page 5

The fan takes in the room air which is then heated

as it passes through the heat exchanger. The

warm air is discharged directly into the environment

through the grille located at the top or front of the

appliance.

Fan operation is controlled by a thermostat: to

prevent cold air from entering the environment.

The fan begins operating shortly after the burner

has ignited. The fan runs for a short time after the

burner is extinguished, to allow the exchanger to

cool off gradually.

If the air filter becomes blocked or if the fan does

not turn on or function correctly, and as a

consequence the exchanger overheats, a safety

device will be triggered that will cut off the gas

flow to the burner. This shutdown condition will

also be indicated on the control panel.

The combustion products are exhausted outdoors

by a centrifugal fan whose correct functioning is

controlled by a differential pressure switch. The

fan is located after the sealed combustion circuit.

The combustion circuit’s pressure is always lower

than the room’s air pressure, thus providing an

additional safety feature.

Air heater operation is controlled by the electronic

room thermostat on the remote-control panel

and by an optional programmable timer that is

installed separately.

1.4 CONSTRUCTION CHARACTERISTICS

The casing is built with epoxy-powder painted

metal plate which guarantees its durability. In

the WD versions with ducts the casing is built

with galvanized metal plate and has removable

inspection panels.

The air delivery side (in the W and WR versions)

has a grille with painted aluminum blades which

can be individually oriented to permit you to

direct the air flow where you want in the room.

The blades are attached to supports made of

heat-resistant plastic. They rotate by means of

an exclusive friction system on silicone guides.

There is a small door to the side of the grille

which, in the W version for installation on the

wall, protects the access to the control panel.

This is especially useful when the unit is installed

in public places, because it prevents the controls

from being set to undesired positions, for

example, by children (the small door is not used

in the ceiling version since the remote-control

panel is installed on the wall).

In the WD versions with ducts the grille and the

adjustable blades have been replaced by an air

outlet that is designed to have ducts attached to

it. Also the air intake side has been designed to

have ducts attached to it.

The air intake side (in the W and WR versions)

houses a filter made of regenerable synthetic

material in a metal frame which can be removed

for cleaning.

The following are installed inside the unit:

- The heat exchanger unit with gas burner.

This module, which was developed using

patented technical solutions, is made of

stainless steel. It is basically made up of a pair

of finned tubes which exchange heat very

efficiently and a combustion chamber which

houses an atmospheric burner which generates

an axial flame. The combustion products are

exhausted outdoors by a centrifugal fan.

- The ventilation unit, which is made up of two

centrifugal fans with double intake. They have

a high air capacity and a low noise level. They

are activated by an electric motor whose

rotation speed is controlled from the control

panel. The unit is mounted on a galvanized

steel support.

- The set of control devices, which includes:

- Burner control unit with electronic ionization

flame detection.

- Gas solenoid valve with a double closing

device and a pressure regulator.

- Differential pressure switch for controlling

that the combustion products are exhausted

properly.

- Fan control thermostat.

- Safety thermostat.

- The control panel (operated by remote

control in the WR and WD versions). It is

able to control the room temperature by means

of a built-in probe and to indicate the

functioning status or any problems with the

unit. It also allows you to select one of its two

ventilation speeds.

1.5 PACKAGE CONTENTS

The unit is shipped in two separate packages:

a) The unit: The air heater is shipped with

cardboard packing and polystyrene foam

protection corners and sheets. For the W

version, for installation on the wall, the

electronic control panel is already installed

on the unit. Instead, for the WR and WD

versions for installation on the ceiling, the

control panel is already connected to the unit

with four meters of cable; the accessories for

page 32

8.4 DIFFERENTIAL PRESSURE SWITCH

Disconnect the electrical connection and the

silicone tubes. Unscrew the screws and remove

the pressure switch. Install the new pressure

switch (which has been calibrated specifically for

your air heater model) and re-establish the

connections, making sure that you place the

contacts in their proper positions. Put the silicone

tube back in place (fig. 27).

8.5 CONVECTION FAN CONTROL

THERMOSTAT

Disconnect the cables and unscrew the

thermostat from the threaded support. Insert the

new thermostat, screwing it all the way in by

hand (do not use tools which might damage the

thermostat). Make sure that the distance between

the thermostat enclosure and the threaded

support is not greater than 3 mm, to guarantee

that the sensor remains in contact with the wall

of the exchanger. Re-establish the electrical

connection (fig. 28).

8.6 SAFETY LIMIT THERMOSTAT

Disconnect the electric connection of the

thermostat on the terminal board. Release the

thermostat by disassembling the attachment

plate from the support. Mount the new thermostat

by reversing the order of the previous operations.

Make sure to insert the side of the thermostat

with the printed data facing the air heater shield

(fig. 29).

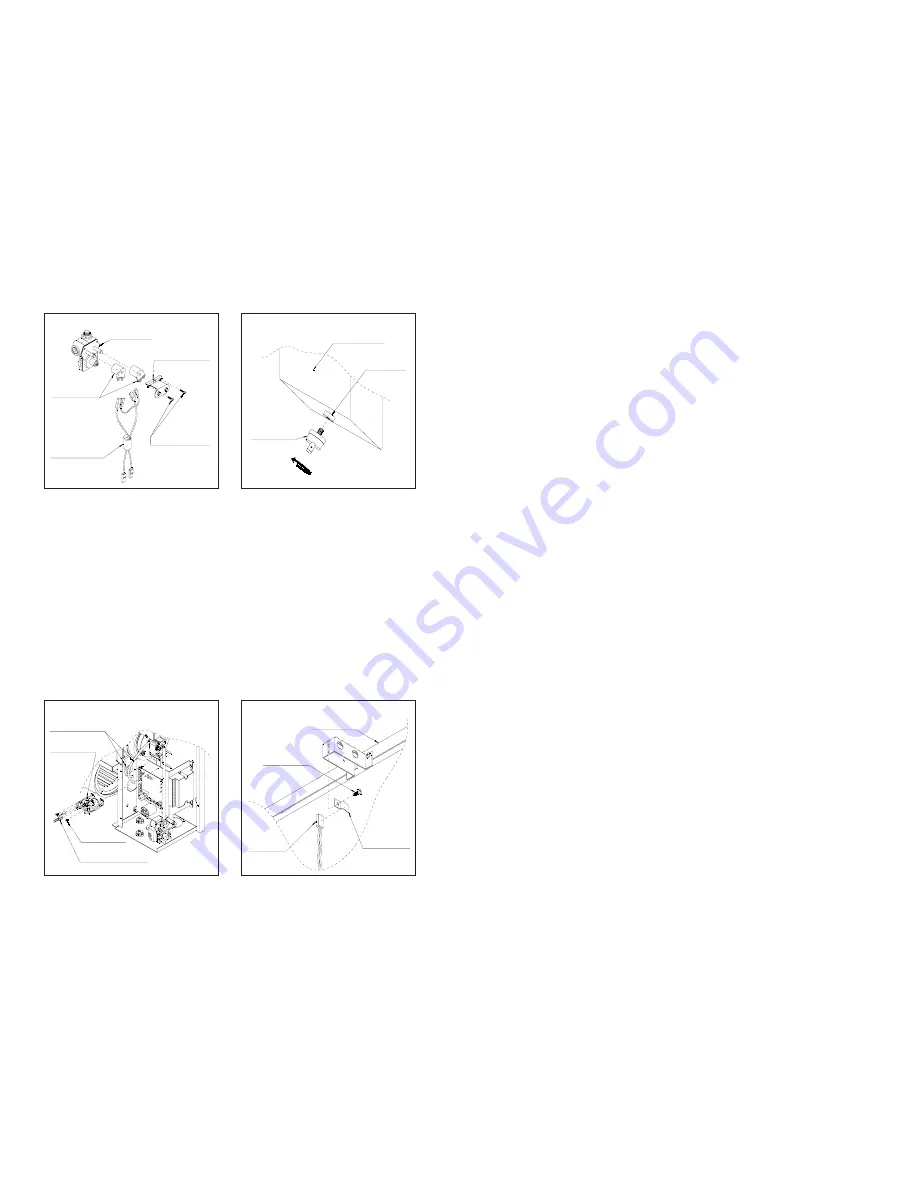

Fig. 28

CHANGING THE FAN THERMOSTAT

Exchanger

Threaded

support

Thermostat

Unscrew

Fig. 27

CHANGING THE PRESSURE SWITCH

Silicone tubes

Pressure switch

Screws

Electrical connection

Fig. 29

CHANGING THE SAFETY THERMOSTAT

Back plate

Thermostat

Screw

Attachment

plate

Fig. 26

CHANGING THE GAS UNIT’S COIL

Coil support

Gas unit

Screws

Solenoid

valve coils

Valve rectifier

bridge

Summary of Contents for W

Page 2: ......