using a

sleeve of ½ inch.

22.1.

EXTERNAL HYDRAULIC CIRCUIT

RECOMMENDED

The selection and installation of components

outside the NRL should be carried out by

the installer, who should work according

to the technical code of practice and in

compliance with the legislation in force in

the country of destination (MD 329/2004).

Before connecting the pipes make sure that

they do not contain stones, sand, rust, slag

or any foreign bodies that may damage the

system. It is necessary to make a by-pass to

the unit to be able to carry out the cleaning

of the pipes without having to disconnect

the machine. The connection pipes must be

properly supported so as not to burden the

unit with their weight.

On the water circuit, it is advisable to install

the following instruments, if not foreseen in

the version you have:

1. Two pressure gauges of suitable size

(input and output section).

2. Two antivibrating couplings (input and

output section).

3. Two shut-off valves (normal input section,

output section calibrating valve).

4. Two thermometers (input and output

section).

5. Expansion

tanks

6. Pump

7. Accumulation

8. Flow

switch

9. Safety

valve

10. Charging unit

11. Chiller drain tap in the tube output

evaporator (for standard version)

NB:

In case of version with pumping unit,

without standby pump,

it is recommended to install

undirectional valves to the delivery of

each module.

So water reflow is avoided

in the circuit of the pump/s

from the other circuit.

For NRL 2250 model with pumping unit, it

is recommended the installation, to the

delivery of the module 1250, of a capacity

balance valve, to balance the capacities

between the two evaporators (module

1000 and 1250).

It is necessary, that the water flow rate to

the chiller unit complies with the values

reported in the performance tables.

The systems loaded with anti-freeze or

specific regulations, need the water

backflow system.

Special supply/recovery water, is carried

out with appropriate treatment systems.

22.2. SYSTEM

LOAD

−

Before starting the load, check that the

system drain tap is closed.

−

Open all the drain valves of the system

and of the related terminals.

−

Open the shut-off devices of the system.

−

Start the filling by slowly opening the

water system load cock placed outside

the machine.

−

When water begins to flow from the

terminal vent valves, close them and

continue loading up to read on the

gauge the value of 1.5 bar.

The system is loaded at a pressure between

1 and 2 bar.

It is advisable to repeat this operation

once the machine has worked for some

hours and to periodically check the system

pressure, restoring if it drops below 1 bar.

Check the hydraulic seal of the joints.

22.3. EMPTYING THE SYSTEM

−

Before starting to drain the system, turn

"off" the unit

−

Check that the water system load/

restore tap is closed

−

Open the drain tap outside the machine

and all the vent valves of the system

and the corresponding terminals.

−

In case of prolonged shut-down of the

unit during winter (if not added with

glycol) or for other inconveniences,

drain the chiller hydraulic circuit by the

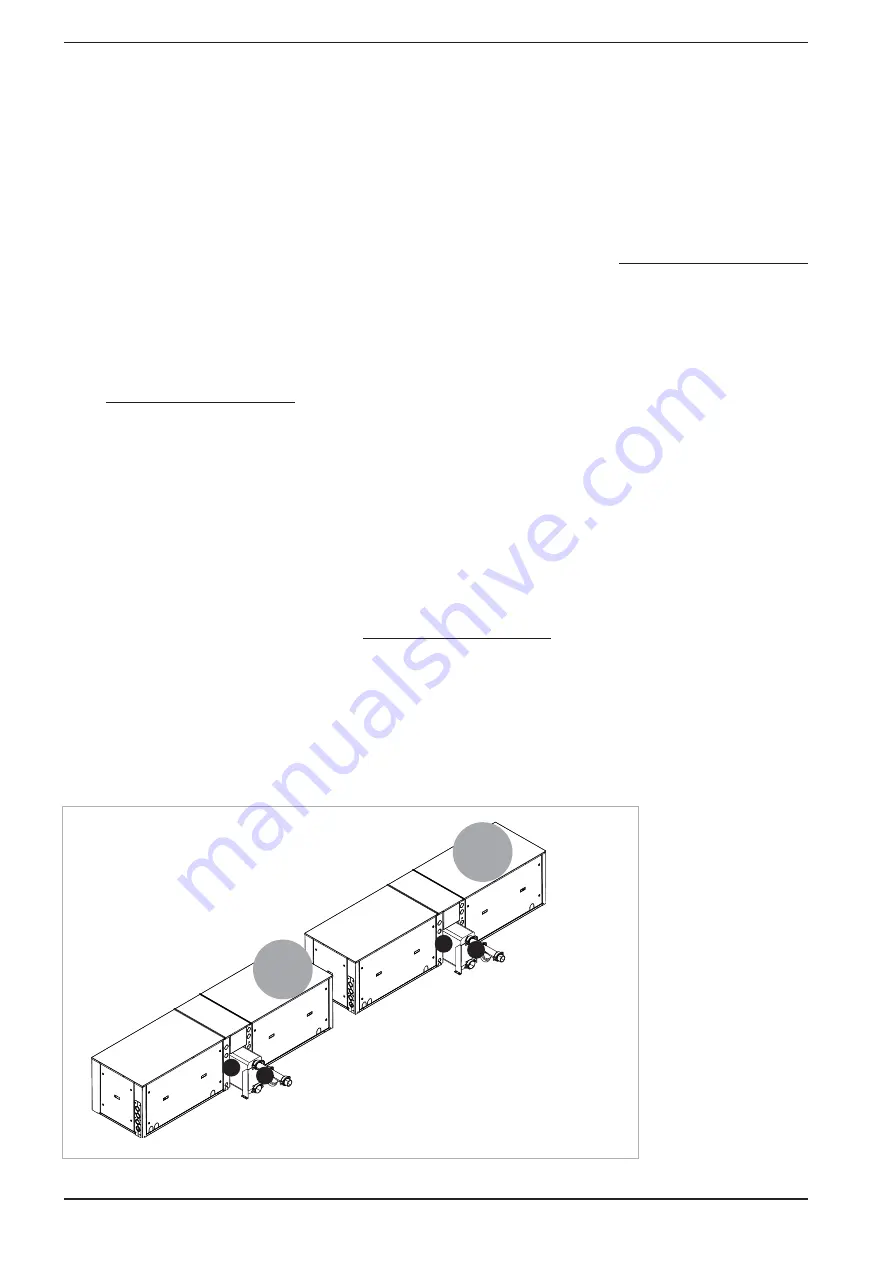

corresponding knobs (see

fi

g.1 and

fi

g.2)

If the system uses glycol, this liquid should

not be drained to the environment because

it is a pollutant. It must be collected and, if

possible, reused.

KEY

1 Evaporator (plate-type exchangers)

2 Water filter 1 x circuit SUPPLIED

3 Flow

switch

NB

In addition to the filter, victaulic and

welded pipes are provided

The drawings represent only examples

of the machine hydraulic circuit

Circuit 1°

Circuit 2°

1

1

2

2

40

INRLPY. 02.10 4086916_01

Summary of Contents for NRL

Page 2: ......