Call StormTech at

860.529.8188

or

888.892.2694

or visit our website at

www.stormtech.com

for technical and product information.

14

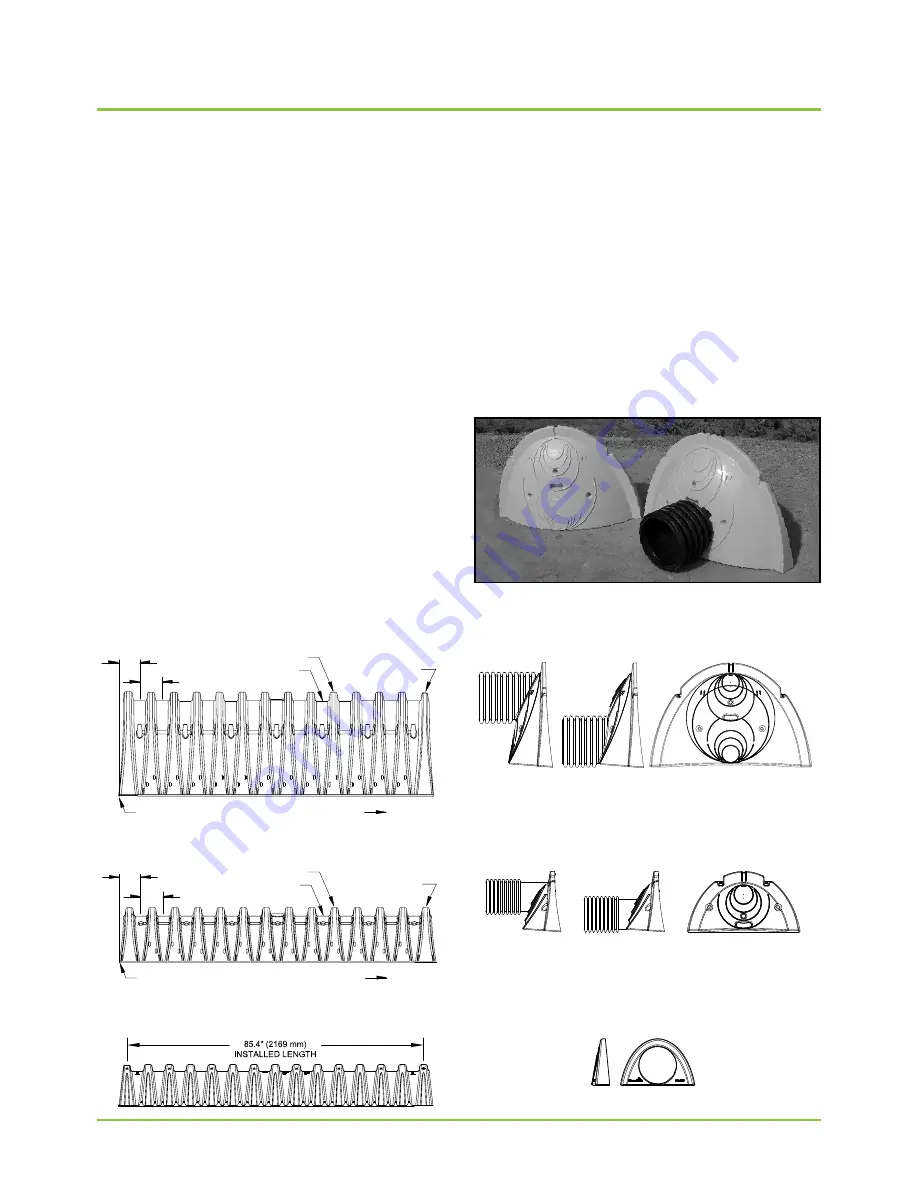

5.8" (147 mm)

6.5" (165 mm) 12 PL

CREST 14 PL

VALLEY 13 PL

OVERLAP NEXT

CHAMBER HERE

START END

BUILD ROW IN THIS DIRECTION

5.8"

6.5" (165 mm) 12 PL

CREST 14 PL

VALLEY 13 PL

OVERLAP NEXT

CHAMBER HERE

START END

BUILD ROW IN THIS DIRECTION

(147 mm)

SC-310 CHAMBER FABRICATED END CAP (TOP AND BOTTOM FEED)

PIPES SIZES RANGE FROM 6" (150 mm) TO 12" (300 mm)

(INVERTS VARY WITH PIPE SIZE)

SC-740/DC-780 CHAMBER FABRICATED END CAP (TOP AND BOTTOM FEED)

PIPES SIZES RANGE FROM 6" (150 mm) TO 24" (600 mm)

(INVERTS VARY WITH PIPE SIZE)

SC-160LP CHAMBER END CAP

2.0 Product Information

2.5 STORMTECH CHAMBERS

StormTech chamber systems have unique features to

improve site optimization and reduce product waste.

The SC-160LP, SC-310, SC-740, and DC-780 chambers

can be cut at the job site in approximately 6.5” (165 mm)

increments to shorten a chamber’s length. Designing and

constructing chamber rows around site obstacles is easily

accomplished by including specific cutting instructions

or a well placed “cut to fit” note on the design plans. The

last chamber of a row can be cut in any of its corrugation’s

valleys. An end cap placed into the trimmed corrugation’s

crest completes the row. The trimmed-off piece of a

StormTech chamber may then be used to start the next

row. See

Figure 4.

To assist the contractor, StormTech chambers are molded

with simple assembly instructions and arrows that indicate

the direction in which to build rows. Rows are formed by

overlapping the next chamber’s “Start End” corrugation

with the previously laid chamber’s end corrugation. Two

people can safely and efficiently form rows of chambers

without complicated connectors, special tools or heavy

equipment.

Product Specifications: 2.2, 2.4, 2.5, 2.9 and 3.2.

SC-740 Chamber

SC-740 / DC-780 End Cap

SC-310 Chamber

SC-310 End Cap

SC-160LP Chamber

SC-160LP End Cap

2.6 STORMTECH END CAPS

The StormTech end cap has features which make the

chamber system simple to design, easy to build and more

versatile than other products. StormTech end caps can be

easily secured within any corrugation’s crest. A molded-

in handle makes attaching the end cap a oneperson

operation. Tools or fasteners are not required.

StormTech end caps are required at each end of a

chamber row to prevent stone intrusion (two per row). The

SC-740 and DC-780 end caps will accept up to a 24” (600

mm) HDPE inlet pipe. The SC-310 end cap will accept

up to a 12” (300 mm) HDPE inlet pipe. The SC-160LP will

accept either a 6” or 8” (150 mm or 200 mm) HDPE inlet

Pipe. See

Figure 5

.

Product Specifications: 3.1, 3.2, 3.3 and 3.4

FIGURE 4 - Distance Between Corrugations (not to scale)

FIGURE 5 - Chamber End Caps (not to scale)

Summary of Contents for StormTech DC-780

Page 2: ...An company TOOL 2 0 DESIGN ...

Page 39: ......