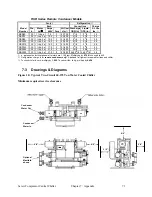

Screw Compressor Central Chiller

Chapter 7: Appendix

73

RSR Series Remote Condenser Models

Fan(s)

Refrigeration

d

Each

Connections

Charge

Model

Dia.

Motor

Amps

Air flow Discharge Liquid

R-134a

Number

In.

hp

c

460V Fans cfm

e

ODS(in.) ODS(in.)

lbs.

d

RSR60

30

1

½

hp ø

7.0

2

20,700

21

/

8

21

/

8

19

RSR75

30 1

½

hp 3 ø 10.5

3

32,900

21

/

8

21

/

8

24

RSR90

30 1

½

hp 3 ø 10.5

3

31,800

21

/

8

21

/

8

29

RSR100

30 1

½

hp 3 ø 14.0

4

43,900

21

/

8

21

/

8

29

RSR115

30 1

½

hp 3 ø 14.0

4

41,500

21

/

8

21

/

8

36

RSR145

30 1

½

hp 3 ø 17.5

5

51,800

25

/

8

25

/

8

43

RSR165

30 1

½

hp 3 ø 21.0

6

65,800

25

/

8

25

/

8

50

RSR195

30 1

½

hp 3 ø 21.0

8

87,800

2 @ 25

/

8 2 @ 25

/

8

58

c

ø represents electrical phase; all motors are 1,140 rpm. Multiply hp by

0.746

to convert to

kW

.

d

Refrigeration charge is for

remote condenser only!

Additional refrigerant is requied for lines and chiller.

e

To convert cfm to

cmh

, multiply by

1.699

. To convert lbs. to

Kg

, multiply by

0.454.

7-3 Drawings & Diagrams

Figure 10: Typical Two-Circuit 60-195 Ton Water Cooled Chiller

Minimum required service clearance

Condenser

Water Out

Condenser

Water In

Optional

Manifold

shown

6’-0”

6’-0”

3’-0”

3’-0”

4’-0”