200S

7

I - 2 Gener

a

l Oper

ations f

o

r 20

0S

General Navigation

Use key pad to enter numeric values within each field.

The ENTER key will confirm the entry within a field, and return to the

previous screen.

Press the C key to clear entries, and error messages, or return back

to the previous screen.

SOFT KEY lables show the various milling, or turning functions.

These functions are selected by pressing the corresponding soft key

directly below each soft key label. There are 3 pages of selectable

soft key functions. These are accessed using the LEFT or RIGHT

arrow keys as indicated below.

LEFT or RIGHT arrow keys move through pages 1-3 of soft key

selectable functions. The current page will be highlighted in the

Status bar at the top of screen.

Use the UP, or DOWN arrow keys to move between fields within a

form, and list boxes within a menu. The orientation of the cursor is

such that it will return to the top once it has reached the bottom of

a menu.

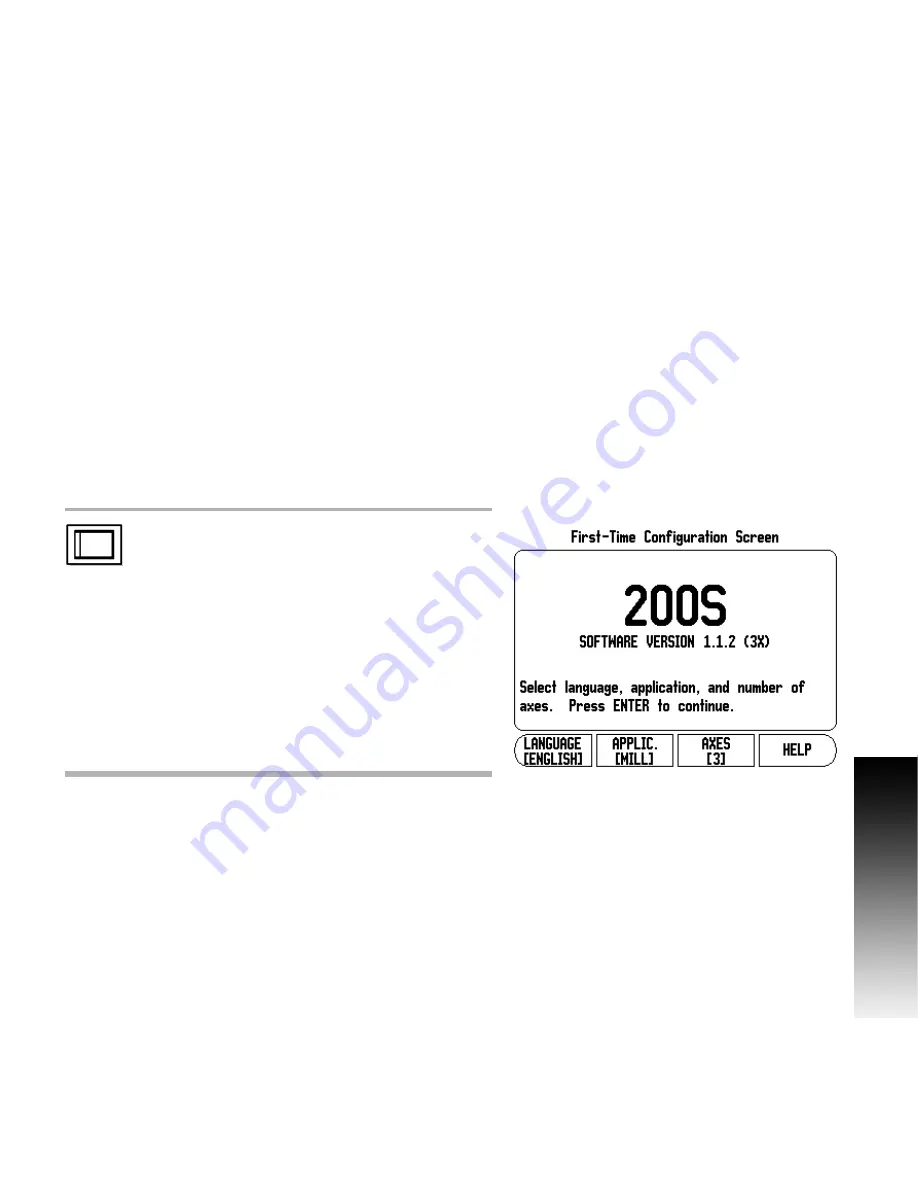

Power Up

Switch on the power (located on the back). The initial

screen will appear (see figure at right). This screen

will only appear the very first time the unit is powered

up. The following steps may have already been

completed by the installer.

Select the proper language by pressing the LANGUAGE soft key.

Choose your application of either MILL or TURN. The APPLIC.

[MILL/TURN] soft key toggles between these two settings.

Next, select the number of axes required. When complete, press

the ENTER hard key.

If necessary, you can change the application later in

Installation Setup under Counter Settings.

The 200S is now ready for the remaining setup requirements. It is

now in the operating mode “Absolute”. Each active axis will have a

flashing“REF”sign next to it. The following section, “Reference Mark

Evaluation”, describes setting up this feature.

Summary of Contents for 200S READOUTS

Page 1: ...200S READOUTS REFERENCE MANUAL ...

Page 2: ......

Page 6: ...iv ...

Page 8: ...vi ...

Page 10: ...viii ...

Page 15: ...1 Operating Instructions ...

Page 58: ...44 I I 4 Turning Specific Operations ...

Page 59: ...45 Technical Information ...

Page 78: ...64 I II 6 Dimensions ...

Page 81: ......