Call StormTech at

860.529.8188

or

888.892.2694

or visit our website at

www.stormtech.com

for technical and product information.

22

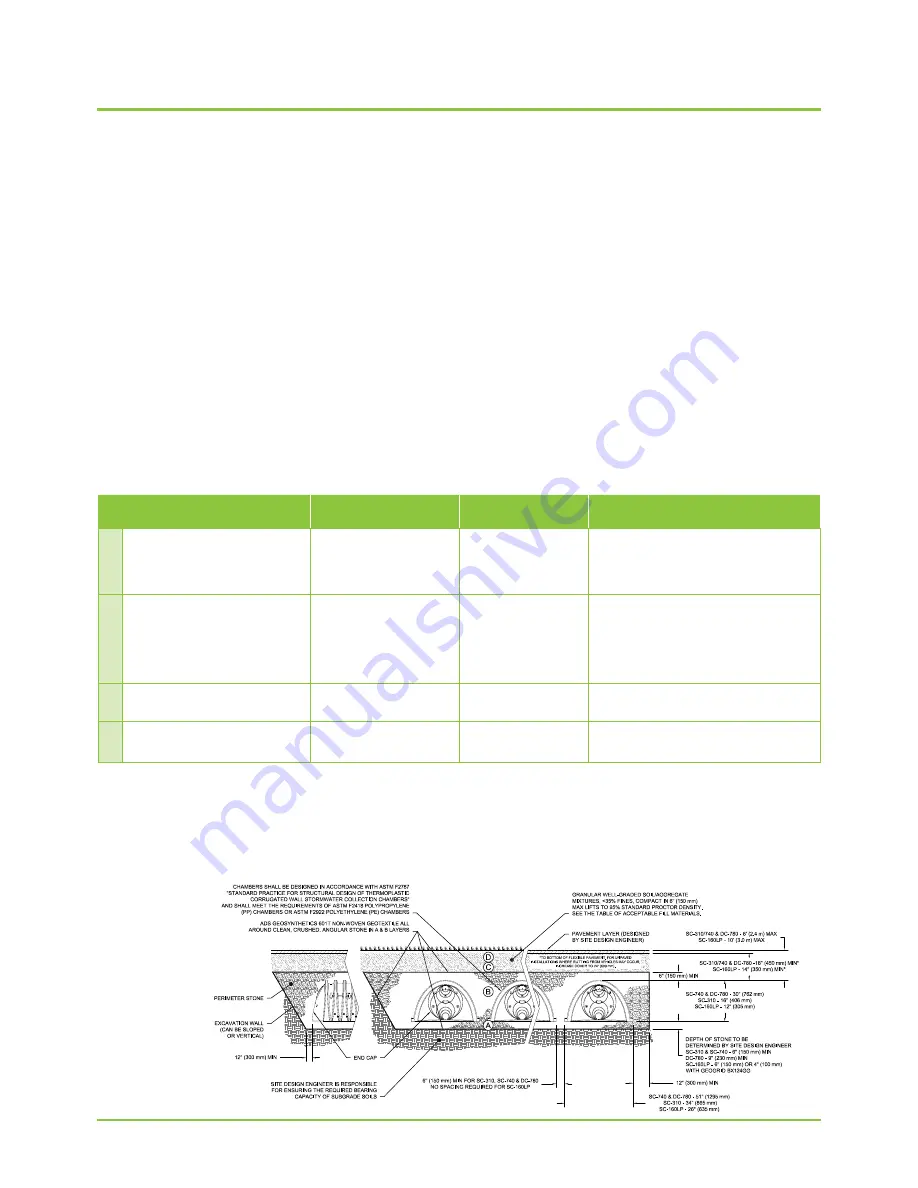

6.0 Required Materials/Row Separation

6.1 CHAMBER ROW SEPARATION

StormTech SC-740, SC-310 and DC-780 chambers must

be specified with a minimum 6” (150 mm) space between

the feet of adjacent parallel chamber rows. No spacing is

required between the SC-160LP chambers. Increasing the

space between rows is acceptable. This will increase the

storage volume due to additional stone voids.

6.2 STONE SURROUNDING CHAMBERS

Refer to

Table 8

for acceptable stone materials.

StormTech requires clean, crushed, angular stone below,

between and above chambers as shown in

Figure 6

.

Acceptable gradations are listed in

Table 8

. Subrounded

and rounded stone are not acceptable.

6.3 GEOTEXTILE SEPARATION REQUIREMENT

A non-woven geotextile that meets AASHTO M288

Class 2 Separation requirements must be applied as a

separation layer to prevent soil intrusion into the clean,

crushed, angular stone as shown in

Figure 6

. The

geotextile is required between the clean, crushed, angular

stone and the subgrade soils, the excavation’s sidewalls

and the fill materials. The geotextile should completely

envelope the clean, crushed, angular stone. Overlap

adjacent geotextile rolls per AASHTO M288 separation

guidelines. Contact StormTech for a list of acceptable

geotextiles.

6.4 FILL ABOVE CHAMBERS

Refer to

Table 8

and

Figure 6

for acceptable fill material

above the 6” (150 mm) of clean, crushed, angular stone.

Minimum and maximum fill requirements for the SC-

160LP, SC-740, SC-310 and DC-780 chambers are shown

in

Figure 6

below. StormTech requires a minimum of 24”

(600 mm) of fill in non-paved installations where rutting

from vehicles may occur.

Table 8

provides details on

soil class and compaction requirements for suitable fill

materials.

Material Location

Description

AASHTO Material

Classifications

Compaction / Density Requirement

D

Final Fill:

Fill material for layer ‘D’ starts

from the top of the ‘C’ layer to the bottom

of the flexible pavement to unpaved

finished grade above. Note that pavement

subbase may be part of the ‘D’ layer.

Any soil/rock material, native

soils, or per Engineer’s plans.

Check plans for pavement

subgrade requirements

N/A

Prepare per site design Engineer’s plans. Paved

installations may have stringent material and

preparation requirements.

C

I

nitial Fill:

Fill material for layer ’C’ starts

form the top of the embedment stone

(‘B’ Layer) to 18” (450 mm) above the

top of the chamber. Note that pavement

subbase may be a part of the ‘C’ layer.

Granular well-graded soil/

aggregate mixtures, <35% fines

or processed aggregate

Most pavement subbase

materials can be used in lieu of

this layer

AASHTO M145

1

A-1, A-2-4, A-3

OR

AASHTO M43

1

3, 357, 4, 467, 5, 56, 57, 6,

67, 68, 7, 78, 8, 89, 9, 10

Begin Compactions after 12” (300 mm) of material

over the chambers is reached. Compact additional

layers in 6” (150 mm) max lifts to a min. 95% proctor

density for well graded material and 95% relative

Density for processed aggregate materials. Roller

gross vehicle weight not to exceed 12,000 lbs (53

kN). Dynamic force not to exceed 20,000 lbs (89 kN)

b

Embedment stone

: Fill surrounding the

chambers from the foundation stone (‘A’

layer) to the ‘C’ layer above

Clean, crushed, angular stone,

nominal size distribution

between ¾-2 inch (20-50 mm)

AASHTO M145

1

3, 357, 4, 467, 5, 56, 57

No compaction required.

A

Foundation stone:

Fill below chambers

from the subgrade up to the foot (bottom)

of the chamber.

Clean, crushed, angular stone,

nominal size distribution

between ¾-2 inch (20-50 mm)

AASHTO M145

1

3, 357, 4, 467, 5, 56, 57

Plate compact or roll to achieve a flat surface.

2 3

Table 8 – Acceptable Fill Materials

Figure 6 – Fill Material Locations

Please Note:

1. The listed AASHTO designations are for gradations only. The stone must also be clean, crushed, angular. For example, a specification for #4 Stone

would state: “clean, crushed, angular No. 4 (AASHTO M43) Stone”.

2. StormTech compaction requirements are met for ‘A’ location materials when placed and compacted in 6” (150 mm) (MAX) Lifts using two full

coverages with a vibratory compactor.

3. Where infiltration surfaces may be compromised by compaction, for standard design load conditions, a flat surface may be achieved by raking of

dragging without compaction equipment. For special load designs, contact StormTech for compaction requirements.

Once layer ‘C’ is

placed any soil/

material can be

placed in layer

‘D’ up to the

finished grade.

Most pavement

subbase soils can

be used to replace

the materials

requirements of

layer ‘C’ or ‘D’ at the

design engineer’s

discretion.

Summary of Contents for StormTech DC-780

Page 2: ...An company TOOL 2 0 DESIGN ...

Page 39: ......