19

Heat sensor:

Typically used with a digital output that has the function "Heat control". The input typically

has a heat sensor fitted which gives a 0-10V output signal. The input is scaled according to what 0V and 10V

correspond to. This defines a low limit at which the heat control must be activated and a high limit at which

heat control is deactivated.

Valve opened:

Used with a digital output that has the function "Open valve", the function is used with

another set of DI/DO, where you can open and close a valve that stops the supply to the pump well,

whereby the inlet pipes can be used as reservoirs in case of increased inflow/rain event etc.

Valve closed:

Used in conjunction with a digital output that has the "Close valve" function. Read the

description above.

General stop:

Used as a general stop function. If the digital goes high it stops the pumps. Can be used in

case of

“

dry running

”

of pumps, where a mechanical stop is activated and stops the pumps.

Digital output

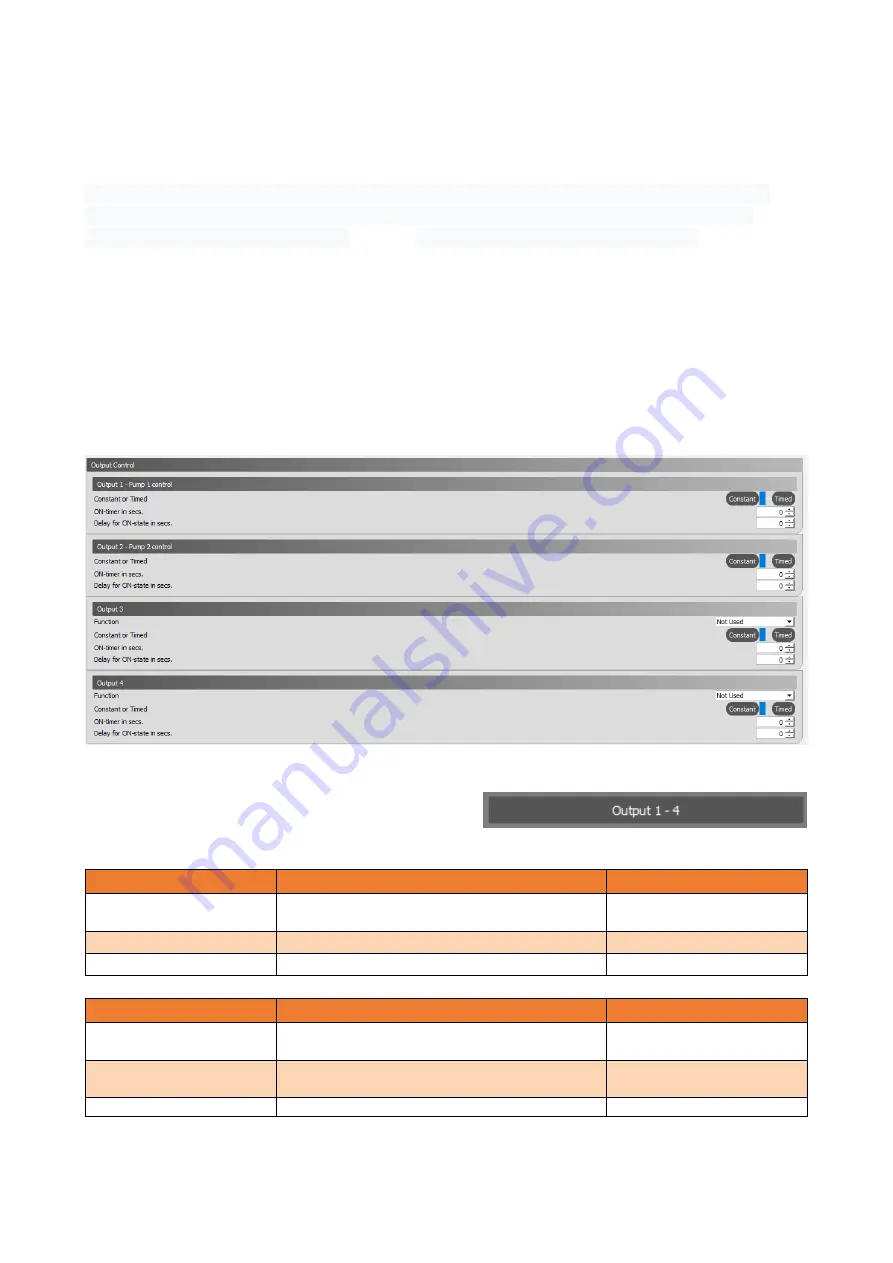

DO 1-2 are relay outputs dedicated to pump control, where DO 3-4 is used for specialized functions.

To configure DO 1-4 click on the button shown below the

Spider image.

DO 1 and 2 settings

Functions

Description

Constant or timed

Choose if DO should be activated for a given period

of time

Can be used for timely

operations

ON-timer in secs.

If timed is chosen, state the wanted period of time

On-timer stated in seconds.

Delay for ON-state in secs.

Signal delay

Delay stated in seconds.

DO 3 and 4 settings

Functions

Description

function

Additional functions

Could be alarm, Washing

pump etc.

Constant or timed

Choose if DO should be activated for a given period

of time

Can be used for timely

operations

ON-timer in secs.

If timed is chosen, state the wanted period of time

On-timer stated in seconds.