Call StormTech at

860.529.8188

or

888.892.2694

or visit our website at

www.stormtech.com

for technical and product information.

31

12.0 Inspection and Maintenance

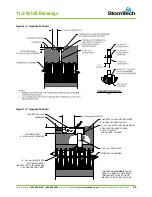

Looking down the Isolator Row

A typical JetVac truck (This is not a StormTech product.)

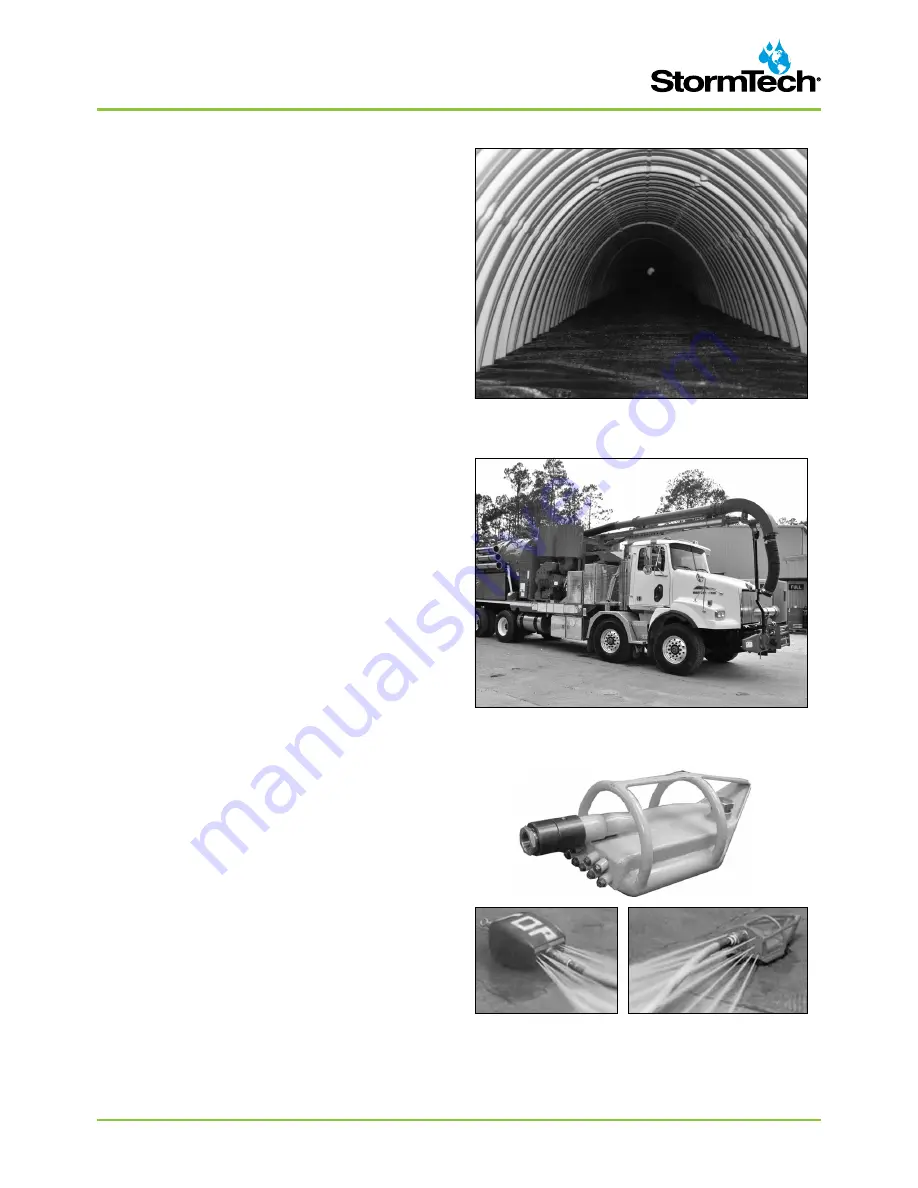

Examples of culvert cleaning nozzles appropriate for

Isolator Row maintenance. (These are not StormTech

products).

12.1 ISOLATOR ROW INSPECTION

Regular inspection and maintenance are essential

to assure a properly functioning stormwater system.

Inspection is easily accomplished through the manhole or

optional inspection ports of an Isolator Row. Please follow

local and OSHA rules for a confined space entry.

Inspection ports can allow inspection to be accomplished

completely from the surface without the need for a

confined space entry. Inspection ports provide visual

access to the system with the use of a flashlight. A stadia

rod may be inserted to determine the depth of sediment.

If upon visual inspection it is found that sediment has

accumulated to an average depth exceeding 3” (76 mm),

cleanout is required.

A StormTech Isolator Row should initially be inspected

immediately after completion of the site’s construction.

While every effort should be made to prevent sediment

from entering the system during construction, it is during

this time that excess amounts of sediments are most

likely to enter any stormwater system. Inspection and

maintenance, if necessary, should be performed prior

to passing responsibility over to the site’s owner. Once

in normal service, a StormTech Isolator Row should be

inspected bi-annually until an understanding of the sites

characteristics is developed. The site’s maintenance

manager can then revise the inspection schedule based

on experience or local requirements.

12.2 ISOLATOR ROW MAINTENANCE

JetVac maintenance is recommended if sediment has

been collected to an average depth of 3” (76 mm) inside

the Isolator Row. More frequent maintenance may be

required to maintain minimum flow rates through the

Isolator Row. The JetVac process utilizes a high pressure

water nozzle to propel itself down the Isolator Row while

scouring and suspending sediments. As the nozzle is

retrieved, a wave of suspended sediments is flushed

back into the manhole for vacuuming. Most sewer and

pipe maintenance companies have vacuum/ JetVac

combination vehicles. Fixed nozzles designed for culverts

or large diameter pipe cleaning are preferable. Rear facing

jets with an effective spread of at least 45” (1143 mm)

are best. The JetVac process shall only be performed

on StormTech Rows that have AASHTO class 1 woven

geotextile over the foundation stone (ADS 315ST or equal).

Summary of Contents for StormTech DC-780

Page 2: ...An company TOOL 2 0 DESIGN ...

Page 39: ......