38

8.2.3 - Expansion Tank

If a water heater is installed in a

closed water supply system, such

as one having a backflow preventer

in the cold water supply line, means

shall be provided to control thermal

expansion. Contact the water supplier

or local plumbing inspector on how to

control this situation.

Install an expansion tank. Ensure

the expansion tank is properly sized

for the water volume (See Section

18, header “Content of water”) and

the system volume, temperature and

pressure.

CAUTION!!!

Undersized

expansion tanks will cause

system water to be lost

through the relief valve

The expansion tank must be located

as shown in Figure 8-5 or as per

recognized design methods. Refer

to the expansion tank manufacturer

instructions for additional installation

details.

8.2.4 - Circulator pump

This water heater must be fitted with a

circulator pump for domestic potable

hot water. To size and install the pump

follow section 8.4.

8.2.5 - Sizing water

system

Size the piping and system

components required in the water

system, using recognized design

methods.

8.2.6 - Anti-legionella

This water heater is not protected

against the proliferation of the

Legionella bacteria. If you don’t

install any Anti-legionella external

system, you have to keep the water

temperature, at least at 140°F (60°C).

This temperature will prevent the

proliferation of the legionella bacteria.

WARNING!!!

Your domestic

hot water system must be

protected against legionella

bacteria. Failure to comply with

this provision can result in

severe personal injury or death.

8.4 - How to install

the circulator pump

This water heater must be fitted with a

circulator pump for domestic potable

hot water. Size the pump follow figure

8-3 in function of the model and in

function of the water hardness.

CAUTION!!!

undersize the

circulator pump could damage

the water heater due to scale

formation and corrosion.

To electrically connect the pump

(Local pump) follow Figure 10-2.

A field supplied pump relay must be

installed if the pump current draw is

greater than 3 amps.

If the pump have an interax of 6” 1/2,

you can install it between flanges “C”

and “D” of Figure 8-4. If the pump

have an interax of 8” 1/2, replace

pipe “D” with the factory supplied pipe

“F” and apply seal adapter “G” with

gasket “H” (both factory supplied) as

shown in figure 8-4.

For the electrical connection, proceed

as follows (refer to Figure 10-2):

1. remove the heater casing following

the instructions given in section 17.2

and open the junction box cover;

2. use a three conductor cable with

a minimum cross section of #18

AWG between the water heater

and the pump;

3. connect the cable leads to the

“113”, “114” and “Ground”

terminals as shown in Figure 10-

2.

4. connect the other side of the

cable to the pump as shown in

the instruction supplied with the

pump.

8 - INSTALLATION - Water connections

8.3 - Scalding

This water heater can deliver scalding

temperature water at any faucet in the

system.

Be careful whenever using hot water

to avoid scalding injury.

Certain appliances such as

dishwashers and washing machines

may require increased temperature

water.

By setting the water temperature

control on this water heater to obtain

the increased temperature water

required by these appliances, you

may create the potential for scald

injury.

To protect against injury, you should

install a mixing valve in the water

system.

This valve will reduce point of

discharge temperature by mixing cold

and hot water in branch supply lines.

Such valves are available from the

local plumbing supplier.

Figure 8-2 details the relationship

of water temperature and time with

regard to scald injury and may be

used as a guide in determining the

safest water temperature for your

applications.

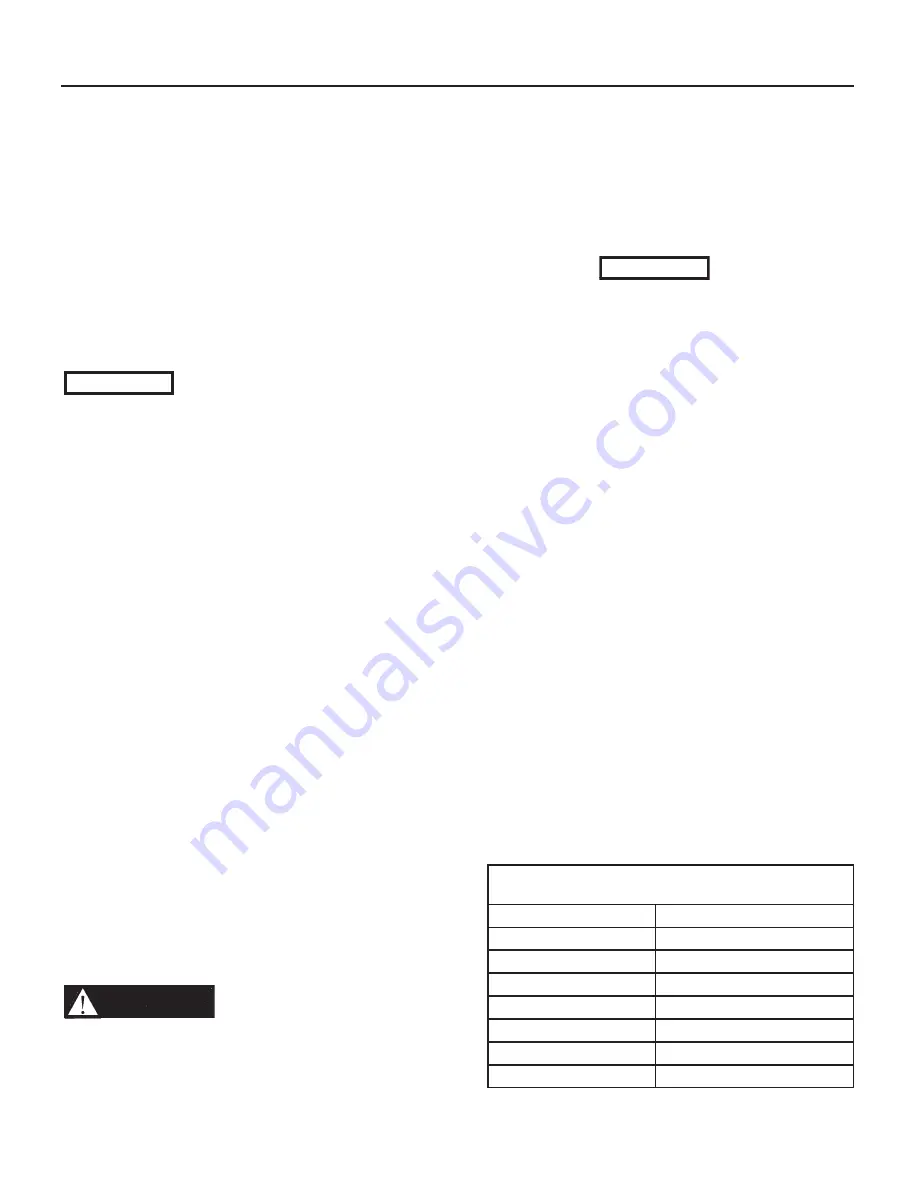

APPROXIMATE TIME / TEMPERATURE

RELATIONSHIPS IN SCALDS

120°F (49°C)

More than 5 minutes

125°F (51°C)

1,5 to 2 minutes

130°F (54°C)

About 30 seconds

135°F (57°C)

About 10 seconds

140°F (60°C)

Less than 5 seconds

145°F (63°C)

Less than 3 seconds

150°F (65°C)

About 1,5 seconds

155°F (68°C)

About 1 second

Figure 8-2 Time / temperature scalds

Summary of Contents for Esteem 399

Page 3: ...3 SAFETY INSTRUCTIONS ...

Page 5: ...5 SAFETY INSTRUCTIONS ...

Page 112: ...112 17 MAINTENANCE ...

Page 116: ...116 19 SPARE PARTS Spare parts ...

Page 135: ......