page 8

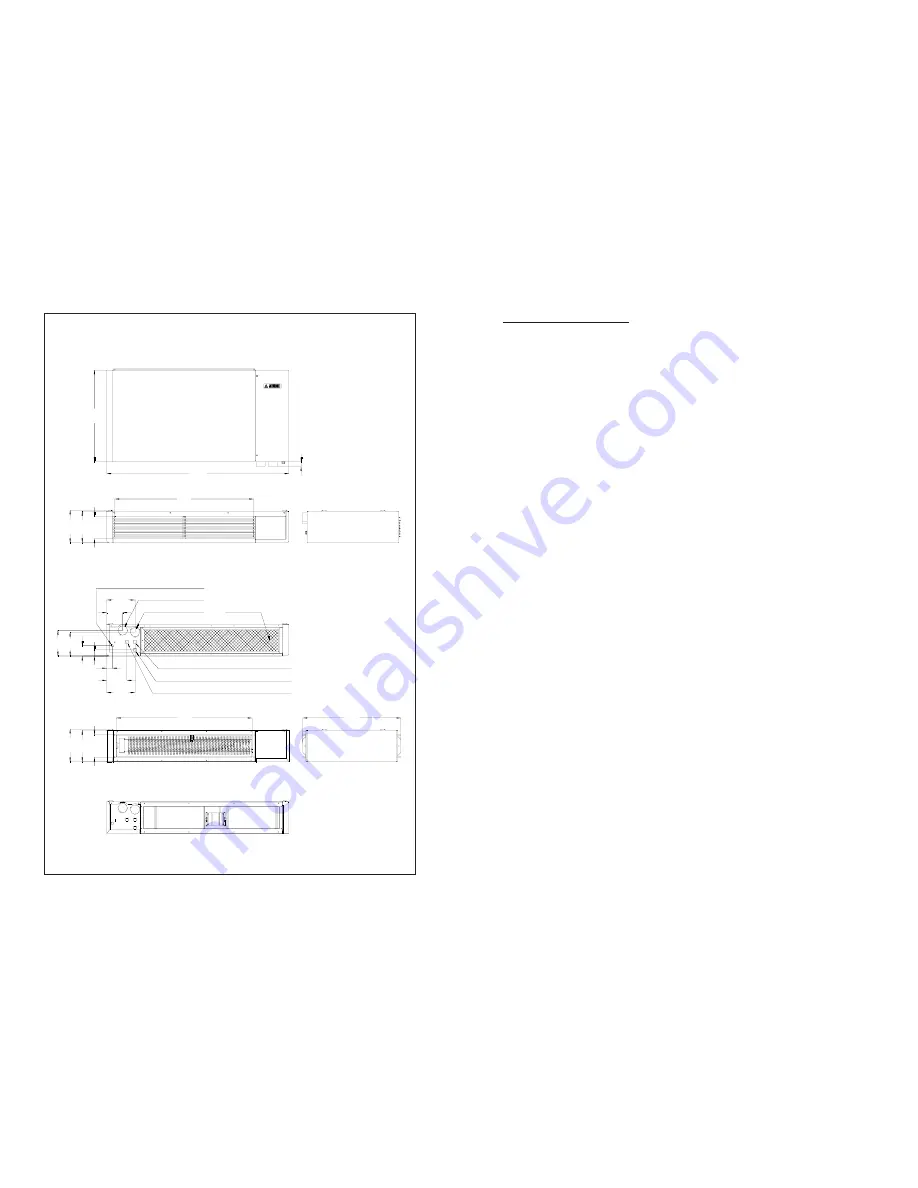

Fig. 1

219

1.220

613

32

212

151

930

38

171

160

69

40

136

190

910

219

212

150

657

1.10 DIMENSIONS - WR and WD versions for ceiling installation

Bottom view of

the WR version

Front view of the WR version

Front view of the WD version

Side view of the WR version

Side view of the WD version

Rear view of the WR version

Rear view of the WD version

ISO 228/1 G1/2”A gas connection

Air intake, Ø 60

190

108

Flue gas discharge, Ø 60

Air filter

Optional timer cable outlet

Electric power supply cable inlet

Control panel cable outlet

page 29

7. OPERATING DEFECTS

7.1 PRELIMINARY TESTS

Before performing specific tests, make sure that:

a) The electric power supply is properly connected

(pay particular attention to the phase-neutral

polarity and ground connector) and that any

external adjustment components (for example,

the programmable timer) function correctly.

b) The gas supply is correct, the gas on-off valve

is open, and the pressure to the burner

corresponds to what is indicated in the

technical data table.

c) The external terminals of the combustion air

intake duct and the combustion product

exhaust flue are not obstructed and that the

material they are made of has not deteriorated.

d) The control panel functions correctly.

7.2 POSSIBLE DEFECTS

The following is a list of possible defects along

with their probable causes. The information

indicated in italics refers to repair operations or

corrections which are the responsibility of the

authorised Technical Service Centre.

7.2.1 The appliance does not start even if the

conditions described in the previous

points are correct.

a) the flame detection circuit of the control

equipment is malfunctioning and the initial self-

check does not allow the cycle to continue.

-

Replace the control equipment (see point

8.1).

b) The flame detection electrode has an earth

leakage.

-

Check the correct position of the electrode.

The ceramic insulation material may be

cracked and this is difficult to determine

visually. In case of doubt, replace the electrode

(see point 8.7).

c) The differential pressure switch’s contacts

are frozen in the position they assume when

the draft is correct.

-

Change the pressure switch if its microswitch

does not reset the contacts to the proper

position (see point 8.4).

d) The flue gas expeller fan’s motor has failed

and the differential pressure switch will not

allow startup to proceed.

-

Change the fan. Be careful to reassemble the

unit as shown in figure 31 (see point 8.8).

7.2.2 The control equipment does not shut

down, but the cycle remains in a

continuous preventilation phase

a) The differential pressure switch will not allow

startup to proceed because the flue gas

exhaust flue or the air supply duct is

obstructed.

-

First eliminate any obstructions from the

terminals. In any case check the entire path of

the ducts for damage or alterations.

b) The differential pressure switch will allow

startup to proceed because the flue gas

expeller fan does not function correctly and

does not develop enough suction.

-

Check to see if there are any problems of

wear with the rotation of the fan motor. Make

sure that the fan is positioned correctly, that

there is nothing that interferes with the rotation,

and that there are not any deformations. If

necessary, change the fan. Be careful to

reassemble the unit as shown in figure 31

(see point 8.8).

c) The differential pressure switch will not allow

startup to proceed because it is broken or its

electrical connection has been interrupted.

-

Check that the connection cable and the

corresponding terminals are in good condition.

Do not attempt to adjust the pressure switch

by removing the seal; instead, change it.

d) The differential pressure switch will not allow

startup to proceed because the pressure inlet

tube is obstructed or the silicone connection

tube is disconnected or broken.

-

Make sure that the silicone tube is connected

correctly and that it does not have any holes

or cuts in it. If it is not damaged, check the

steel pressure inlet tube and remove any

obstructions or deposits from it. It will be

necessary to access the inside of the

exchanger’s flue gas collector to completely

carry out this operation.

7.2.3 At the end of the preventilation phase,

the ignition electrodes do not discharge

and the control equipment shuts down

within the safety time

a) The ignition transformer is malfunctioning.

-

Replace the controller which contains the

transformer. Because these are electronic

components, it is advisable not to attempt to

replace just the transformer, especially if you

do not use the proper tools.

Summary of Contents for W

Page 2: ......